Drag reducer and preparation method thereof

A technology of drag reducing agent and isolating agent, applied in mechanical equipment, pipeline systems, gas/liquid distribution and storage, etc., can solve problems such as affecting the normal transportation of crude oil, loss of light oil content, etc., and achieve stable drag-reducing polymer particle suspension. system, the effect of slowing down agglomeration and preventing particles from sticking to each other

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This example is used to illustrate the preparation method of SME release agent.

[0035] Add 9.8g of maleic anhydride and 100mL of toluene into a three-necked flask, raise the temperature to reflux temperature to dissolve the maleic anhydride, cool down to 80°C, add 0.24g of dodecanethiol and 10.3g of styrene, keep the reaction temperature at 80°C, and dissolve the peroxide Dissolve 0.24g of benzoyl (BPO) in 30mL of toluene, slowly add it dropwise into a three-neck flask, keep it warm for 4 hours, during which the copolymer of styrene-maleic anhydride is continuously precipitated, filter, and put the filter cake at 80°C Vacuum drying yielded 17.2 g of styrene-maleic anhydride copolymer.

[0036] Take 17.2 g of the above styrene-maleic anhydride copolymer, add 43 g of stearyl alcohol, 100 mL of toluene, and 0.5 g of p-toluenesulfonic acid, raise the temperature to reflux temperature, and react for 4 hours, during which the styrene maleic anhydride solid gradually dissolv...

Embodiment 2

[0038] This example is used to illustrate the preparation method of polyalphaolefin / simethicone oil slurry.

[0039] The polymerization catalyst used is prepared according to the following method: add 2.0 grams of ethoxymagnesium particle carrier (particle diameter is 40-50 microns), toluene 30ml into the reaction bottle and disperse evenly, lower the temperature to -10°C, add 10ml (6.0mol )TiCl4, stay for 0.5 hours, heat up to 80°C, add 0.6ml (0.39mol) diisobutyl phthalate, heat up to 110°C, react for 2 hours, settle, filter, wash with toluene twice (20ml each time), Secondary titanium loading, adding 5ml (3.0mmol) TiCl4 and 30ml toluene to react for 1 hour, settling, filtering, washing with hexane four times, and drying at 72°C to obtain the catalyst solid component. The mass percent content of titanium in the catalyst is 2.87%.

[0040] Mix 35g of 1-octene refined by molecular sieves (purchased from ACROS Reagent Company) with 65g of dimethicone oil refined by molecular si...

Embodiment 3

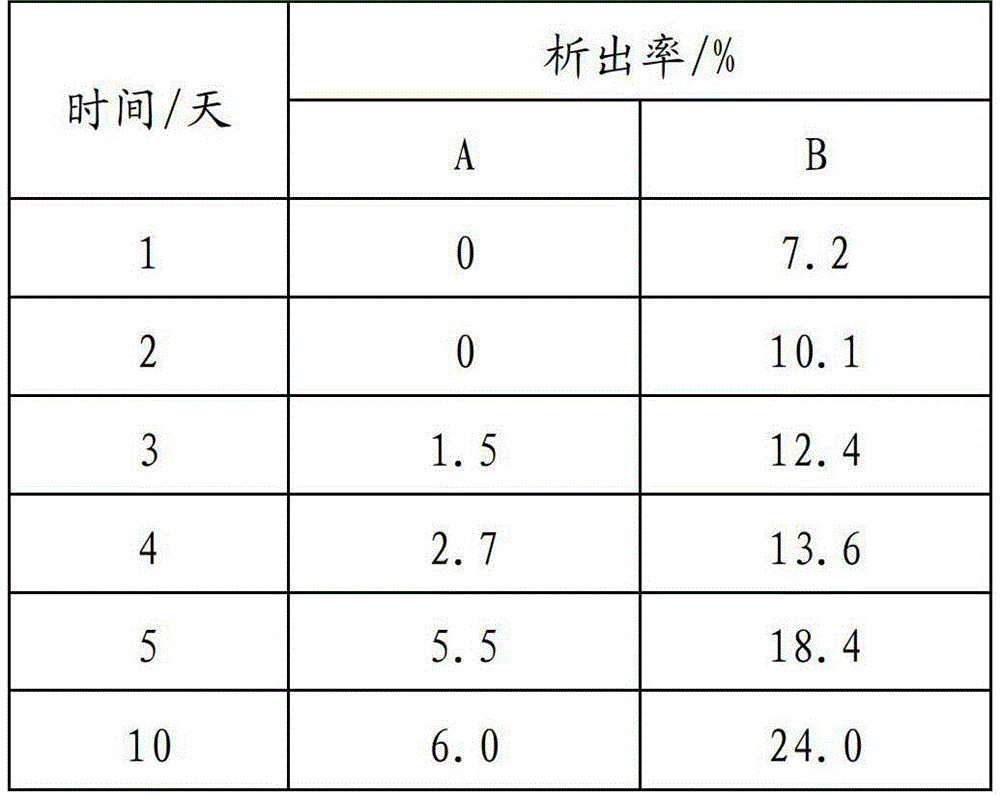

[0042] Prepare polyalpha-olefin / dimethyl silicone oil slurry by the same method as in Example 2. After the polymerization reaction, add 9 g of SME to the slurry, stir for 30 minutes, add 2 g of sodium petroleum sulfonate, and stir for 30 minutes to obtain drag reducer slurry A. See Table 1 for storage stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com