Polypropylene halogen-free flame-retardant anti-static material, and preparation method and applications thereof

A flame retardant and antistatic, polypropylene technology, applied in the field of polypropylene halogen-free flame retardant and antistatic material and its preparation, can solve the problem of large addition of conductive polymer fillers, large addition of inorganic conductive fillers, and high environmental humidity dependence. and other problems, to achieve excellent mechanical properties and processability, optimized flame retardant effect, and excellent antistatic properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention also provides a method for preparing a polypropylene halogen-free flame-retardant antistatic material described in any one of the above-mentioned technical solutions, comprising the following steps:

[0034] mixing the above raw materials to obtain a raw material mixture;

[0035] The raw material mixture is melt-extruded to obtain a polypropylene halogen-free flame-retardant antistatic material.

[0036] In the present invention, the above-mentioned raw materials are mixed to obtain a raw material mixture. In the present invention, the mixing is preferably performed in a high-speed mixer. The present invention does not have any special requirements on the mixing order of the raw materials, and can be mixed in any order. In the present invention, the mixing speed of the mixing is independently preferably 1000-1800rpm, more preferably 1200-1600rpm, most preferably 1400rpm; the mixing time of the mixing is independently preferably 1-10min, more pre...

Embodiment

[0042] In all embodiments of the present invention, the conductive carbon black is a conductive material with permanent conductivity, its average particle size is 10-40nm, and its specific surface area should be greater than 200m 2 / g. The diameter of the outer surface of the carbon nanotube is 5-40 nm, and the length is 10-60 μm.

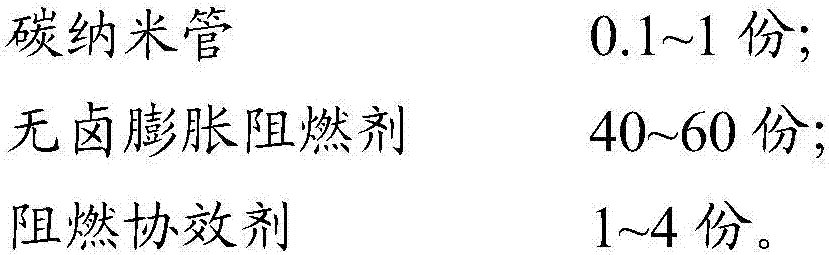

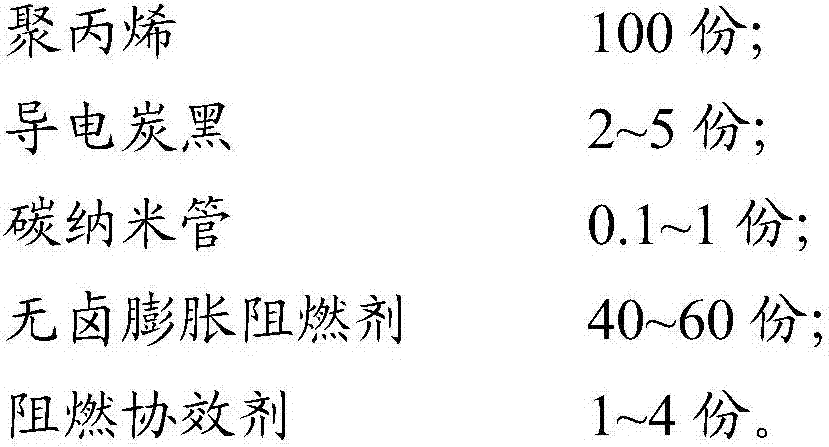

[0043] Raw material composition in table 1 embodiment 1~4 and comparative example 1

[0044]

[0045] Each raw material was weighed according to the mass parts in Table 1, mixed according to the parameters in Table 2, and then melted and extruded by a twin-screw extruder to prepare a polypropylene halogen-free flame-retardant antistatic material.

[0046] Process parameter and performance parameter result in table 2 embodiment 1~4 and comparative example 1

[0047]

[0048] It can be known from the above examples that the present invention provides a polypropylene halogen-free flame-retardant antistatic material and its preparation method a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com