Organic silicon rubber

A technology of silicone rubber and fluorosilicone rubber, which is applied in the field of rubber, can solve the problem that the comprehensive performance of silicone rubber cannot meet the requirements of harsh environments, and achieve the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

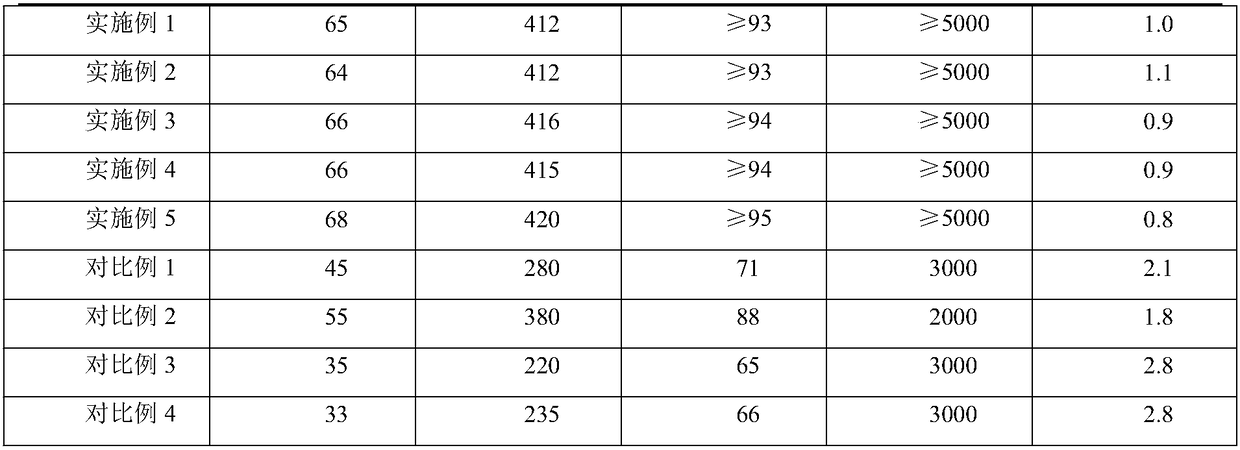

Examples

Embodiment 1

[0028] An organosilicon rubber is prepared through the following steps:

[0029] (1) Low-phenyl silicone rubber, fluorosilicone rubber modified by sucrose polyester, structure control agent and organic modified silicon powder are mixed with a kneader to obtain a mixture;

[0030] (2) Add vulcanizing agent and 2,4-pentadienoate zinc salt to the mixture, mix well and treat at 140°C for 2 hours, then heat it under vacuum for 25 minutes, cool to room temperature (25°C) and discharge it to obtain Rubber compound

[0031] (3) After cutting and compression molding the rubber mixture, use a hot press at 200°C and 15MPa for 10 minutes to obtain a shaped vulcanized product;

[0032] (4) Put the shaped vulcanized product in an oven and place it at 250°C for 10 hours, and it will be obtained.

[0033] Among them, the mass ratio of low phenyl silicone rubber, sucrose polyester modified fluorosilicone rubber, structure control agent, organic modified silicon powder, vulcanizing agent and zinc salt o...

Embodiment 2

[0041] An organosilicon rubber is prepared through the following steps:

[0042] (1) Low-phenyl silicone rubber, fluorosilicone rubber modified by sucrose polyester, structure control agent and organic modified silicon powder are mixed with a kneader to obtain a mixture;

[0043] (2) Add vulcanizing agent and zinc salt of 2,4-pentadienoate to the mixture, mix well and treat at 180°C for 3 hours, then heat it under vacuum for 40 minutes, cool to room temperature (25°C), and discharge it. Rubber compound

[0044] (3) After cutting and compression molding the rubber mixture, use a hot press at 220°C and 20MPa for 15 minutes to obtain a shaped vulcanized product;

[0045] (4) Place the shaped vulcanized product in an oven and place it at 300°C for 12 hours, and it is ready.

[0046] Among them, the mass ratio of low phenyl silicone rubber, sucrose polyester modified fluorosilicone rubber, structure control agent, organic modified silicon powder, vulcanizing agent and zinc salt of 2,4-penta...

Embodiment 3

[0054] An organosilicon rubber is prepared through the following steps:

[0055] (1) Low-phenyl silicone rubber, fluorosilicone rubber modified by sucrose polyester, structure control agent and organic modified silicon powder are mixed with a kneader to obtain a mixture;

[0056] (2) Add vulcanizing agent and zinc salt of 2,4-pentadienoate to the mixture, mix well and treat at 140°C for 3 hours, then heat it under vacuum for 25 minutes, cool to room temperature (25°C), and discharge. Rubber compound

[0057] (3) After the rubber mixture is cut and compression molded, it is hot-pressed with a hot press at 220°C and 15MPa for 15 minutes to obtain a shaped vulcanized product;

[0058] (4) Put the shaped vulcanized product in an oven and place it at 250°C for 12 hours to get it.

[0059] Among them, the mass ratio of low phenyl silicone rubber, sucrose polyester modified fluorosilicone rubber, structure control agent, organic modified silicon powder, vulcanizing agent and zinc salt of 2,4-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com