Comprehensive treatment and resource utilization technology of 2-naphthol production wastewater

A technology for production wastewater and comprehensive treatment, which is applied in natural water treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of complex components, large investment in equipment, and no recycling of resources. To achieve a reasonable effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

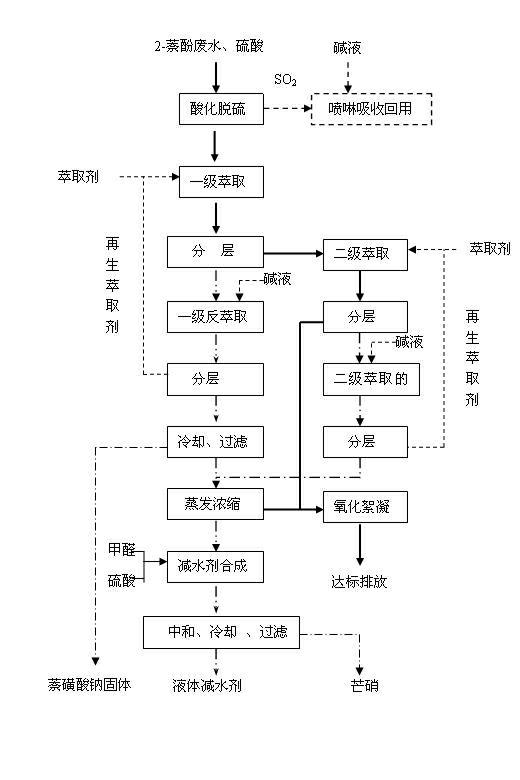

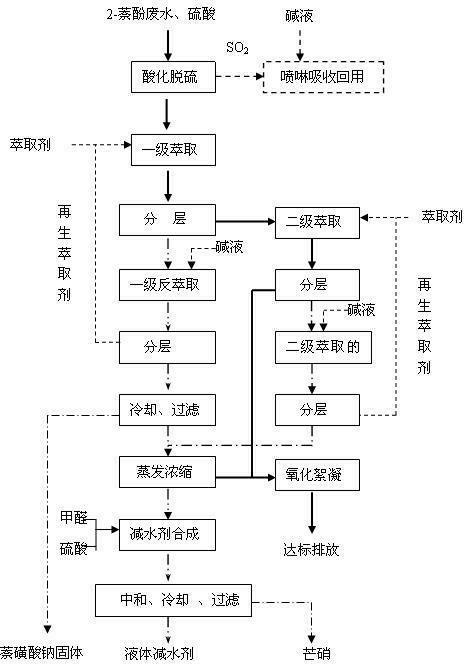

[0028] Embodiment 1, with reference to figure 1 , 2-naphthol production wastewater comprehensive treatment and resource utilization process, its steps are as follows:

[0029] (1) Acidification desulfurization: 2-naphthol production wastewater is directly acidified with inorganic acid to pH 2, and the released SO 2 The gas is sprayed and absorbed with inorganic lye, and the generated sulfite solution is reused in the 2-naphthol production system;

[0030] (2) Primary extraction and back extraction: After the desulfurized wastewater is filtered to remove insoluble matter, it is fully mixed with the extraction agent at a ratio of 1:1 to oil and water under normal temperature and pressure, and the raffinate phase after stratification is sent to the second stage after extraction. Extraction; the extraction phase is the loaded extractant under normal pressure and heated to 60°C with the inorganic lye and fully mixed, the amount of alkali added in the back extraction is based on c...

Embodiment 2

[0036] Embodiment 2, with reference to figure 1 , 2-naphthol production wastewater comprehensive treatment and resource utilization process, its steps are as follows:

[0037] (1) Acidification desulfurization: 2-naphthol production wastewater is directly acidified with inorganic acid to pH 3, and the released SO 2 The gas is sprayed and absorbed with inorganic lye, and the generated sulfite solution is reused in the 2-naphthol production system;

[0038] (2) Primary extraction and back extraction: After the desulfurized wastewater is filtered to remove insoluble matter, it is fully mixed with the extraction agent at a ratio of 5:1 to oil and water under normal temperature and pressure, and the raffinate phase after stratification is sent to the secondary stage after extraction. Extraction; the extraction phase is the loaded extractant under normal pressure and heated to 90°C with the inorganic lye and fully mixed, the amount of alkali added for the back extraction is based ...

Embodiment 3

[0044] Embodiment 3, with reference to figure 1 , 2-naphthol production wastewater comprehensive treatment and resource utilization process, its steps are as follows:

[0045] (1) Acidification desulfurization: 2-naphthol production wastewater is directly acidified with inorganic acid to pH 2.5, and the released SO 2 The gas is sprayed and absorbed with inorganic lye, and the generated sulfite solution is reused in the 2-naphthol production system;

[0046] (2) Primary extraction and back extraction: After the desulfurized wastewater is filtered to remove insoluble matter, it is fully mixed with the extraction agent at a ratio of 3:1 to oil and water under normal temperature and pressure, and the raffinate phase after stratification is sent to the secondary stage after extraction. Extraction; the extraction phase is the loaded extractant under normal pressure and heated to 75°C with the inorganic lye and fully mixed, the amount of alkali added for the back extraction is base...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com