Mineral admixture concrete

A mineral admixture and concrete technology, applied in solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems of low overall utilization level, less than 80% utilization, obstruction of traffic, rivers, etc. , to achieve significant social and economic benefits, reduce cement consumption, and increase compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

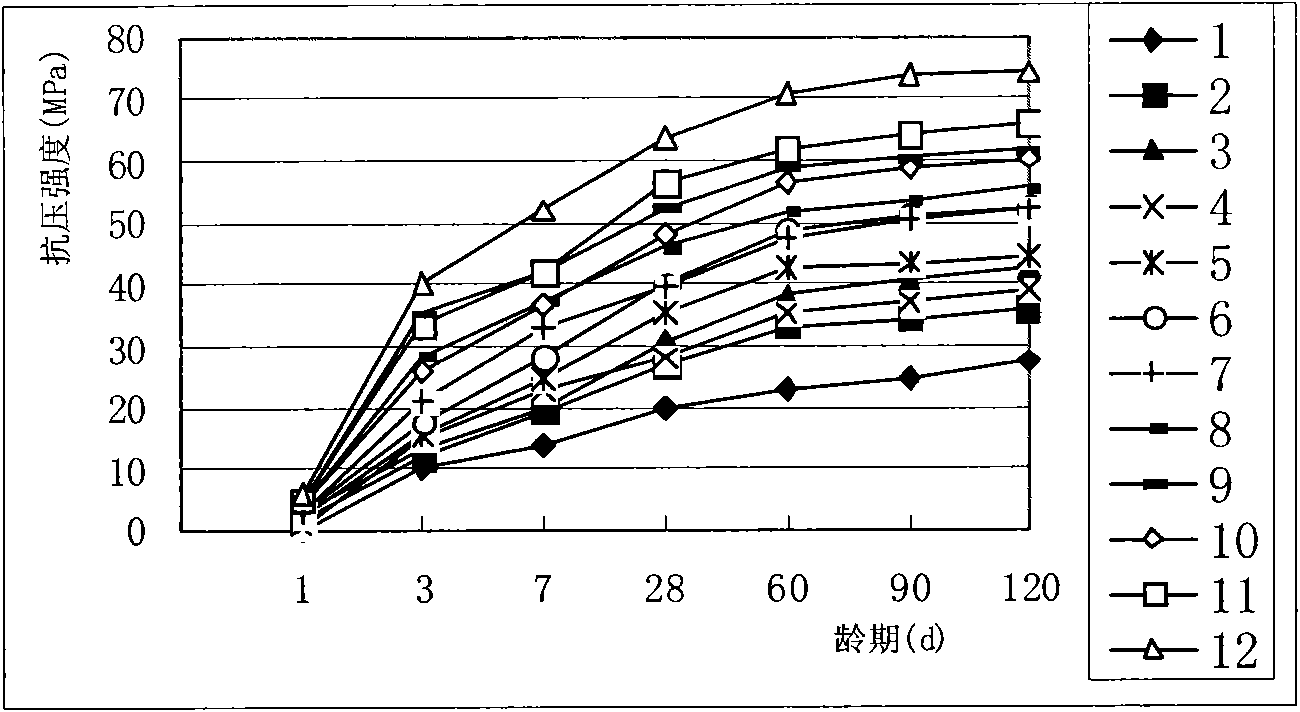

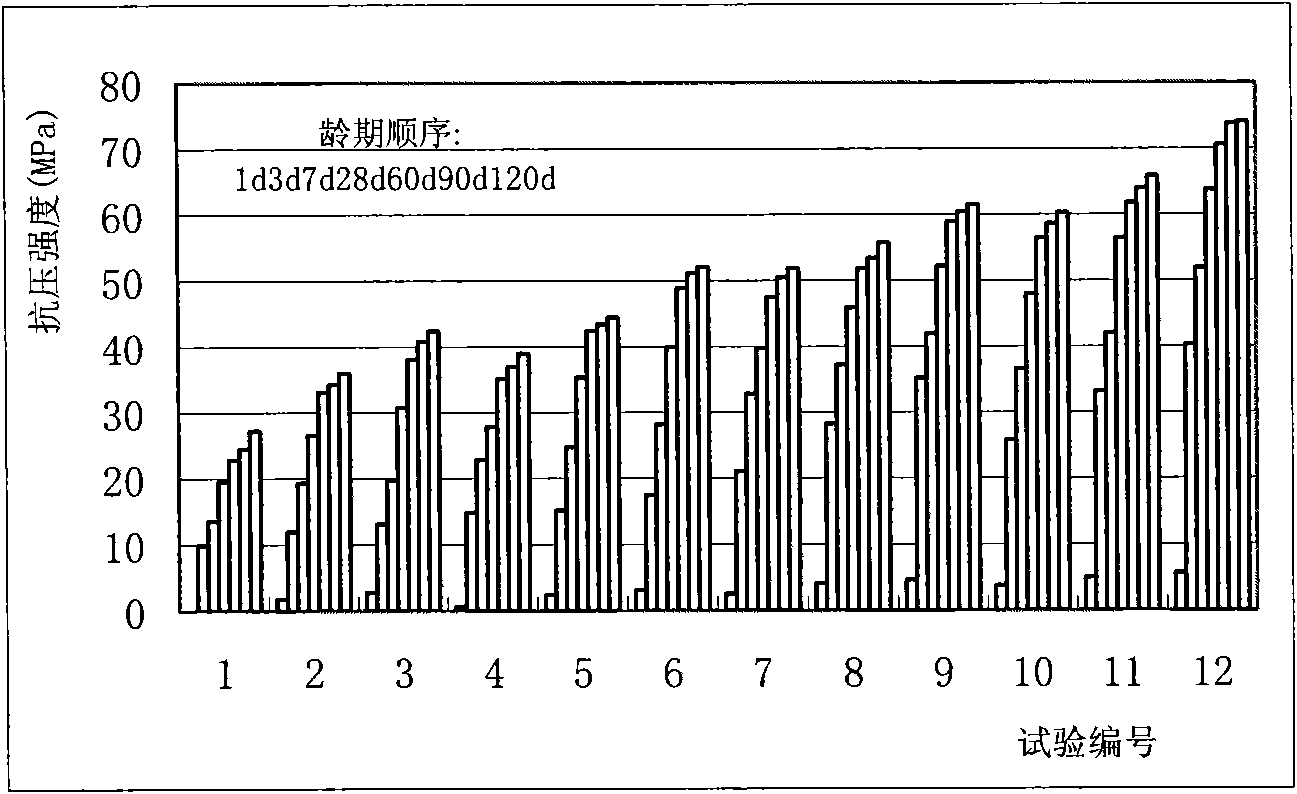

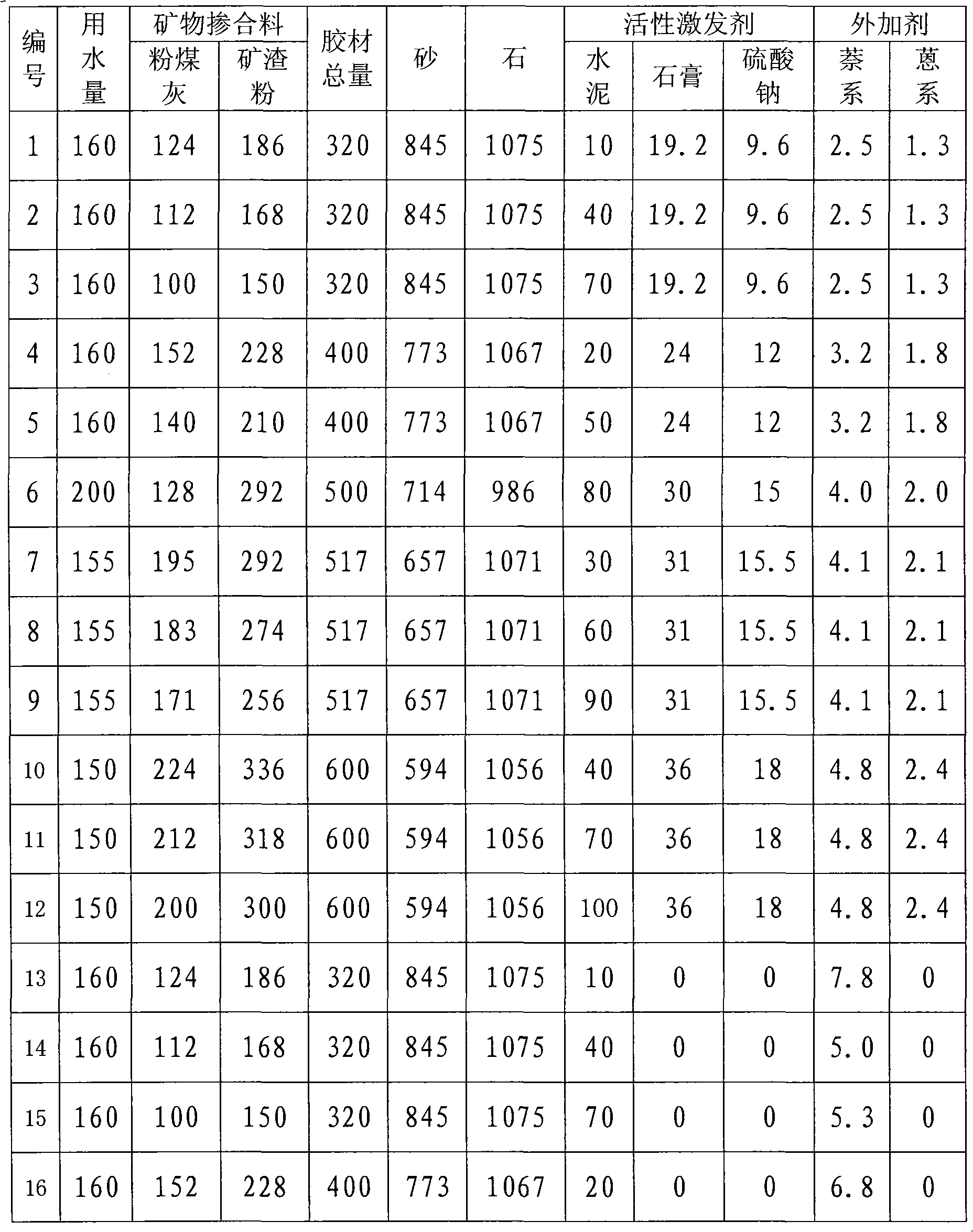

[0051] The water-binder ratio is selected as 0.50, 0.40, 0.30, 0.25 respectively, and the water consumption is controlled at 150-160kg / m 3 ; The ratio of fly ash and slag powder in the mineral admixture is 2:3; the compound of ordinary Portland cement, industrial gypsum and industrial sodium sulfate is used as the active stimulator of the mineral admixture, and the cement dosage is 10- 100kg / m 3 , the ratio of gypsum to sodium sulfate is 2:1; the admixture is naphthalene sulfonate formaldehyde condensate superplasticizer and crude anthracene sulfonate superplasticizer, the ratio of the two is 2:1. The concrete mix ratio is shown in the ratio 1-12 in Table 1. For comparison, we specially formulated the ratio of using no active stimulant and using commonly used naphthalene-based water reducers, see the ratios 13-24 in Table 1. Conduct concrete mixture workability, 1d, 3d, 7d, 28d, 60d, 120d age compressive strength tests.

[0052] Table 1 Concrete mix ratio kg / m 3

[0053] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com