Back contact structure of cadmium telluride thin-film solar cell, solar cell, cell assembly, and preparation method

A thin-film solar cell, back-contact structure technology, applied in electrical components, circuits, photovoltaic power generation, etc., can solve problems such as high resistivity and unsatisfactory batteries, and achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The back contact structure of the present invention is 0.5Mo 2 N-0.5MoO 2 battery.

[0025] Preparation method and conditions: 120nm thickness prepared by magnetron sputtering, Ar / O2 / N2=0.95 / 0.02 / 0.03, sputtering pressure 2.5Pa, substrate temperature 150 degrees, sputtering power 200W.

[0026] After sputtering 0.5Mo 2 N-0.5MoO 2 Post-layer annealing, the annealing temperature is 200 degrees, and the annealing time is 40 minutes.

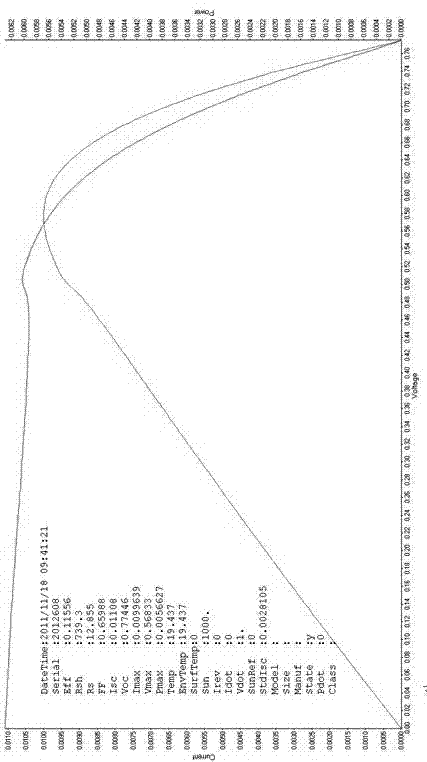

[0027] according to figure 1 As shown, the J-V test results are as follows, the efficiency can reach 11.556%, the open circuit voltage is 775mV, the fill factor is 0.66, and the short circuit current is 22.48mA / cm 2 .

Embodiment 2

[0034] The back contact junction is Cu / 0.5Mo 2 N-0.5MoO 2 battery.

[0035] Preparation conditions:

[0036] Cu layer: 5nm prepared by magnetron sputtering, sputtering pressure: 2.4Pa, substrate temperature: room temperature, power: 100w (round target with a diameter of 110mm).

[0037] 0.5Mo 2 N-0.5MoO 2 Layer: 120nm thick prepared by magnetron sputtering, Ar / O2 / N2=0.95 / 0.02 / 0.03, sputtering pressure is 2.5Pa, substrate temperature is 150 degrees, sputtering power is 200W.

[0038] After sputtering 0.5Mo 2 N-0.5MoO 2 Post-layer annealing, the annealing temperature is 200 degrees, and the annealing time is 40 minutes.

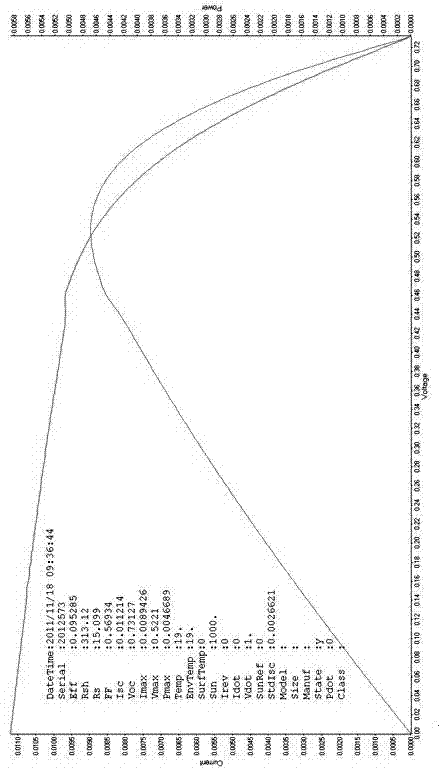

[0039] according to image 3 As shown, the J-V test results are as follows, the efficiency can reach 13.15%, the open circuit voltage is 786mV, the fill factor is 0.67, and the short circuit current is 23.97mA / cm 2 .

[0040] Comparative example:

[0041] The back contact structure is Cu / Mo 2 N battery.

[0042] Preparation conditions:

[0043] C...

Embodiment 3

[0049] A cell with a back contact junction of 0.7MoN-0.3MoO3.

[0050] Preparation method and conditions: 120nm thickness prepared by magnetron sputtering, Ar / O2 / N2=0.94 / 0.04 / 0.02, sputtering pressure 2.5Pa, substrate temperature 150 degrees, sputtering power 200W.

[0051] After sputtering 0.7MoN-0.3MoO 3 After layer annealing, the annealing temperature is 220 degrees

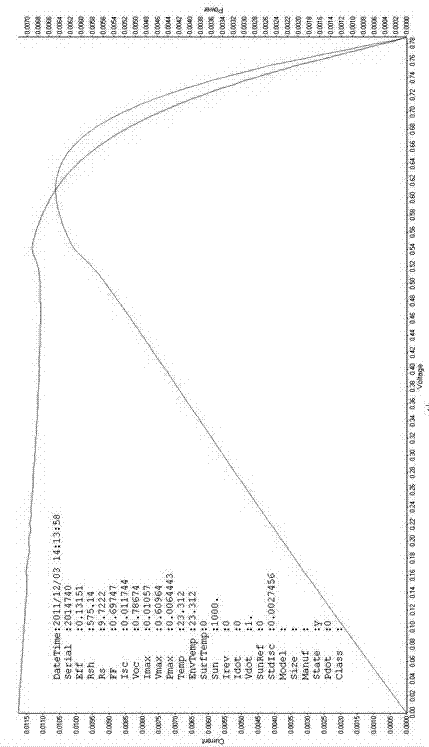

[0052] according to Figure 5 As shown, the J-V test results are as follows, the efficiency can reach 10.834%, the open circuit voltage is 789mV, the fill factor is 0.615, and the short circuit current is 22.3mA / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Short circuit current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com