Hole sealing method capable of improving alkali resistance and corrosion resistance of anode oxide film of aluminum and aluminum alloy

A technology of anodic oxidation film and corrosion resistance, which is applied in the direction of electrolytic coating, surface reaction electrolytic coating, coating, etc., can solve the problems of poor reproducibility of continuous acid and alkali resistance, and improve corrosion resistance, acid resistance, The effect of strong alkali resistance

Active Publication Date: 2016-11-16

武汉风帆电化科技股份有限公司 +1

View PDF7 Cites 27 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The inventor reproduced the patent CN103469276A method to process the aluminum anodic oxide film and carried out a performance test, and found that its continuous acid and alkali resistance performance (10min pH=1+10min pH=13.5) has poor reproducibility

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

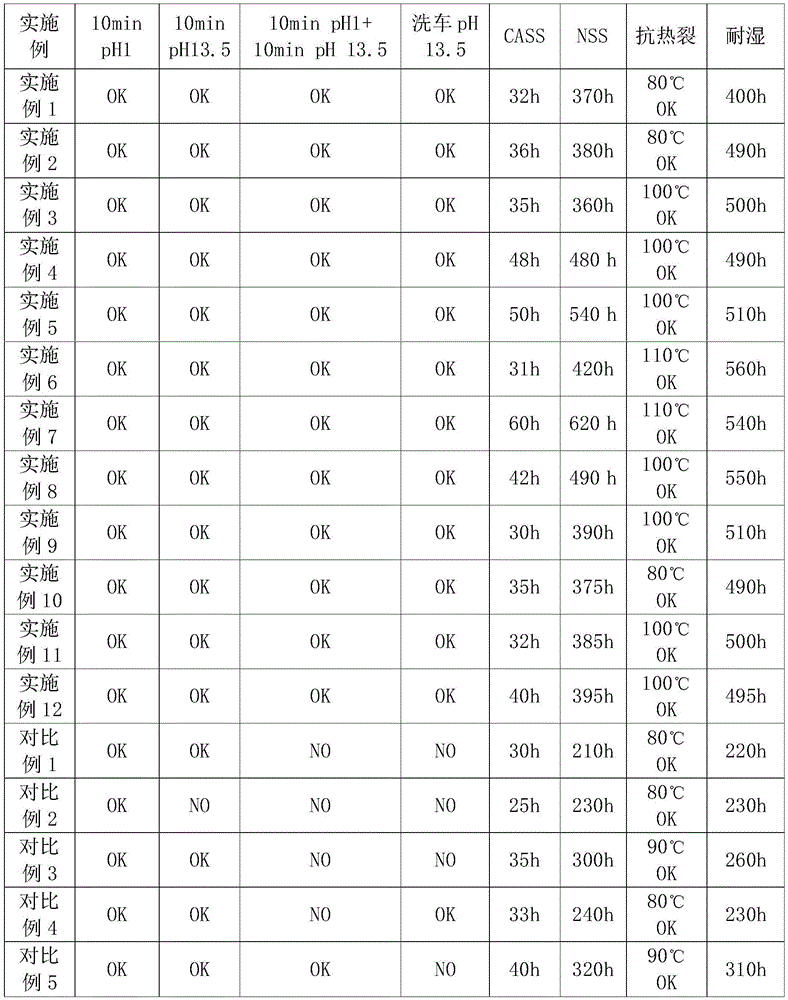

Embodiment 1

[0034] Embodiment 1: nickel fluoride cold seal+hexavalent chromium passivation+boiling water seal.

Embodiment 2

[0035] Embodiment 2: Nickel fluoride cold seal+trivalent chromium passivation+boiling water seal.

Embodiment 3

[0036] Embodiment 3: Nickel salt hot water sealing + chromium-free passivation + medium and high temperature sealing.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

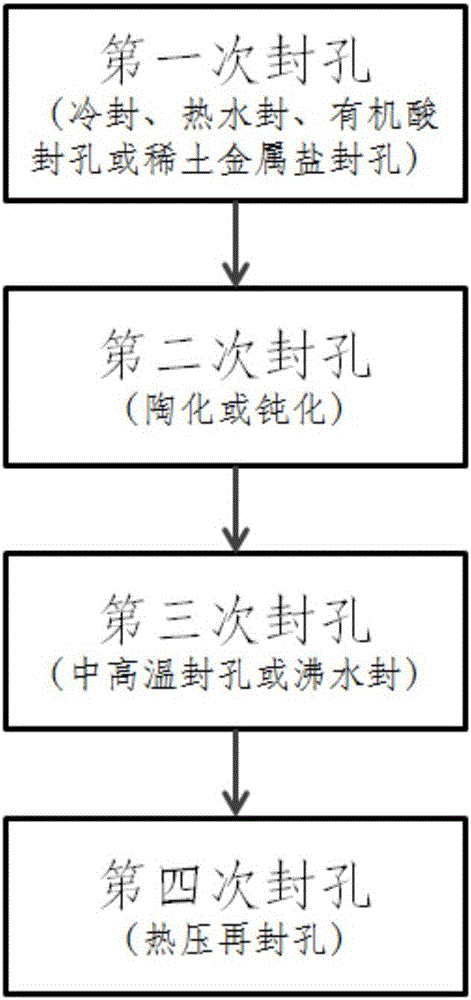

The invention belongs to the technical field of surface treatment for anodic oxidation workpieces of the automobile industry, and particularly relates to a hole sealing method capable of improving the alkali resistance and corrosion resistance of an anode oxide film of aluminum and aluminum alloy. The hole sealing method comprises the step that hole sealing treatment is carried out on an aluminum and aluminum alloy workpiece subjected to anodic oxidation treatment three times sequentially, specifically, the first time of hole sealing adopts cold sealing, hot water sealing, organic acid hole sealing or rare earth metal salt hole sealing, the second time of hole sealing adopts passivation or ceramization, and the third time of hole sealing adopts intermediate and high-temperature heat hole sealing or boiling water sealing. The hole sealing method provided by the invention breaks through the bottleneck of an existing single-step or two-step hole sealing technology; a multi-step technology is utilized, the advantages of each step of hole sealing are taken into full play, and by introducing the passivation technology for intermediate hole sealing, the corrosion resistance and continuous acid-base resistance can be remarkably improved, and higher alkaline resistance is achieved; and the passivation hole sealing mode is adopted between cold sealing and heat sealing to form a barrier layer, so that the acid resistance, alkali resistance, the continuous acid and base resistance, moisture resistance and the like of the anode oxide film are comprehensively improved.

Description

technical field [0001] The invention belongs to the technical field of surface treatment of anodized workpieces in the automobile industry, and in particular relates to a hole sealing method capable of improving the alkali resistance and corrosion resistance of aluminum and aluminum alloy anodized films. Background technique [0002] Due to the excellent physical and chemical properties of aluminum and aluminum alloys, the application of aluminum and aluminum alloys in building materials, aerospace, automobiles, mobile phones and other industries has become more and more extensive. Aluminum will form a thin layer of natural oxide film in the air. This layer of naturally formed oxide film does not have good corrosion resistance and other properties, and cannot meet the needs of practical applications. At present, the industry usually adopts the aluminum anodic oxidation process. After a series of pretreatment steps such as degreasing, polishing, alkali etching and neutralizat...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C25D11/18

CPCC25D11/18

Inventor 陆烽烽王婷劳浩鹏王茂堂

Owner 武汉风帆电化科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com