Production method of antibacterial stainless steel drainer drawn piece

A technology of antibacterial stainless steel and production method, which is applied in water supply equipment, indoor sanitary pipeline installations, buildings, etc. It can solve the problems of affecting the processing performance of stainless steel, unstable antibacterial performance, and loss of antibacterial ability, and achieves a smooth surface without orange peel. The effect of low price and excellent antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

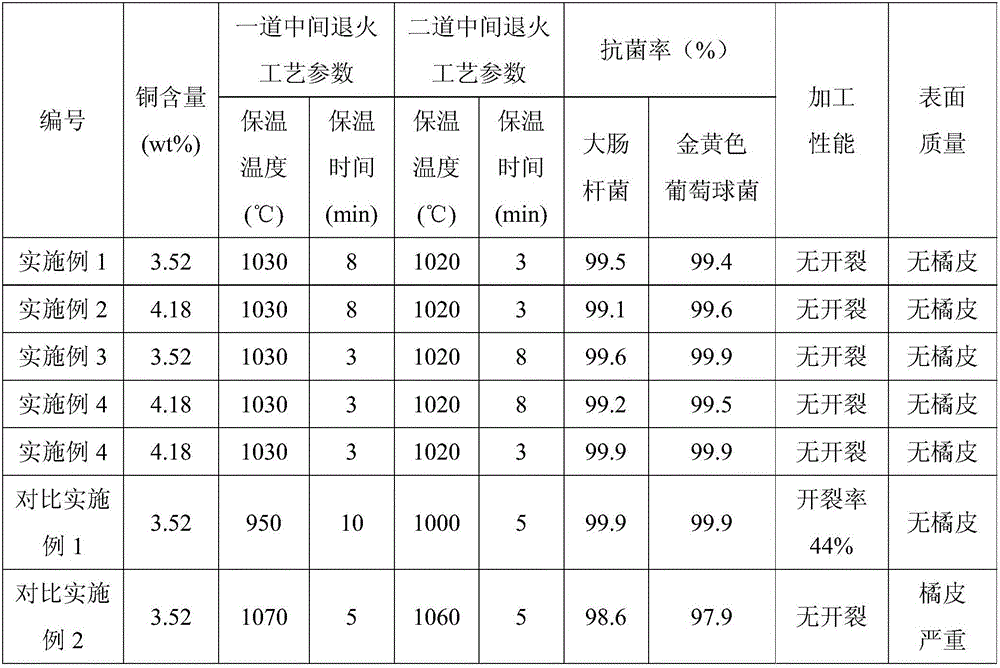

Embodiment 1

[0029] Using austenitic antibacterial stainless steel as raw material (Cu=3.52wt.%, C≤0.08wt%, Si≤1.0wt%, Mn≤2.0wt%, P≤0.045wt%, S≤0.03wt%, Ni=8~ 10.5wt%, Cr=17~19wt%, and the balance is Fe) to make the sewer tensile parts. The process parameters of an intermediate annealing are: the atmosphere is an ammonia protective atmosphere, the holding temperature is 1030°C, the holding time is 8 minutes, and the cooling method is air cooling. The process parameters of the two intermediate annealing are: the atmosphere is an ammonia protective atmosphere, the holding temperature is 1020°C, and the holding time is 3 minutes. The surface of the prepared antibacterial drainer is smooth and flat without cellulite, and the killing rates of Escherichia coli and Staphylococcus aureus are all above 99%.

Embodiment 2

[0031] Using austenitic antibacterial stainless steel as raw material (copper 4.18wt%, C≤0.08wt%, Si≤1.0wt%, Mn≤2.0wt%, P≤0.045wt%, S≤0.03wt%, Ni=8~10.5 wt%, Cr=17~19wt%, and the balance is Fe) to make the sewer tensile parts. The process parameters of an intermediate annealing are: the atmosphere is an ammonia protective atmosphere, the holding temperature is 1030°C, the holding time is 8 minutes, and the cooling method is air cooling. The process parameters of the two intermediate annealing are: the atmosphere is an ammonia protective atmosphere, the holding temperature is 1020°C, and the holding time is 3 minutes. The surface of the prepared antibacterial drainer is smooth and flat without cellulite, and the killing rates of Escherichia coli and Staphylococcus aureus are all above 99%.

Embodiment 3

[0033] Use austenitic antibacterial stainless steel as raw material (copper 3.52wt%, C≤0.08wt%, Si≤1.0wt%, Mn≤2.0wt%, P≤0.045wt%, S≤0.03wt%, Ni=8~10.5 wt%, Cr=17~19wt%, and the balance is Fe) to make the sewer tensile parts. The process parameters of an intermediate annealing are: the atmosphere is an ammonia protective atmosphere, the holding temperature is 1030°C, the holding time is 3 minutes, and the cooling method is air cooling. The process parameters of the two intermediate annealing are: the atmosphere is an ammonia protective atmosphere, the holding temperature is 1020°C, and the holding time is 8 minutes. The surface of the prepared antibacterial drainer is smooth and flat without cellulite, and the killing rates of Escherichia coli and Staphylococcus aureus are all above 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com