Reinforcing slurry for semi-rigid base and grouting method of reinforcing slurry

A semi-rigid base, grouting technology, applied in buildings, roads, roads, etc., can solve the problems of difficult to grasp the grouting amount, road uplift and uplift, and delay in opening traffic, so as to shorten the traffic closure time and avoid excessive expansion rate. Large, enhance the effect of carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

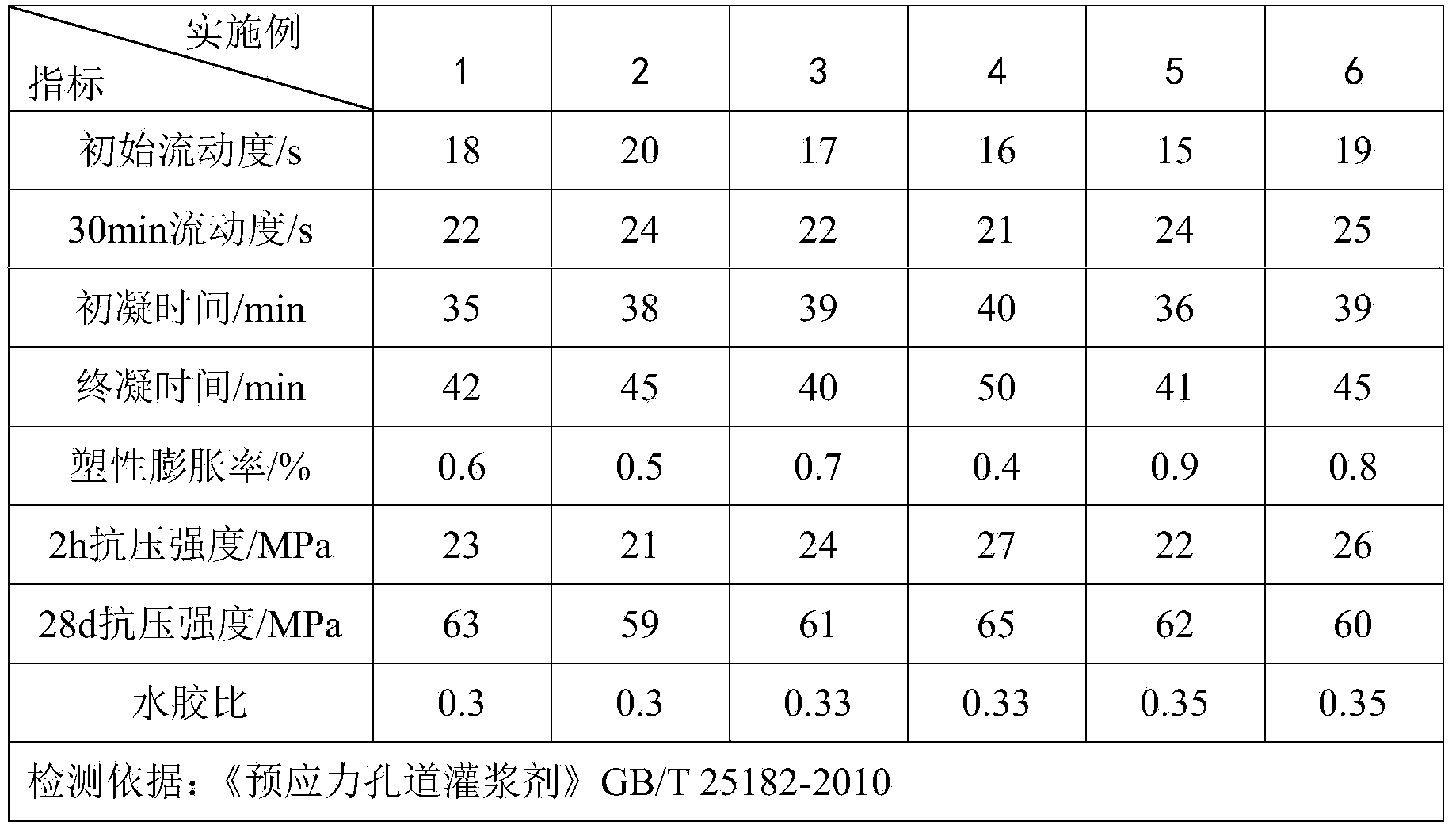

[0033] Embodiment 1: Prepare a kind of semi-rigid base layer reinforcement grout of the present invention, take by mass ratio: sulfoaluminate cement 99.6%; Powdered polycarboxylate superplasticizer 0.09%; Boric acid 0.24%; Lithium carbonate 0.04%; Azodicarbonamide 0.03%; no mineral fillers; mix the above raw materials uniformly by mechanical stirring to obtain a semi-rigid base layer reinforcement grout. During on-site construction, use a pulping machine with a rotating speed of 700r / min, and the mass ratio of water to grouting material is 0.3. Add water first and then add slurry. After adding all the powder, stir for 3 minutes to make slurry.

Embodiment 2

[0034] Embodiment 2: prepare a kind of semi-rigid base layer reinforcement grout of the present invention, take by mass ratio: sulfoaluminate cement 95.6%; Powdered polycarboxylate superplasticizer 0.08%; Tartaric acid 0.25%; Lithium hydroxide 0.02% and lithium carbonate 0.02%; plastic expansion agent adopts azodicarbonamide 0.02% and azobisisoheptanonitrile 0.01%; microbead powder 4%; the raw materials of the above ratio are mixed by mechanical stirring A semi-rigid base reinforcement grout is uniformly obtained. During on-site construction, use a pulping machine with a rotating speed of 550r / min, and the mass ratio of water to grouting material is 0.3. Add water first and then add slurry. After adding all the powder, stir for 5 minutes to make a slurry.

Embodiment 3

[0035] Embodiment 3: Prepare a kind of semi-rigid base layer reinforcement grout of the present invention, take by mass ratio: sulfoaluminate cement 96%; Powdered naphthalene series superplasticizer 0.68%; Tartaric acid 0.1% and boric acid 0.15%; Hydrogen 0.01% of lithium oxide and 0.02% of lithium chloride; 0.02% of azobisisobutyronitrile and 0.02% of azobisisoheptanonitrile; 3% of slag powder; the raw materials of the above ratio are mixed uniformly by mechanical stirring to obtain a Semi-rigid base reinforcement grout. During on-site construction, use a pulping machine with a rotational speed of 650r / min, and the mass ratio of water to grouting material is 0.33. Add water first and then inject slurry. After adding all the powder, stir for 3 minutes to make slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| curing time | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com