Water-based antimicrobial moldproof hydrophilic paint for heat exchanger fin surface treatment

A surface treatment and heat exchanger technology, applied in antifouling/underwater coatings, polyether coatings, coatings, etc., can solve problems such as loss, difficulty in maintenance, and discoloration, and achieve less addition, good stability, and cost-effective high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

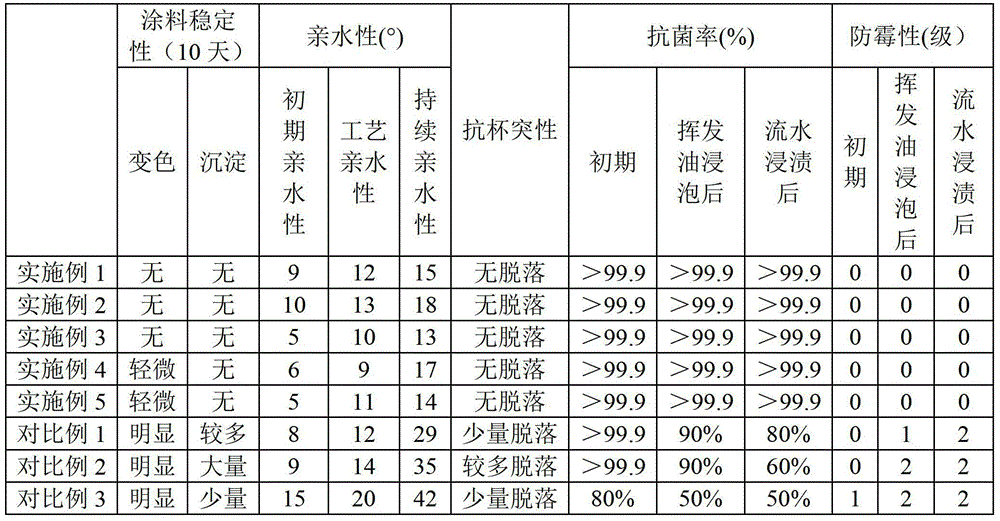

Examples

Embodiment 1

[0063] A water-based antibacterial, mildew-proof and hydrophilic coating for the surface treatment of heat exchanger fins, which consists of the following components in mass percentage: polyacrylic acid (molecular weight: 200,000) 5g, silver-loaded nano-silica 0.1g, pentaerythritol 5g, Alkylphenol polyoxyethylene ether 0.02g, ethanol 5g, and water to make up to 100g.

[0064] (1) Polyacrylic acid is prepared by the following steps:

[0065] 1. 1g of sodium persulfate is prepared into an aqueous solution of sodium persulfate with a concentration of 3% by mass;

[0066] ②Put 5g of acrylic acid and 61.7g of water into the reaction kettle, stir evenly, heat to 80°C, add the sodium persulfate aqueous solution prepared in step ① dropwise, the dropwise addition time is 30 minutes, react for 4 hours, and pass nitrogen during the whole process;

[0067] ③Reduce the temperature to 25°C to obtain polyacrylic acid (molecular weight measured by gel permeation chromatography is 200,000). ...

Embodiment 2

[0077] A water-based antibacterial, anti-mildew, and hydrophilic coating for the surface treatment of heat exchanger fins, which consists of the following ingredients in terms of mass percentage: polyacrylic acid (molecular weight: 100,000) 8g, silver-loaded nano-alumina 0.5g, glycerin 2g, alkane Base phenol polyoxyethylene ether sodium sulfate 0.02g, isopropanol 2g, and water to make up to 100g.

[0078] (1) Polyacrylic acid is prepared by the following steps:

[0079] ① 0.5g of azobisisobutyridine hydrochloride is prepared into an aqueous solution with a concentration of 5% by mass;

[0080] ②Put 10g of acrylic acid and 80g of water into the reaction kettle, stir evenly, heat to 70°C, add the aqueous solution prepared in step ① dropwise, the dropwise addition time is 30 minutes, react for 5 hours, and pass nitrogen during the whole process;

[0081] ③Reduce the temperature to 25°C to obtain polyacrylic acid (the molecular weight measured by gel permeation chromatography is ...

Embodiment 3

[0091] A water-based antibacterial, mildew-proof and hydrophilic coating for the surface treatment of heat exchanger fins, which consists of the following ingredients in mass percentage: polyethylene glycol (PEG-8000, Dow Chemical) 15g, silver-loaded nano-zirconia 0.05g, 0.3g of trimethylolpropane, 0.2g of alkyl diphenyl ether disulfonate, 10g of propylene glycol methyl ether, make up to 100g with water.

[0092] (1) Silver-loaded nano-zirconia is prepared by the following steps:

[0093] ① Prepare 5g of nano-zirconia (average particle size of 25nm, sol state) into a nano-zirconia aqueous dispersion with a concentration of 20% by mass;

[0094] ②Add 0.5g AgClO 4 Prepare AgClO with a molar concentration of 0.2mol / L 4 aqueous solution;

[0095] ③ 0.3g ascorbic acid is mixed with molar concentration and is the ascorbic acid aqueous solution of 0.3mol / L;

[0096] 4. Add the nano-zirconia aqueous dispersion liquid prepared in step 1. to the AgClO prepared in step 2. under the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com