Transparent permanent antistatic transparent polyvinylidene fluoride composition and preparation method thereof

A polyvinylidene fluoride and antistatic technology, which is applied in the field of permanent antistatic transparent polyvinylidene fluoride composition and its preparation, can solve the problems of large influence on mechanical properties and optical transparency, large addition amount, etc., and is convenient for automation The effect of controlling, adding metering convenience, and reducing processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

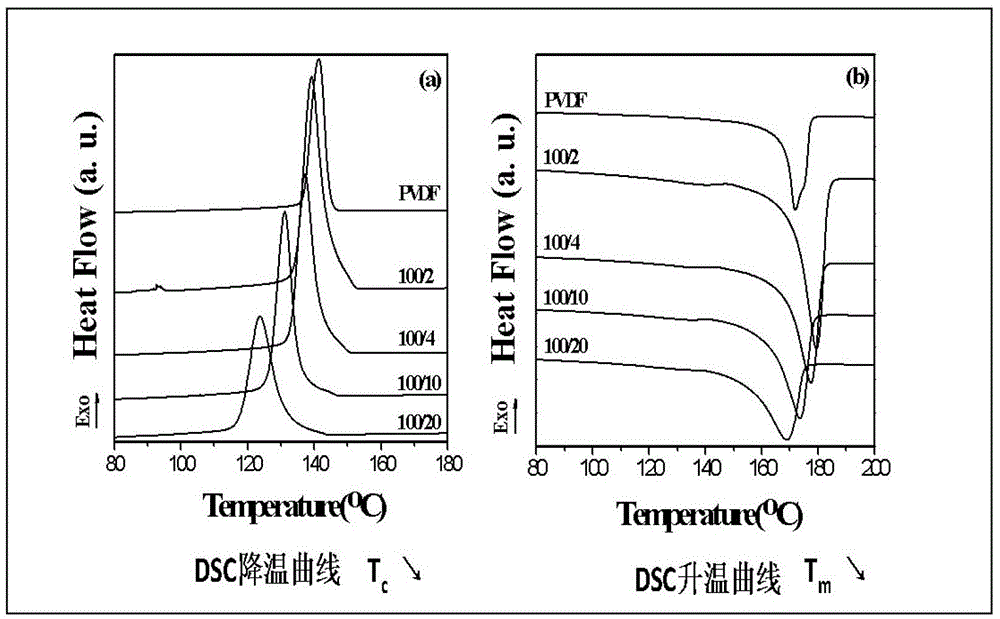

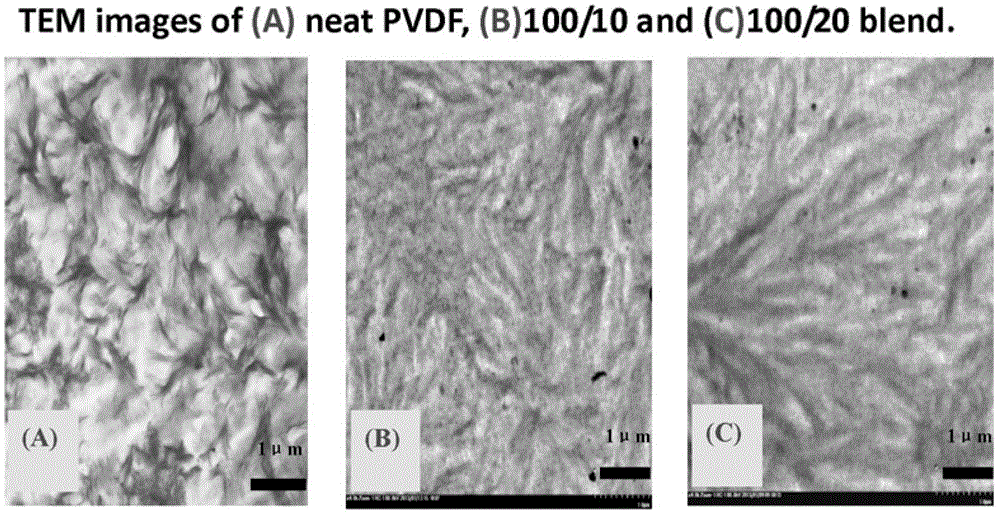

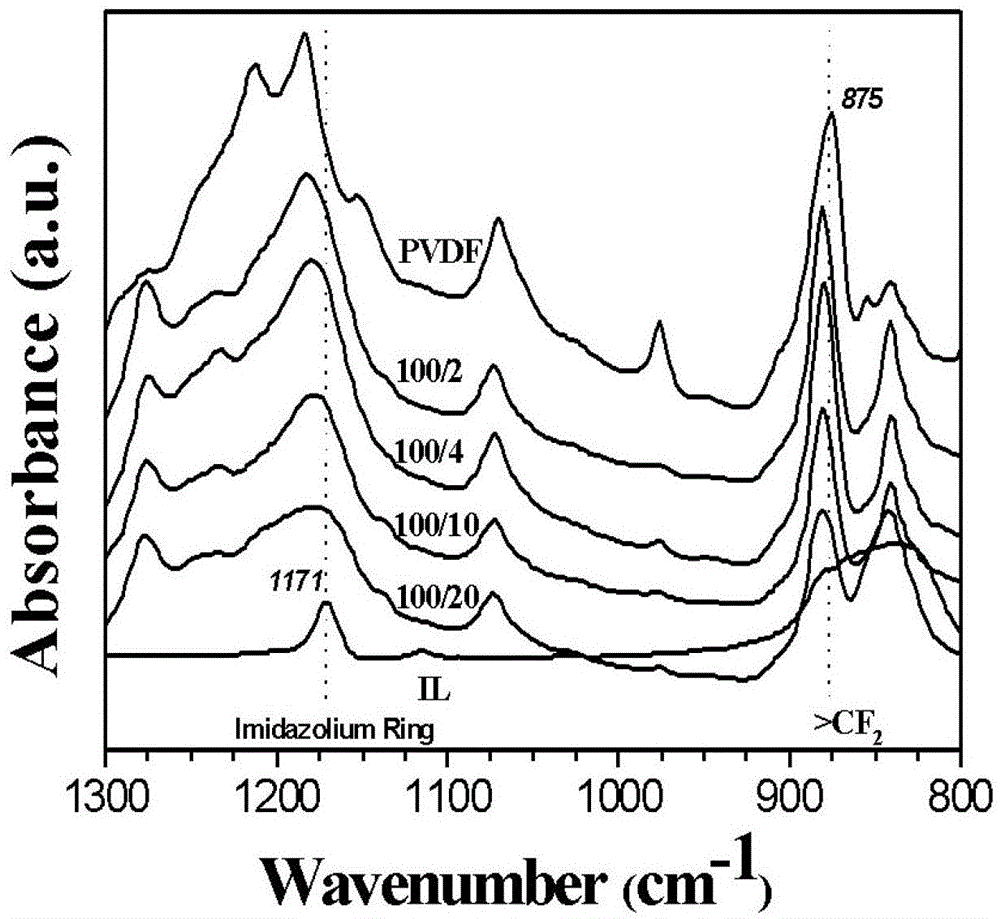

[0031] Add 193g of polyvinylidene fluoride, 3g of other additives, 4g of 1-butyl-3-methylimidazolium hexafluorophosphate into the Haake rheometer at 190°C for 15min at a speed of 50 rpm, and then pass through the twin-screw The extruder extrudes and cuts into pellets and packs after drying. The temperature of each zone of the twin-screw extruder is set at 160°C-190°C. The prepared composition was hot-pressed at 190°C, and its antistatic properties, mechanical properties and light transmittance were measured and analyzed by DSC, TEM and FTIR. The results of the analysis are shown in the accompanying drawings.

Embodiment example 2

[0033] Put 189g of polyvinylidene fluoride, 3g of other additives, and 8g of 1-butyl-3-methylimidazolium hexafluorophosphate into a Haake rheometer at 190°C for 15 minutes at a speed of 50 rpm, and then pass through a twin-screw The extruder extrudes and cuts into pellets and packs after drying. The temperature of each zone of the twin-screw extruder is set at 160°C-190°C. The prepared composition was hot-pressed at 190°C, and its antistatic properties, mechanical properties and light transmittance were measured and analyzed by DSC, TEM and FTIR. The results of the analysis are shown in the accompanying drawings.

Embodiment example 3

[0035] Put 177g of polyvinylidene fluoride, 3g of other additives, 20g of 1-butyl-3-methylimidazolium hexafluorophosphate into the Haake rheometer at 190°C for 15min, at a speed of 50 rpm, and then pass through the twin-screw The extruder extrudes and cuts into pellets and packs after drying. The temperature of each zone of the twin-screw extruder is set at 160°C-190°C. The prepared composition was hot-pressed at 190°C, and its antistatic properties, mechanical properties and light transmittance were measured and analyzed by DSC, TEM and FTIR. The results of the analysis are shown in the accompanying drawings.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com