1080 m<3> blast furnace main iron runner castable

A castable and main iron channel technology, applied in the field of refractory castables, to reduce material consumption, solve the problem of iron channel spalling, and good acid resistance

Inactive Publication Date: 2012-10-31

HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

View PDF7 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, this kind of castable with brown corundum as the main component has poor thermal shock resistance, which is easy to cause thermal spalling and structural spalling, which greatly increases the frequency of repairing iron trenches and brings great hidden dangers to the stable, safe and continuous production of blast furnaces. Improve

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

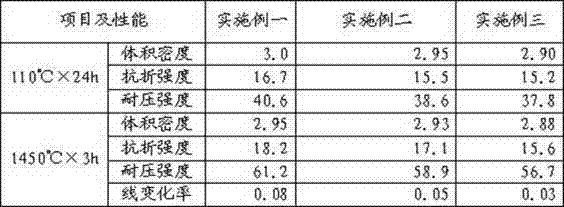

Embodiment 1

[0021] Embodiment three

Embodiment 2

[0023]

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a 1080 m<3> blast furnace main iron runner castable and belongs to the field of refractory castables. The 1080 m<3> blast furnace main iron runner castable comprises, by weight, 50-55 parts of homogenization materials, 1-8 parts of zirconium oxide hollow spheres, 3-10 parts of zirconium silicate, 10-25 parts of zinc-aluminum spinel powders, 10-15 parts of carbon compositematerials, 3-10 parts of aluminum oxide micro powders, 1-2 parts of Guangxi mud, 0.1-0.2 part of sodium tripolyphosphate, 0.05-0.2 part of metal aluminum powders and 4-10 parts of silicon dioxide solsuspension liquids. A blast furnace main iron runner prepared by the castable has the advantages of being good in thermal shock stability, anti-stripping and long in service life.

Description

technical field [0001] The present invention relates to a 1080m 3 The utility model relates to a blast furnace main iron trough castable, which belongs to the field of refractory castables. Background technique [0002] The existing main iron trough castable is ordinary Al 2 o 3 -SiC-C castables, but ordinary Al 2 o 3 -SiC-C main iron trough castables are used in blast furnaces, and the amount of one-time passing iron is 120,000 tons. With the strengthening of smelting, the demand for increasing production is becoming more and more prominent, and the requirements for the amount of iron passing through the main iron channel are becoming more and more stringent. However, due to the poor thermal shock resistance of the iron channel, it is not resistant to erosion, which leads to product peeling, which is the lifespan. The main reason for the shortness. [0003] CN102101782A discloses a castable for main iron trough, said castable is made of alumina, brown corundum, SiC, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B35/66

Inventor 山国强

Owner HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com