Marble paint and preparation method thereof

A technology of marble paint and quartz sand, which is applied in the field of paint and simulated paint, can solve the problems of dryness and adhesion that cannot meet the needs, and achieve excellent weather resistance, excellent decorative performance, and water-based environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

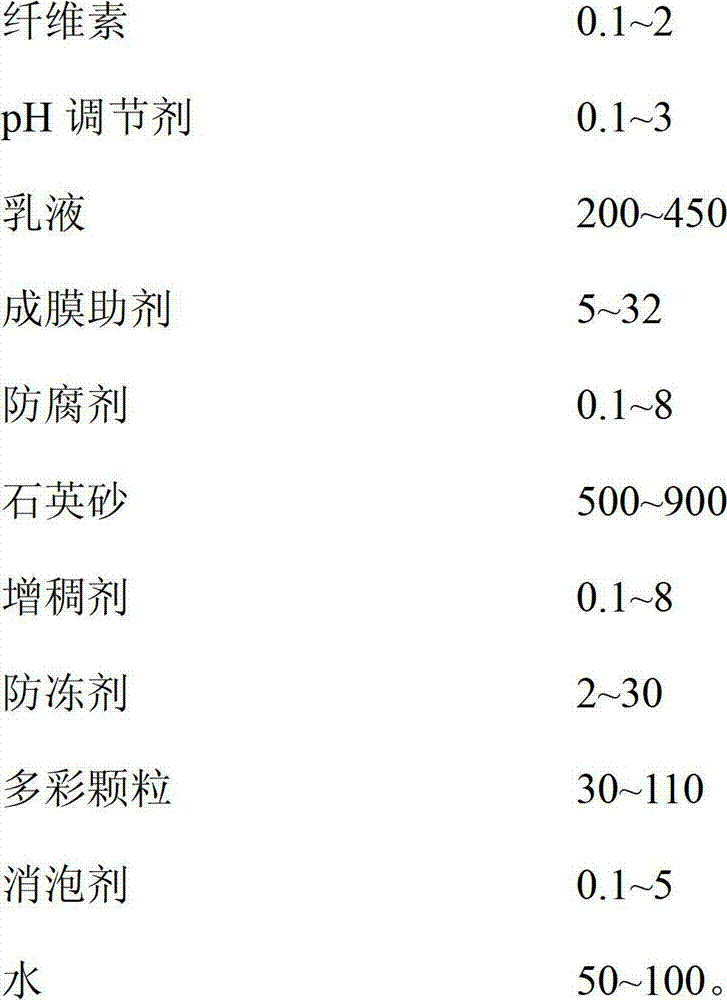

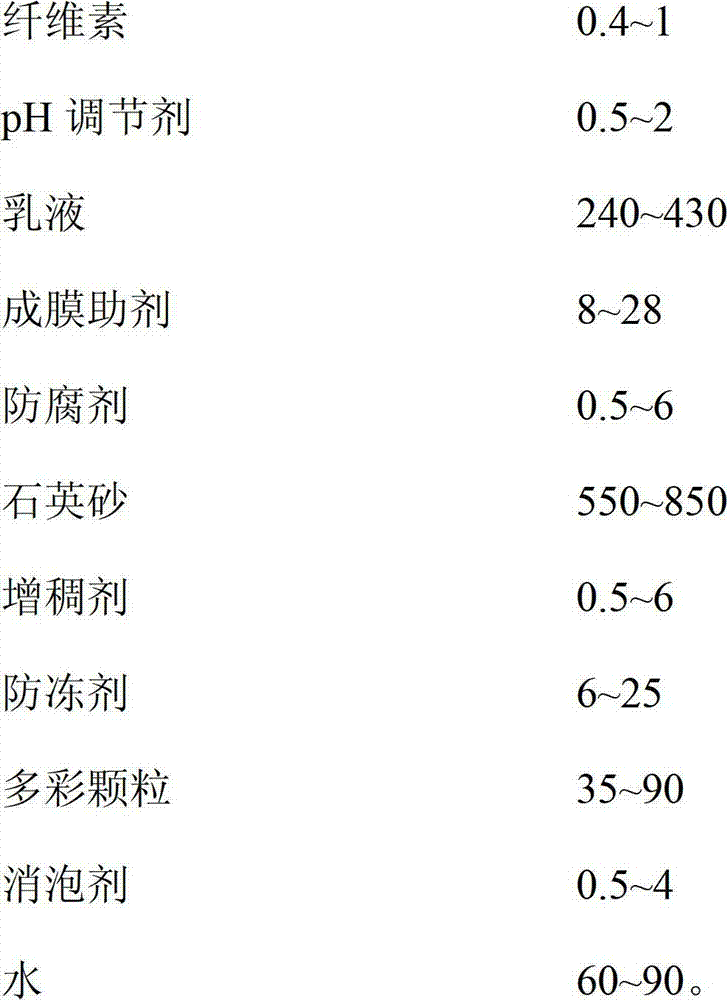

Method used

Image

Examples

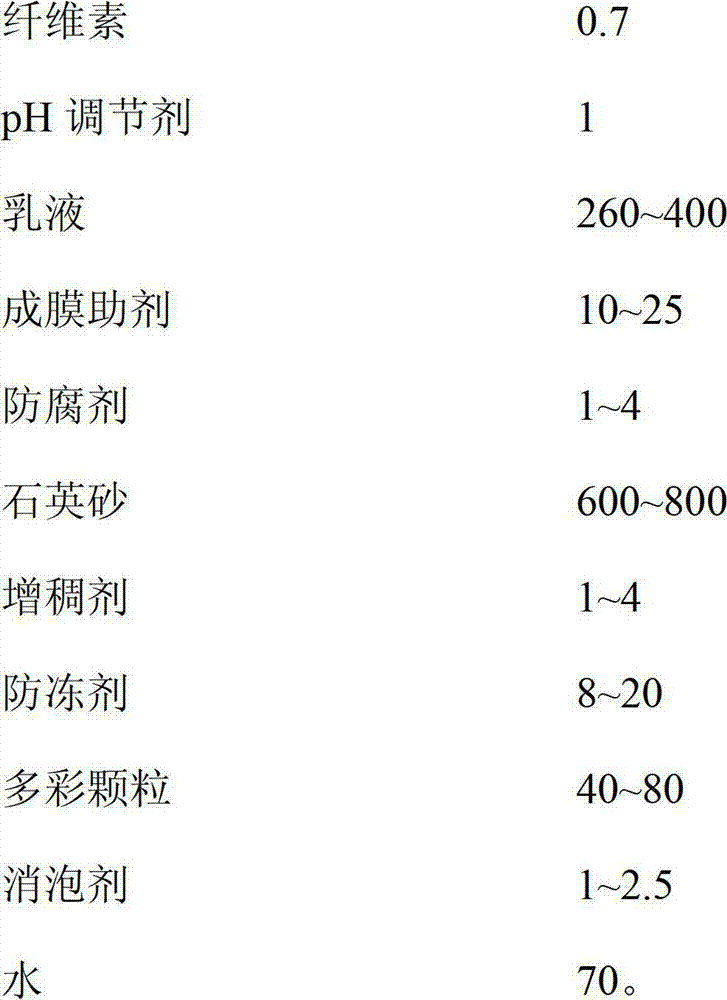

Embodiment 1

[0065] (1) Weigh 70 parts of deionized water into the reactor, then start the high-speed disperser and control the speed at 400r / min, weigh 0.7 parts of cellulose and 1 part of AMP-95 into the reactor, increase the speed to 800r / min until the dispersion is uniform , the temperature is controlled below 40 degrees;

[0066] (2) Weigh 1 part of mineral oil defoamer, 8 parts of ethylene glycol, 25 parts of alcohol ester twelve, 4 parts of preservative, reduce the speed to 600r / min, control the temperature below 40 degrees, and disperse evenly;

[0067] (3) Weigh 400 parts of silicone acrylic resin into the reaction kettle, and disperse for 10-15 minutes at a speed of 600r / min;

[0068] (4) Weigh 600 parts of 300-mesh quartz sand and put it into the kettle, increase the speed to 800r / min, and after the dispersion is even, weigh 40 parts of 280-mesh colorful sand and gravel particles into the kettle, control the temperature below 40 degrees, and disperse evenly;

[0069] (5) Weigh ...

Embodiment 2

[0071] (1) Put 50 parts of deionized water into the reactor, then start the high-speed disperser and control the speed at 500r / min, weigh 0.1 parts of hydroxypropyl methylcellulose and 3 parts of AMP-95 into the reactor, and increase the speed to 900r / min / min until the dispersion is uniform, and the temperature is controlled below 45 degrees;

