Self-driven heat pipe circulation heat exchanger

A heat pipe circulation and self-driving technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of difficult normal operation of gravity circulation heat pipes, inability to achieve continuous operation, complex structure, etc., to avoid power plant control problems, The effect of expanding the scope of circulation application and occupying a small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

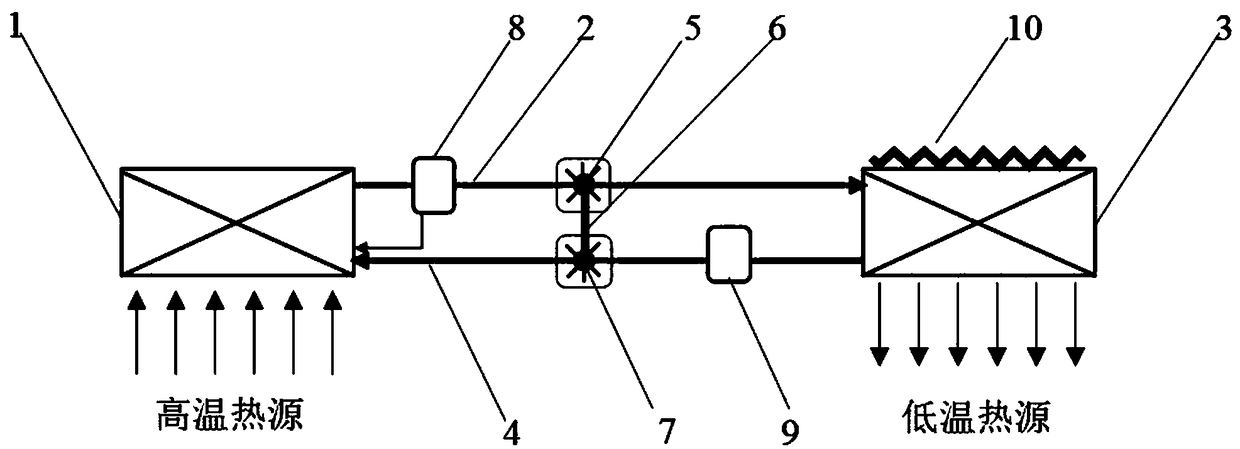

[0028] Embodiments of the present invention provide a self-driven heat pipe circulation heat exchanger, such as figure 1 shown, including:

[0029] Evaporator 1, gas pipe 2, condenser 3, liquid pipe 4, driving wheel 5, rotating shaft 6, driven wheel 7.

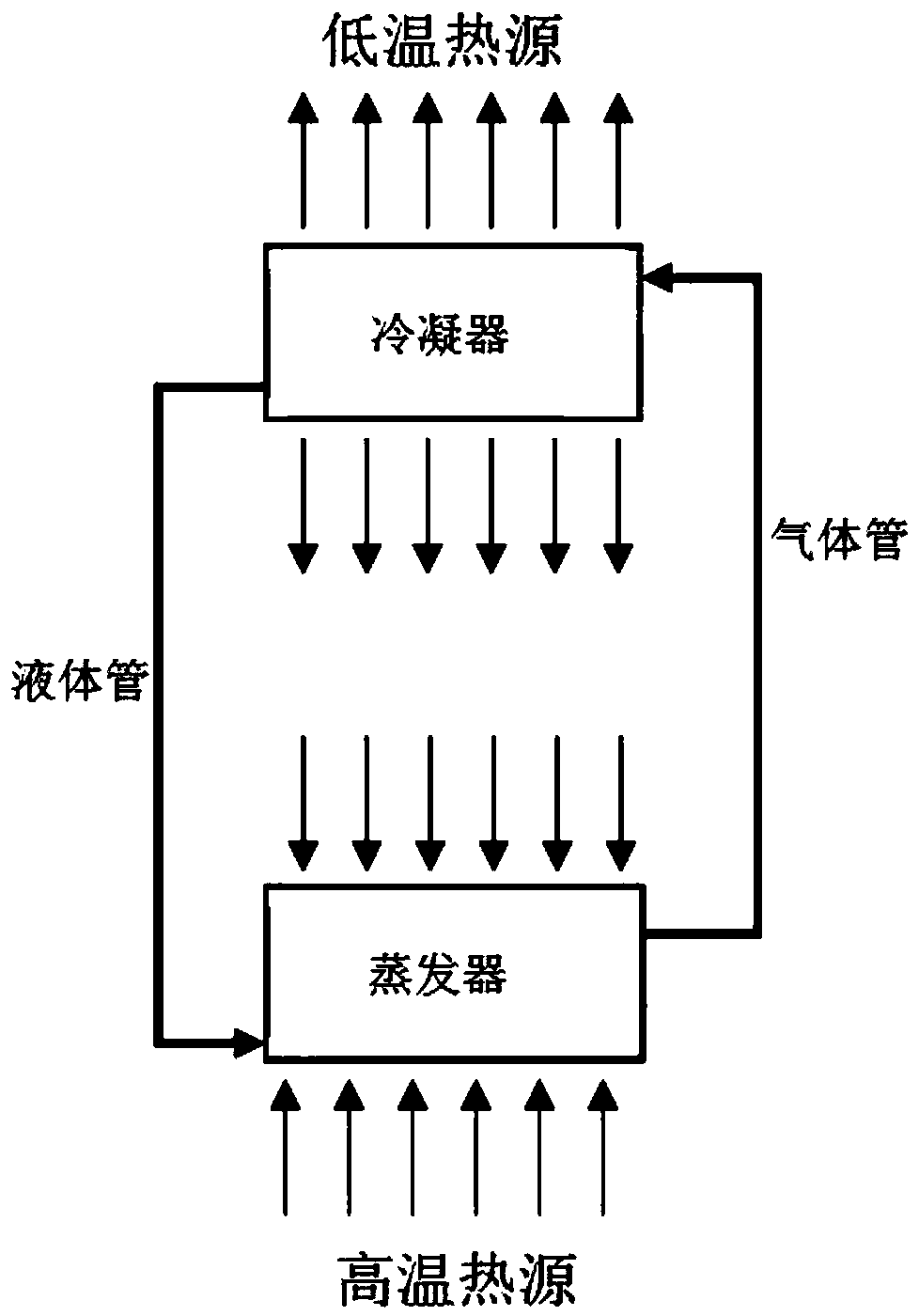

[0030] The evaporator 1 is connected to the condenser 3 through a gas pipe 2 and a liquid pipe 4 to form a closed space that can circulate, and the closed space is filled with a phase change working medium.

[0031] An electric heating band 10 is arranged on the condenser 3 . Before starting, the working medium is in the condenser 3. In order to start smoothly, start the electric heating belt 10 to heat the working medium in the condenser 3, so that the working medium is in the evaporator 1 before s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com