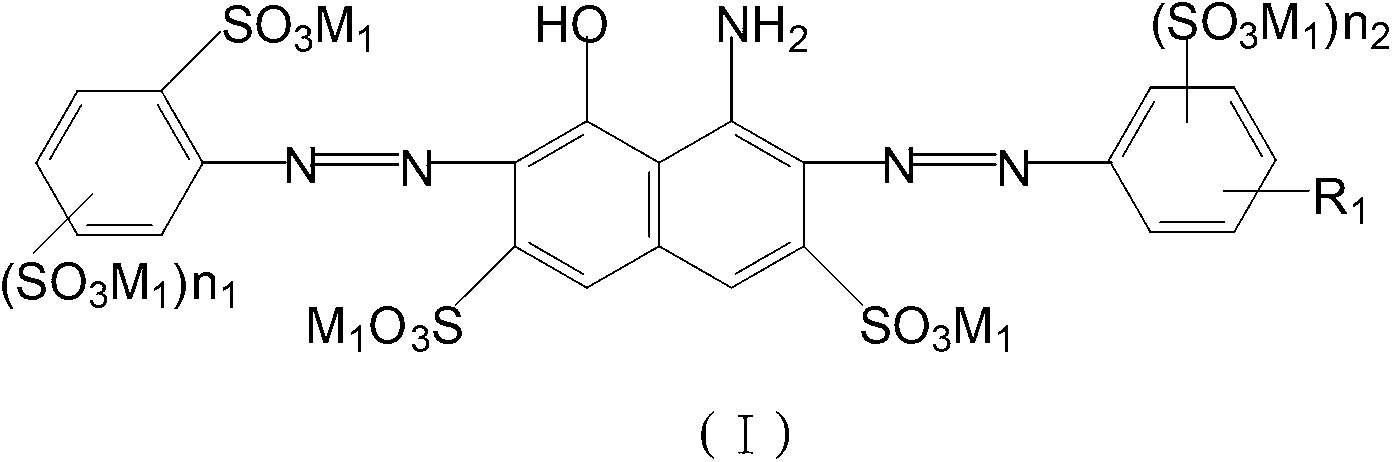

Black reactive dye composition

A technology of reactive dyes and compositions, which can be used in organic dyes, dyeing methods, textiles and papermaking, etc., and can solve problems such as unsatisfactory dyeing properties of dyes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

