Process for treating dinaphthol wastewater by using complexation extraction method

A technology for wastewater treatment and binaphthol, which is applied in the direction of extraction water/sewage treatment, water/sewage treatment, water/sewage multi-stage treatment, etc. Toxicity and other issues

Inactive Publication Date: 2013-02-20

SHANGHAI BIOFIT ENVIRONMENTAL TECH

View PDF3 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The main synthesis process of 2-naphthol is: naphthalene sulfonation, hydrolysis, naphthalene blowing, neutralization and other processes. There are many processes, long process, and a large amount of three wastes. Among them, the wastewater has complex components, high concentration, high toxicity, deep color, acidity, etc. It has the characteristics of strong alkali buffering, difficult biochemical degradation and great harm to human body and environment

However, the resulting environmental pollution has not been effectively resolved

The use of macroporous resin adsorption is expensive (45,000 yuan / ton), frequent regeneration is required, and the amount of regenerated black liquor is too large to recover useful components; the COD removal rate continues to decline after the resin adsorption process has been running for a period of time; there are large resin consumption and analysis The amount of black liquor is large, valuable components cannot be recovered, and the consumption and cost of frequent resin regeneration agents are high. After resin adsorption treatment, the effluent is unstable, and the cost of wastewater treatment is as high as 120-150 yuan / m 3 , failed to meet the requirements of discharging into the municipal pipe network, the defect of high operating costs

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Login to View More

Abstract

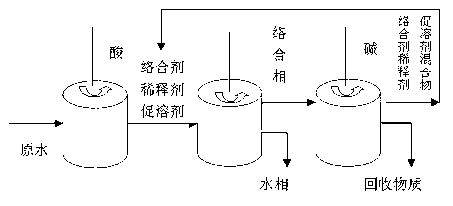

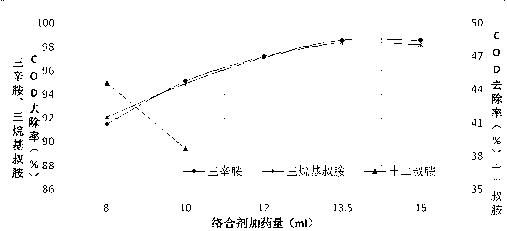

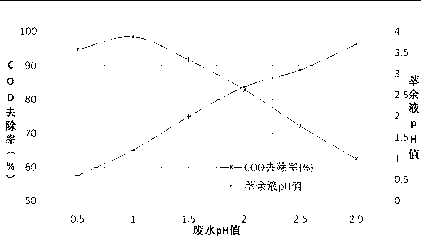

The invention discloses a process for treating dinaphthol wastewater by using a complexation extraction method. A process core includes that trioctylamine or trialkyl tertiary amine serves as a complexing agent, sulfonated kerosene serves as a diluent, and chloric acid tributyl ester serves as a chaotropic agent to be mixed according to a certain ratio into an extraction agent, the extraction agent comprises, by volume, 20% to 30% of the complexing agent, 60% to 70% of the diluent and 5% to 15% of the chaotropic agent. Dinaphthol production wastewater is extracted when the temperature is in a range of 20 DEG C to 30 DEG C and the pH is 1, aqueous phase: oil phase is 1: 1 (volume ratio), the removal rate of first extraction CODcr can reach 97%, naphthalene sulfonate in wastewater can be extracted through multistage extraction, and simultaneously water is discharged up to standard. Water phases of back extraction can be recycled as production materials; and organic phases are mixtures of the extraction agent and the diluent and can be recycled.

Description

technical field [0001] The invention relates to a process for treating dinaphthol wastewater by a complex extraction method, belonging to the technical field of water treatment. Background technique [0002] With the development of society, the problem of shortage of water resources is becoming more and more serious, and water will become an important factor restricting social development. People are also paying more and more attention to the development and improvement of water treatment technology. With the development of water treatment technology, ordinary wastewater can be treated very well by the current technology, but some difficult-to-treat wastewater needs further research, and the treatment of 2-naphthol production wastewater is one of them. [0003] 2-Naphthol, also known as β-naphthol and ethyl naphthol, is an important organic chemical raw material and dye intermediate, mainly used in dyes, organic pigments, rubber antioxidants, and pharmaceutical and pesticid...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C02F1/26C02F1/58C02F9/04

Inventor 不公告发明人

Owner SHANGHAI BIOFIT ENVIRONMENTAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com