Boring cutter

A kind of boring tool and tool holder technology, which is applied to the boring tool field for milling machine boring, can solve the problems such as the equipment cannot complete the processing task and exceeds the processing range, and achieves the effect of small investment, wide processing range and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

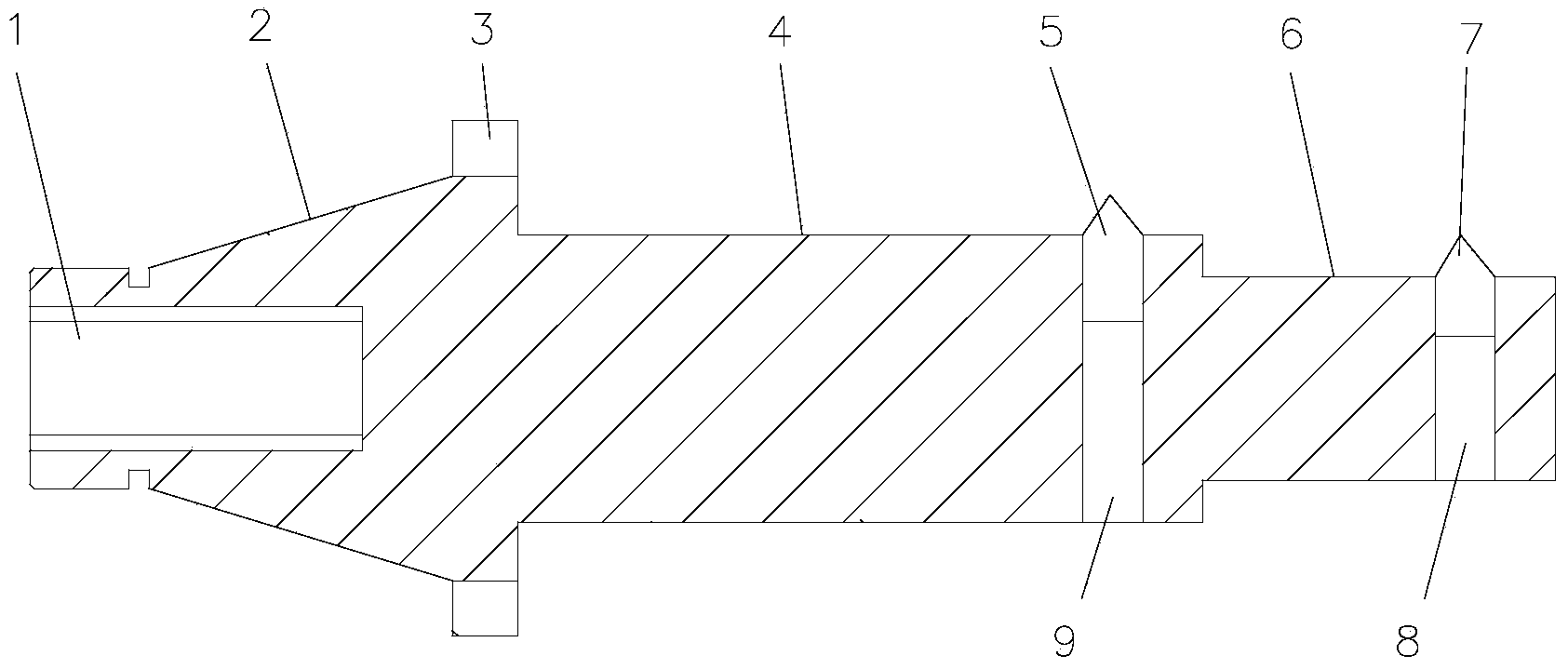

[0009] Such as figure 1 Shown, the present invention comprises cutter bar and cutting tool, and the left end of cutter bar is cone 2, and cone 2 cooperates with the cone of boring machine main shaft hole, and the axle center of cone 2 has internally threaded hole 1, and the connecting rod of boring machine main shaft Through the metric thread connection, the tension effect is played. The right end of the tool bar is the shoulder shaft 4, 6, and the right end of the shoulder shaft 4, 6 has radial left and right tool fixing holes 9, 8 respectively, and the left and right tool fixing holes 9, Fix the left and right boring cutters 5,7 respectively in 8.

[0010] The junction of the cone 2 and the shoulder shafts 4, 6 has a groove 3 with a larger diameter than the large end of the cone 2, and the groove 3 cooperates with the protrusion of the boring machine to form a rigid connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com