[0072] (2) Weigh 0.1 part of silicone defoamer, 2 parts of propylene glycol, 32 parts of propylene glycol butyl ether, and 0.1 part of benzoic acid, reduce the speed to 500r / min, control the temperature below 45 degrees, and disperse evenly;

[0073] (3) Weigh 450 parts of styrene-acrylic resin into the reaction kettle, and disperse for 16 minutes at a speed of 700r / min;

[0074] (4) Weigh 500 parts of 150-mesh quartz sand and put it into the kettle, increase the speed to 900r / min, and after the dispersion is uniform, weigh 30 parts of 260-mesh colorful sand and gravel particles and put them into the kettle, control the temperature bel...

Embodiment 3

[0077] (1) Weigh 100 parts of deionized water into the reactor, then start the high-speed disperser to control the speed of 300r / min, weigh 2 parts of hydroxyethyl cellulose and 0.1 part of ammonia water into the reactor, increase the speed to 700r / min to disperse Uniform, the temperature is controlled below 43 degrees;

[0078] (2) Weigh 5 parts of silicone defoamer, 30 parts of propylene glycol, 5 parts of 2,2,4-trimethyl-1,3-pentanediol-monoisobutyrate, and 8 parts of Cathone preservative , the speed is reduced to 700r / min, the temperature is controlled below 43 degrees, and the dispersion is uniform;

[0079] (3) Weigh 200 parts of styrene-acrylic resin into the reaction kettle, and disperse for 10 minutes at a speed of 500r / min;

[0080] (4) Weigh 900 parts of 150-mesh quartz sand and put it into the kettle, increase the speed to 700r / min, and after the dispersion is uniform, weigh 110 parts of 280-mesh colorful sand and gravel particles and put them into the kettle, con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com