High-temperature/pressure-resistant vapor-resistant fluororubber compounded rubber

A fluororubber raw rubber and fluororubber technology, which is applied in the field of organic polymer compounds, can solve the problems of not proposing water vapor resistance, not fundamentally changing the high temperature and high pressure resistance of fluororubber, and not developing fluororubber compound rubber. , to achieve the effect of improving water vapor resistance, improving resistance to other chemical media, and excellent chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

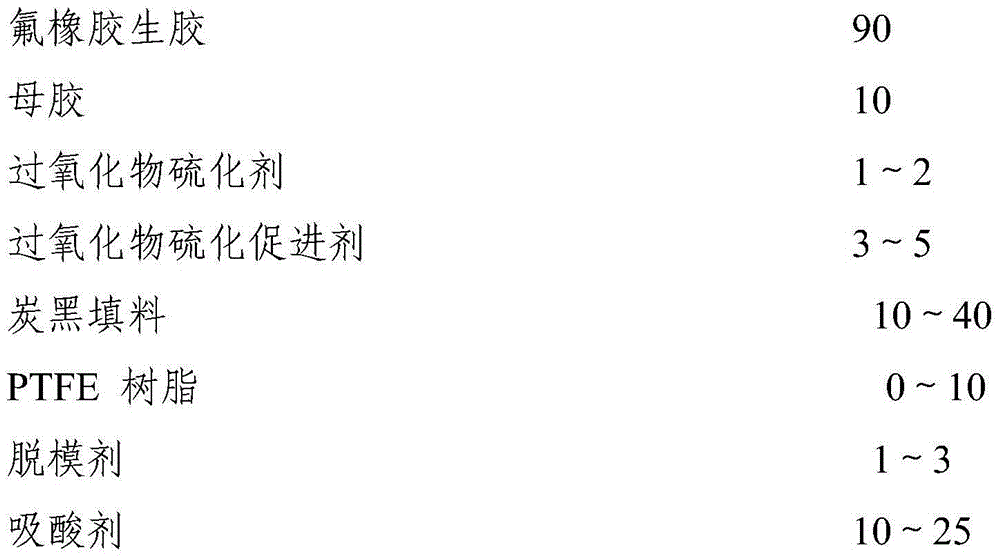

[0048] The formulation of the fluororubber compound with improved high temperature and high pressure water vapor resistance is as follows.

[0049]

Embodiment 2

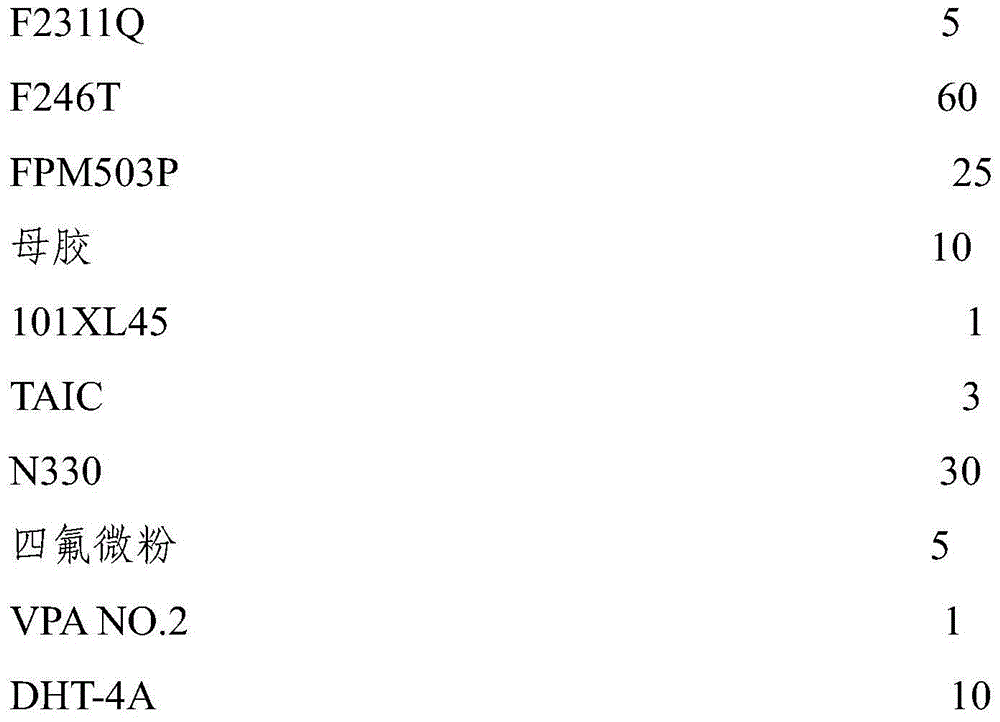

[0051] The formulation of the fluororubber compound with improved high temperature and high pressure water vapor resistance is as follows.

[0052]

[0053]

Embodiment 3

[0055] The formulation of the fluororubber compound with improved high temperature and high pressure water vapor resistance is as follows.

[0056]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com