Single-component interfacial agent and preparation method thereof

An interface agent, one-component technology, applied in the field of building construction materials, can solve the problems of hidden structural safety, low bonding strength, cracking of new and old concrete joint surfaces, etc., to overcome drying shrinkage, stable hydration reaction speed, and superior interface. The effect of bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

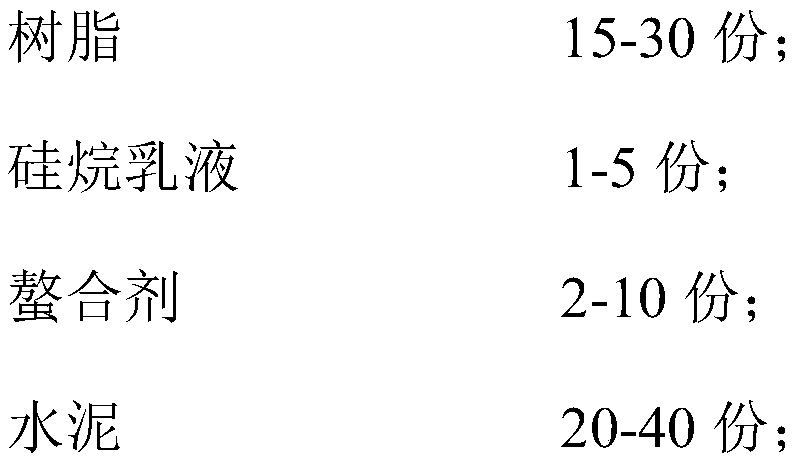

[0032] A one-component interface agent, comprising the following active ingredients in parts by weight:

[0033]

[0034] The powder of the above ingredients is mixed uniformly at room temperature in proportion to obtain the product.

Embodiment 2

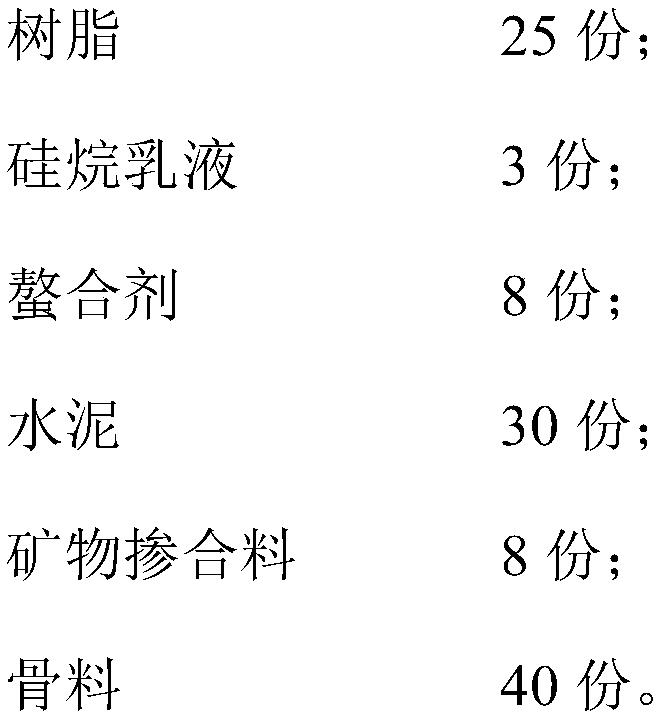

[0036] A one-component interface agent, comprising the following active ingredients in parts by weight:

[0037]

[0038] The powder of the above ingredients is mixed uniformly at room temperature in proportion to obtain the product.

Embodiment 3

[0040] A one-component interface agent, comprising the following active ingredients in parts by weight:

[0041]

[0042]

[0043] The powder of the above ingredients is mixed uniformly at room temperature in proportion to obtain the product.

[0044] Test the above one-component interface agent:

[0045] 1. The splitting tensile strength test method of "Test Methods for Mechanical Properties of Ordinary Concrete",

[0046] Use concrete strength grade:

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com