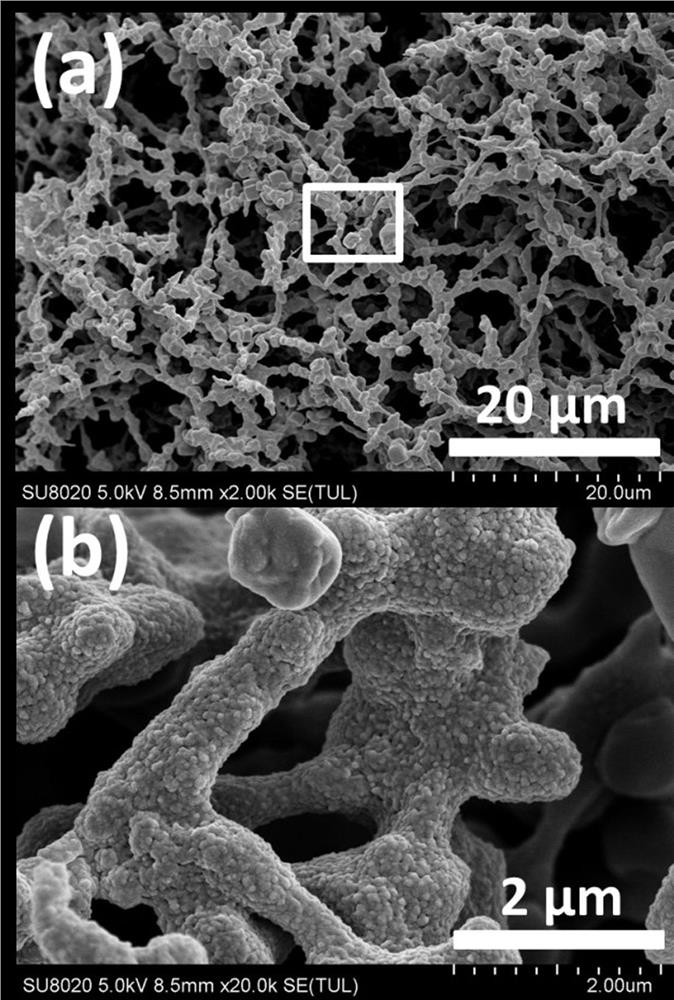

A preparation method of polyaniline/manganese dioxide electrode material with three-dimensional network structure

A manganese dioxide electrode and network structure technology, applied in the field of electrochemical energy storage, can solve the problems of short cycle life, easy expansion and contraction, poor conductivity of manganese dioxide, etc., to improve stability, overcome expansion and contraction, The effect of the simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Dissolve 1.0g of polyvinyl alcohol completely in 20mL of deionized water under heating conditions, cool naturally, and set aside. Put the prepared polyvinyl alcohol aqueous solution in an ice-water bath and stir, then add 2.07g of aniline hydrochloride, 0.05g of boric acid, and 1.27g of potassium permanganate in sequence, stir evenly, and let it stand at room temperature for a certain period of time. The reaction product is placed in a large amount of deionized water purification equilibrium to remove oligomers and inorganic substances, and the polyaniline / manganese dioxide electrode material can be obtained.

Embodiment 2

[0021] Dissolve 1.0 g of polyvinyl alcohol completely in 20 mL of deionized water at 90° C., cool naturally, and set aside for use. Put the prepared polyvinyl alcohol aqueous solution in an ice-water bath and stir, then add 1.65g of aniline hydrochloride, 0.05g of boric acid, and 1.27g of potassium permanganate in sequence, stir evenly, and let it stand at room temperature for a certain period of time. The reaction product is placed in a large amount of deionized water purification equilibrium to remove oligomers and inorganic substances, and the polyaniline / manganese dioxide electrode material can be obtained.

Embodiment 3

[0023] Dissolve 1.0 g of polyvinyl alcohol completely in 20 mL of deionized water at 90° C., cool naturally, and set aside for use. Put the prepared polyvinyl alcohol aqueous solution in an ice-water bath and stir, then add 2.07g of aniline hydrochloride, 0.05g of boric acid, 1.27g of potassium permanganate, and 1.82g of ammonium persulfate in sequence. time. The reaction product is placed in a large amount of deionized water purification equilibrium to remove oligomers and inorganic substances, and the polyaniline / manganese dioxide electrode material can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com