High-strength compress supporting agent for coarse oil and preparation method thereof

A fracturing proppant, oil technology, applied in chemical instruments and methods, earthwork drilling, production fluids, etc., can solve the problem of difficult to prepare high-strength and stable performance oil fracturing proppant, iron oxide and alkali metal oxide content high, unstable red mud composition, etc., to achieve the effects of being conducive to sustainable economic development, easy preparation methods, and good practical prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A petroleum fracturing proppant, the raw materials are as follows in mass parts: 85 parts of ceramic roller bar waste, 5 parts of red mud, 3 parts of manganese oxide, and 7 parts of ceramic clay.

[0035] 1. Add 85 parts of ceramic roller waste, 5 parts of red mud, 3 parts of manganese oxide and 7 parts of ceramic clay into the ball mill, add 0.3% of the total weight of raw materials as a ball milling aid sodium tripolyphosphate, and add water for ball milling for 6 to 8 hours , to obtain a homogeneous slurry. The solid content of the slurry is 60wt%.

[0036] 2. Dry the slurry prepared in step 1 in a spray drying tower to obtain a powder;

[0037] 3. Form the powder obtained in step 2 into a semi-finished proppant with a particle size of 30-50 mesh on a sugar-coated ball forming machine;

[0038] 4. Dry the semi-finished product obtained in step 3, and burn it in a tunnel kiln at a temperature of 1520°C to obtain a proppant for oil fracturing, with a particle size of...

Embodiment 2

[0040] 1. Add 75 parts of ceramic roller waste, 14 parts of red mud, 3 parts of barium carbonate, 1 part of dolomite and 7 parts of ceramic clay into a ball mill, add 0.3wt.% sodium tripolyphosphate, add water and ball mill for 6-8 hours, and get Uniform slurry. The solid content of the slurry is 60wt%.

[0041] 2. Dry the slurry prepared in step 1 in a spray drying tower to obtain a powder with a certain particle size;

[0042] 3. Form the powder obtained in step 2 into a semi-finished proppant with a particle size of 20-40 mesh on a sugar-coated ball forming machine;

[0043] 4. Dry the semi-finished product obtained in step 3, and burn it in a tunnel kiln at a temperature of 1430°C to obtain a proppant for oil fracturing with a particle size of 20-40 mesh.

Embodiment 3

[0045] 1. Add 60 parts of ceramic roller waste, 18 parts of red mud, 15 parts of fly ash, 1 part of dolomite and 6 parts of ceramic clay into the ball mill, add 0.3wt.% sodium tripolyphosphate, and add water for ball milling for 6-8 hours , to obtain a homogeneous slurry. The solid content of the slurry is 60wt%.

[0046] 2. Dry the slurry prepared in step 1 in a spray drying tower to obtain a powder with a certain particle size;

[0047] 3. Form the powder obtained in step 2 into a semi-finished proppant with a particle size of 20-40 mesh on a sugar-coated ball forming machine;

[0048] 4. Dry the semi-finished product obtained in step 3, and burn it in a rotary kiln at a temperature of 1350°C to obtain a proppant for oil fracturing with a particle size of 20-40 mesh.

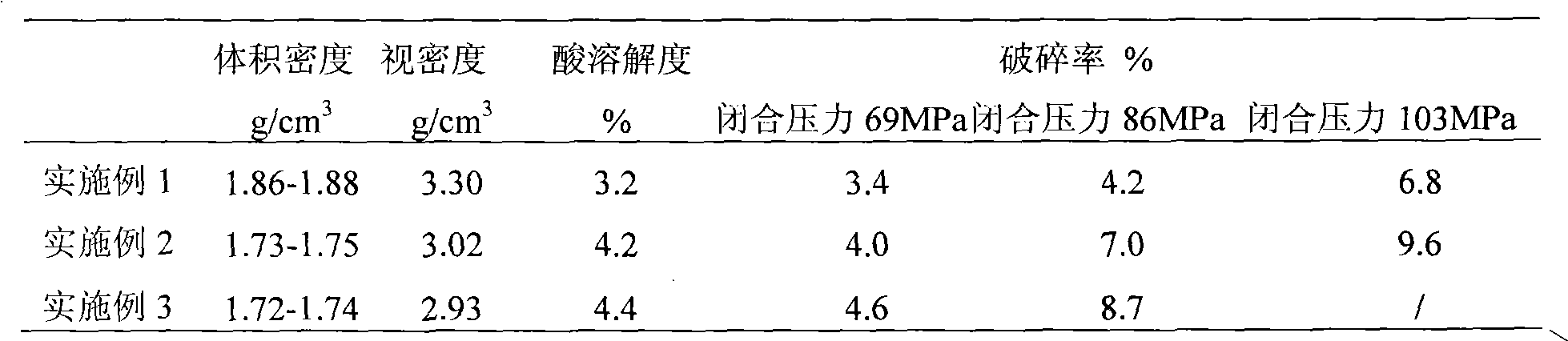

[0049] The relevant performance data of the oil fracturing proppant of the above embodiments 1-3 are as follows:

[0050]

[0051] *Tested according to SY / T5108-2006, "Recommended method for performance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com