Test method of board-level tpms launch module batch test system

A technology of transmitting modules and batch testing, which is applied in the direction of measuring electricity, measuring devices, and measuring electrical variables, etc. It can solve the problems of huge detection pressure, labor cost pressure and material pressure, and achieve the effect of shortening the time for environmental preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

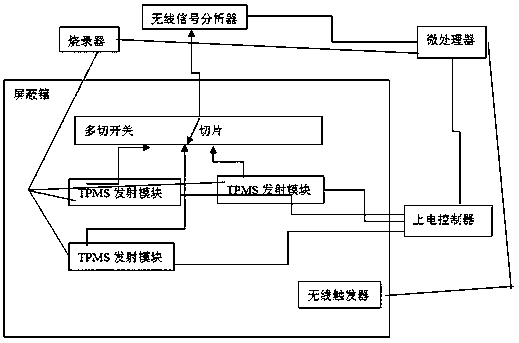

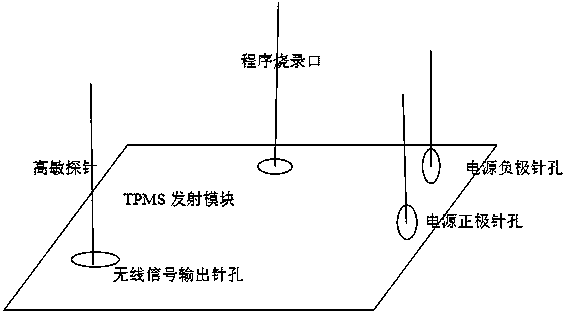

[0019] see figure 1 — figure 2 , the present invention relates to a batch test system for board-level TPMS transmitting modules, including a burner, a shielding box, a wireless signal analyzer, a wireless trigger and a microprocessor, wherein the burner mainly provides automatic programming for the TPMS transmitting module Function, the shielding box is mainly used to shield the wireless signal to ensure the accuracy of the test system signal, the wireless signal analyzer is used to analyze the strength, power, peak value, error and data content of the wireless signal, and the wireless trigger is used to trigger the TPMS transmitting module to transmit wireless signal, the microprocessor is mainly used to issue control commands and receive test content, a mold for fixing the TPMS transmitting module is set inside the shielding box, and high-sensitivity probes are set in the wireless signal output pinhole of the TPMS transmitting module, all The high-sensitivity probes conver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com