Fault handling method of food processor

A fault handling method and technology for food processing machines, which are applied to household appliances, applications, kitchen utensils, etc., can solve the problems that the alarm cannot be restored, consumers have a bad experience, and cannot be used again, so as to avoid food waste without affecting Food processing performance and the effect of improving user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

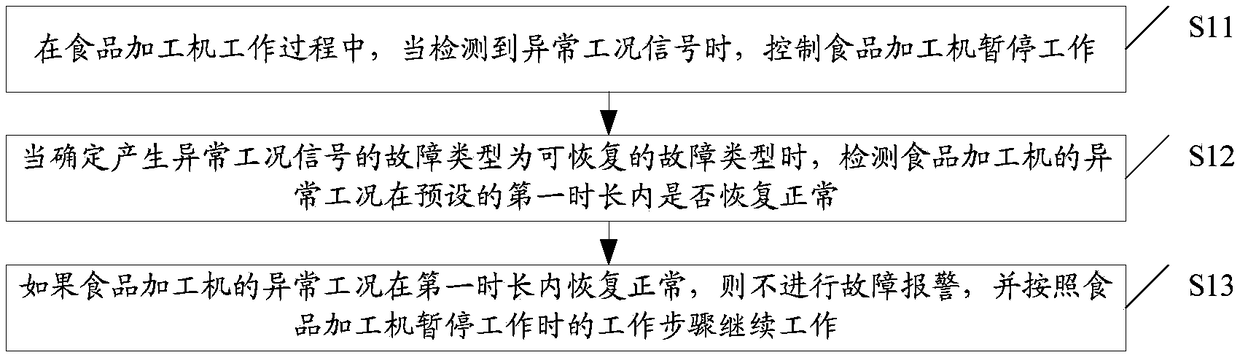

[0040] A method for troubleshooting a food processor, such as figure 1 As shown, the method may include S11-S13:

[0041] S11. During the working process of the food processing machine, when an abnormal working condition signal is detected, the food processing machine is controlled to suspend work.

[0042] In the embodiment of the present invention, some abnormal working conditions may occur due to various reasons during the working process of the food processing machine. In order to be able to respond to the abnormal working conditions in the first time, real-time detection of Abnormal working condition signal, and when the abnormal working condition signal is detected, the food processing machine is controlled to suspend work, so as to ensure the food processing performance and achieve the effect of safety protection for the food processing machine.

[0043] In the embodiment of the present invention, among the fault types that cause abnormal working conditions, if some ab...

Embodiment 2

[0066] On the basis of the first embodiment, this embodiment provides a solution when recoverable faults occur multiple times in succession.

[0067] Optionally, the method may further include: whenever the fault type is a recoverable fault type, and the abnormal working condition of the food processing machine returns to normal within the first time period, accumulatively recording the abnormal working condition once; In the second period of time, when the total number of accumulated and recorded abnormal working conditions reaches the preset number threshold, when the fault type is a recoverable fault type again, and the abnormal working condition of the food processor returns to normal within the first period of time When the situation occurs, a fault alarm will be issued.

[0068] In the embodiment of the present invention, after the abnormal working condition occurs, if it returns to normal within the first period of time, the abnormal working condition can be recorded as...

Embodiment 3

[0072] On the basis of the first or second embodiment, this embodiment provides a specific implementation plan for continuing to work after the abnormal working condition returns to normal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com