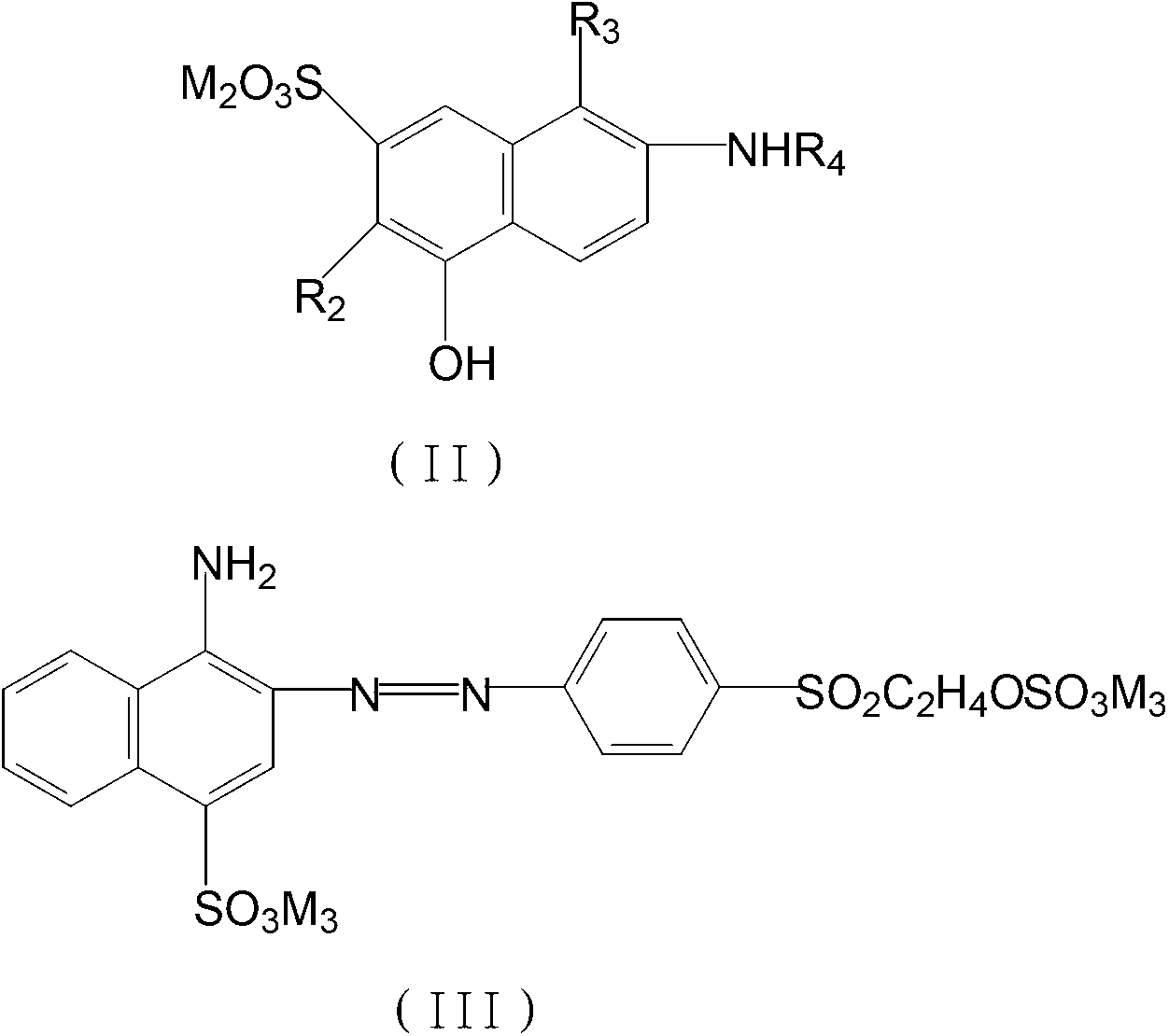

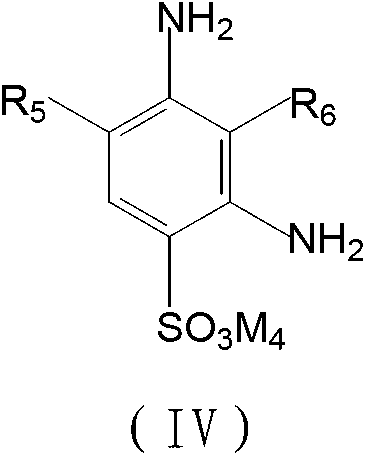

Method used

Image

Examples

preparation example 1

[0069] Weigh 30.35 g of para-ester (i.e., p-(β-sulfate ethyl sulfone) aniline) in a 500-ml beaker, add an appropriate amount of water and ice for ice grinding and beating, and add 12.72 g after half an hour. The concentration is 31 % (w / w) hydrochloric acid, and then add 30% (w / w) concentration of sodium nitrite solution (containing 7.46 g of sodium nitrite) dropwise to the para-ester solution, and control the temperature to 0-5 °C for reconditioning. Nitriding. After the para-ester diazotization is completed, a diazo liquid is obtained, and 32.86 grams of H acid are weighed and added to the above-mentioned diazo liquid, and the temperature is controlled at 5 to 10° C. The reaction is stirred for 10 hours, and then the pH is adjusted to 2 to 2.5 with baking soda to make it acidic. The coupling reaction is complete, and the acidic coupling is obtained.

[0070] Weigh 17.82 grams of anthranilic acid in a 250 ml beaker, add an appropriate amount of water and ice for ice grinding...

preparation example 2

[0075] Weigh 30.35 g of para-ester (i.e., p-(β-sulfate ethyl sulfone) aniline) in a 500-ml beaker, add an appropriate amount of water and ice for ice grinding and beating, and add liquid caustic soda after half an hour to adjust the pH to 12. Control the temperature at 0-5°C, add 12.72 grams of hydrochloric acid with a concentration of 31% (w / w) after the pH is stable for one hour, and then add a 30% (w / w) concentration of sodium nitrite solution (containing sodium nitrite). 7.46 g) was added dropwise to the para-ester solution, and the temperature was controlled at 0-5 °C for diazotization. After the para-ester diazotization is completed, a diazo liquid is obtained, and 32.86 grams of H acid are weighed and added to the above-mentioned diazo liquid, and the temperature is controlled at 5 to 10° C. The reaction is stirred for 10 hours, and then the pH is adjusted to 2 to 2.5 with baking soda to make it acidic. The coupling reaction is complete, and the acidic coupling is obtai...

preparation example 3

[0081] Weigh 29.51 g of meta-ester (i.e., m-(β-sulfate ethylsulfone) aniline) in a 500-ml beaker, add an appropriate amount of water and ice for ice grinding and beating, and add 12.36 g after half an hour. The concentration is 31 % (w / w) hydrochloric acid, and then add 30% (w / w) concentration of sodium nitrite solution (containing 7.25 g of sodium nitrite) dropwise to the meta-ester solution, and control the temperature to 0-5 °C for reconditioning. Nitriding. After the meta-ester diazo is completed, a diazo liquid is obtained, 31.9 grams of H acid are weighed and added to the above-mentioned diazo liquid, the temperature is controlled at 15 to 20 ° C and the reaction is stirred for 8 hours, and then the pH is adjusted to 3 to 3.5 to make the acid coupling reaction complete. Acid couples.

[0082] In addition, weigh 25.3 grams of aniline-2,5-disulfonic acid in a 250-ml beaker, add an appropriate amount of water and ice for ice grinding and beating, and add 5.8 grams of hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com