Silicone opening slipping agent master batch composition for plastic film and preparation method of silicone opening slipping agent master batch

A plastic film and slip agent technology, which is applied in the field of anti-opening agent, can solve the problems affecting film transparency, irregular particle shape, and affecting film appearance, so as to avoid the impact of processing performance, reduce friction coefficient, and good opening smooth effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

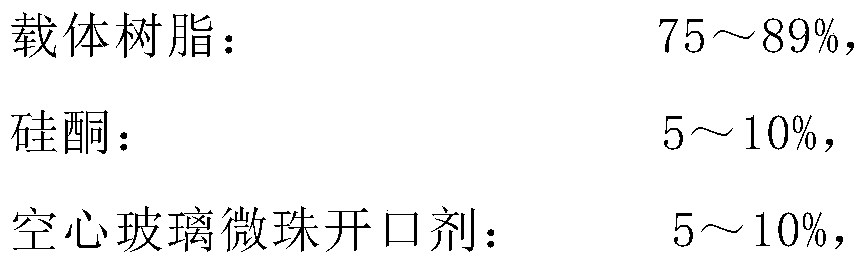

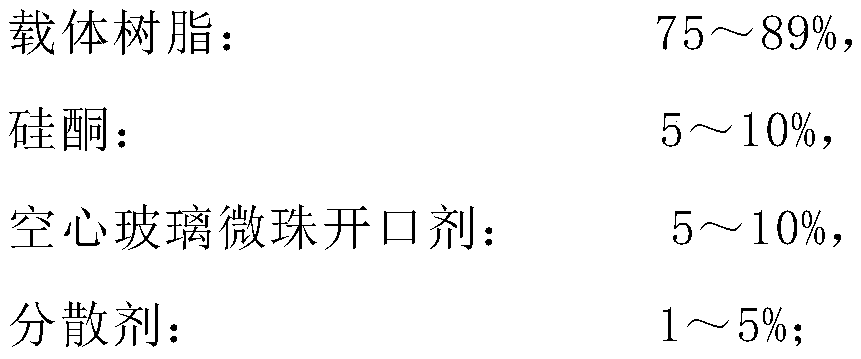

[0027] This embodiment relates to a preparation method of a silicone opening slip agent masterbatch composition for plastic films, which specifically includes the following steps:

[0028] 1. According to the weight percentage of each component, 88% of linear low-density polyethylene with a melt index of 2g / 10min, 5% of silicone powder, 5% of hollow glass microspheres, and 2% of polyethylene wax with a number average molecular weight of 3000 Ingredients;

[0029] 2. Add the above-mentioned linear low-density polyethylene, silicone powder, hollow glass microspheres, and polyethylene wax into the high-speed mixer, first stir at low speed for 3 minutes, then stir at high speed for 1 minute, and then send it into the twin-screw extruder for melt blending , extruding, cooling, drying, and pelletizing to obtain the masterbatch composition of the opening slip agent. Among them, the temperature of each zone of the twin-screw extruder is: from the feed section to the head: 120°C, 140°...

Embodiment 2

[0031] This embodiment relates to a preparation method of a plastic film silicone opening slip agent masterbatch composition, which specifically includes the following steps:

[0032] 1. According to the weight percentage of each component, it is 81% of linear low density polyethylene with a melt index of 10g / 10min, 8% of silicone powder, 8% of hollow glass microspheres, and 3% of polyethylene wax with a number average molecular weight of 3000 Ingredients;

[0033] 2. Add linear low-density polyethylene, silicone powder, hollow glass microspheres, and polyethylene wax into a high-speed mixer, first stir at a low speed for 3 minutes, then stir at a high speed for 1 minute, and then send them into a twin-screw extruder for melt blending, Extruding, cooling, drying, and pelletizing to obtain the composition of the opening slip agent masterbatch. The temperature of each zone of the twin-screw extruder is: from the feed section to the head: 125°C, 140°C, 155°C, 165°C, 165°C, 170°C...

Embodiment 3

[0035] This embodiment relates to a preparation method of a plastic film silicone opening slip agent masterbatch composition, which specifically includes the following steps:

[0036] 1. According to the weight percentage of each component, it is 75% of linear low density polyethylene with a melt index of 20g / 10min, 10% of silicone powder, 10% of hollow glass microspheres, and 5% of polyethylene wax with a number average molecular weight of 3000 Ingredients;

[0037] 2. Add linear low-density polyethylene, silicone powder, hollow glass microspheres, and polyethylene wax into a high-speed mixer, first stir at a low speed for 3 minutes, then stir at a high speed for 1 minute, and then send them into a twin-screw extruder for melt blending, Extruding, cooling, drying, and pelletizing to obtain the composition of the opening slip agent masterbatch. The temperature of each zone of the twin-screw extruder is: from the feed section to the head: 120°C, 145°C, 155°C, 155°C, 165°C, 170...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com