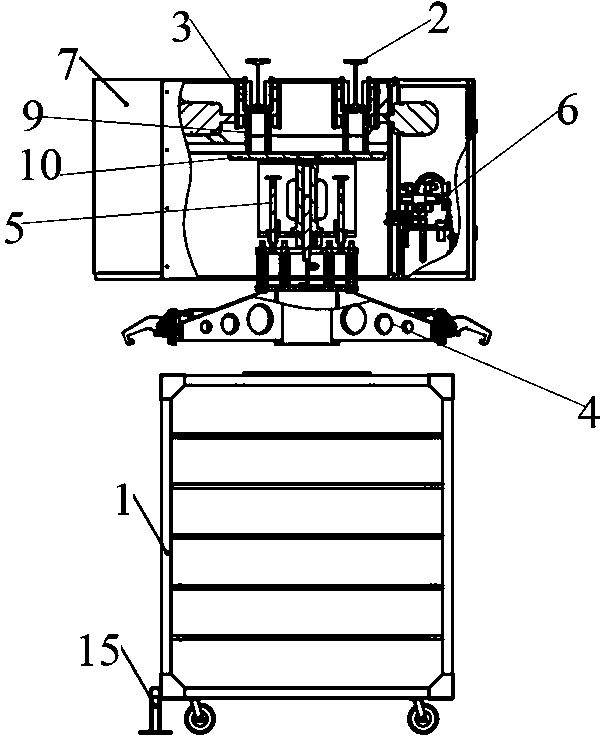

Handling system of dry trolley used for placing denitration catalyst

The technology of denitration catalyst and handling system is applied in the field of handling system of drying trolley for placing denitration catalyst, which can solve the problems of difficulty in manual cart and easy damage of catalyst, and achieve the effect of good economic benefit, good promotion and practical value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

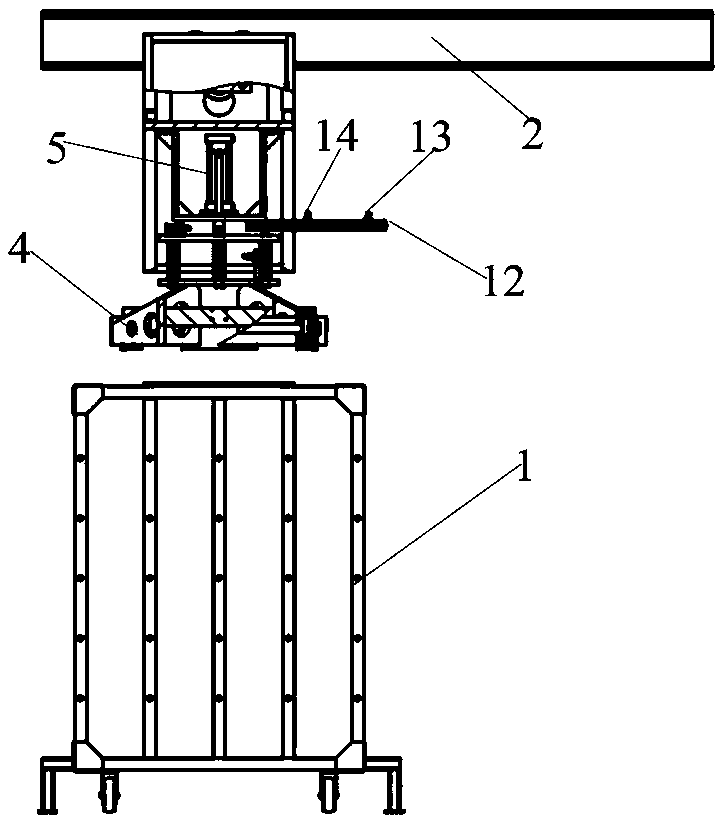

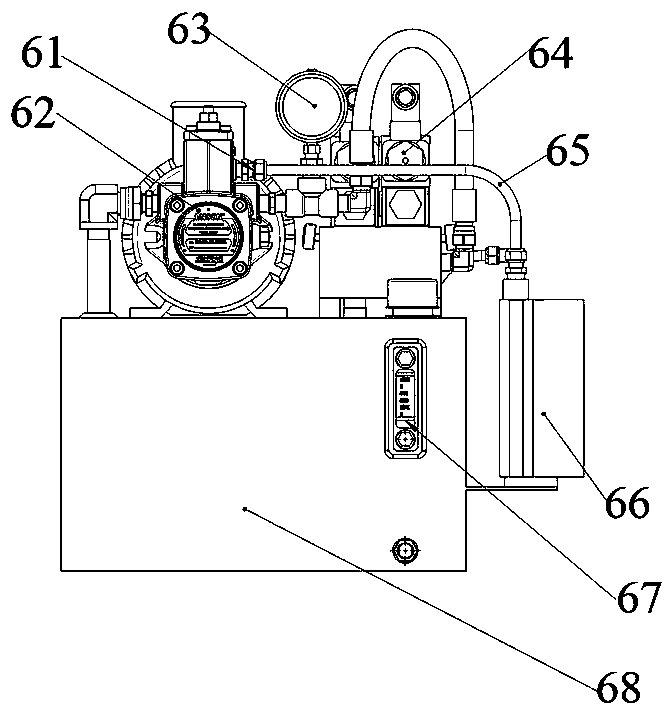

Method used

Image

Examples

Embodiment approach 1

[0049] Select 326 batches of honeycomb catalyst products manufactured by the applicant, and cut them into experimental samples with a length of 800 mm and a cross-sectional size of 25×25 mm. And put it on the trolley according to the layout of 6x6, first push the trolley into the mechanical positioning point (the mechanical positioning structure), after the transplanting and handling device is powered on as a whole, after remote control through the remote control, the transplanting and handling device will change from the original 20 m / min The speed quickly approaches a dry trolley. After the deceleration sensor gets the signal, the speed drops to 5 m / min and slowly approaches the dry trolley. After the stop sensor gets the signal, the transplanting and handling device stops running, and the gripper part automatically opens and descends to reach the specified height. The rear jaws are automatically closed, and the trolley is slowly lifted. After the above work is completed, th...

Embodiment approach 2

[0052] Most of the state and parameter settings of the device are the same as those in Embodiment 1, the difference is that it is to test whether the time required for transporting semi-finished catalysts up to 1200mm (basically the maximum length) and the longest distance (drying room No. 1) can meet the requirements for use. Through experiments, the transplanting and transporting device takes 4 minutes.

Embodiment approach 1

[0054] Select 326 batches of honeycomb catalyst products manufactured by the applicant, cut them into experimental samples with a length of 800 mm and a cross-sectional size of 25×25 mm, and place them on a dry cart in a 6×6 arrangement. Push it into the No. 12 drying room by manual cart, and it takes 8 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com