An electrochemical comprehensive treatment process for high-concentration and refractory organic wastewater

A technology for comprehensive treatment of organic wastewater, applied in water/sewage treatment, neutralized water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problem of affecting treatment efficiency, easy passivation of plates, and unsatisfactory Fenton reaction effects To achieve broad-spectrum treatment effect, avoid plate passivation, improve power efficiency and wastewater treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

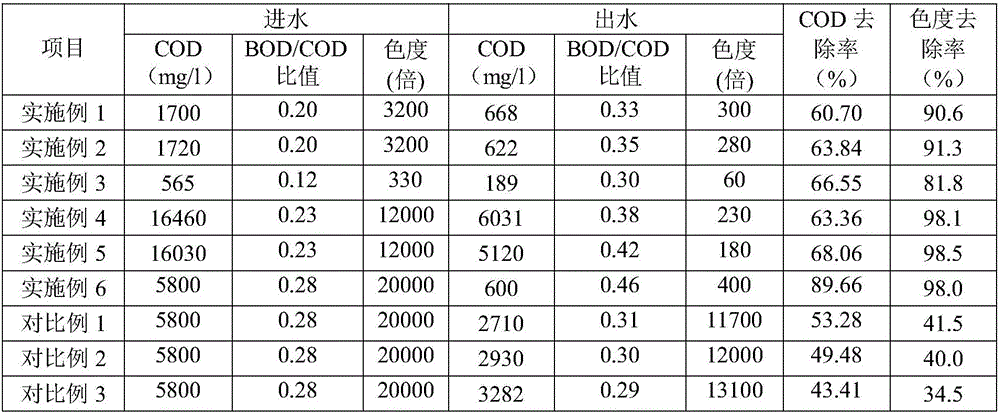

Examples

Embodiment 1

[0036] Embodiment 1. Electrochemical comprehensive treatment process of high concentration and refractory organic wastewater of the present invention

[0037] Treatment of landfill leachate reverse osmosis concentrated water, the treatment capacity is 0.5m 3 / h, raw water conductivity: 24400μs / cm, COD: 1700mg / l.

[0038] S1. Adjust the pH value of the wastewater to 2.0, then the wastewater enters the electrocoagulation tank, and the adjustable pulsed direct current is passed to the positive and negative iron plates in the electrocoagulation tank for electrocoagulation oxidation treatment; the positive and negative iron plates use Repolarization series structure, and connected to the timing inverted power supply, the positive and negative exchange cycle of the plates is 20min, the distance between the plates is 1.0cmcm, and the current density is adjusted to 20mA / cm 2 , the residence time is 10min, and the waste water after the first oxidation is obtained;

[0039] S2, the wa...

Embodiment 2

[0043] Embodiment 2, the electrochemical comprehensive treatment process of high concentration and refractory organic wastewater of the present invention

[0044] Treatment of landfill leachate reverse osmosis concentrated water, the treatment capacity is 0.5m 3 / h, raw water conductivity: 26780μs / cm, COD: 1720mg / l.

[0045] S1. Adjust the pH value of the wastewater to 4.5, then the wastewater enters the electrocoagulation tank, and the adjustable pulse direct current is passed to the positive and negative iron plates in the electrocoagulation tank for electrocoagulation oxidation treatment; the positive and negative iron plates use Repolarized series structure, and connected to the timing inverted power supply, the positive and negative exchange cycle of the plates is 20min, the distance between the plates is 1.5cm, and the adjusted current density is 50mA / cm 2 , the residence time is 30min, and the waste water after the first oxidation is obtained;

[0046] S2, the waste w...

Embodiment 3

[0050] Embodiment 3, the electrochemical comprehensive treatment process of high concentration and refractory organic wastewater of the present invention

[0051] Treat landfill leachate MBR effluent with a treatment capacity of 0.5m 3 / h, raw water conductivity: 14680μs / cm, COD: 565mg / l.

[0052]S1. Adjust the pH value of the wastewater to 2.5, then the wastewater enters the electrocoagulation tank, and the adjustable pulsed direct current is passed to the positive and negative iron plates in the electrocoagulation tank for electrocoagulation oxidation treatment; the positive and negative iron plates use Repolarized series structure, and connected to the timing inverted power supply, the positive and negative exchange cycle of the plates is 20min, the distance between the plates is 1.5cm, and the adjusted current density is 30mA / cm 2 , the residence time is 20min, and the waste water after the first oxidation is obtained;

[0053] S2, the waste water after the first oxidati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com