Composite plate with electromagnetic shielding efficiency and antistatic performance and preparation method thereof

An electromagnetic shielding and composite board technology is applied in the technical field of composite materials to achieve the effects of good flame retardancy and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

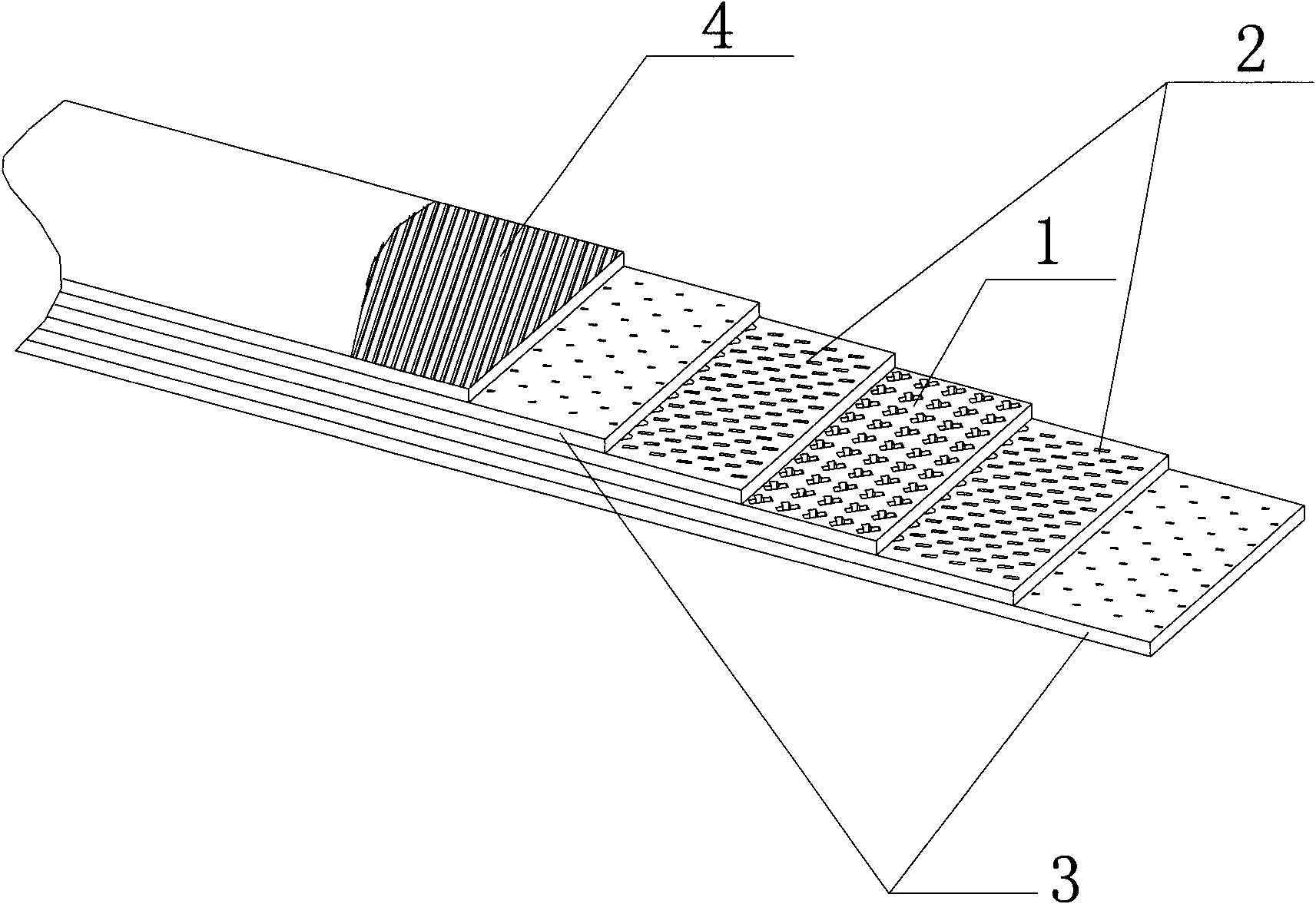

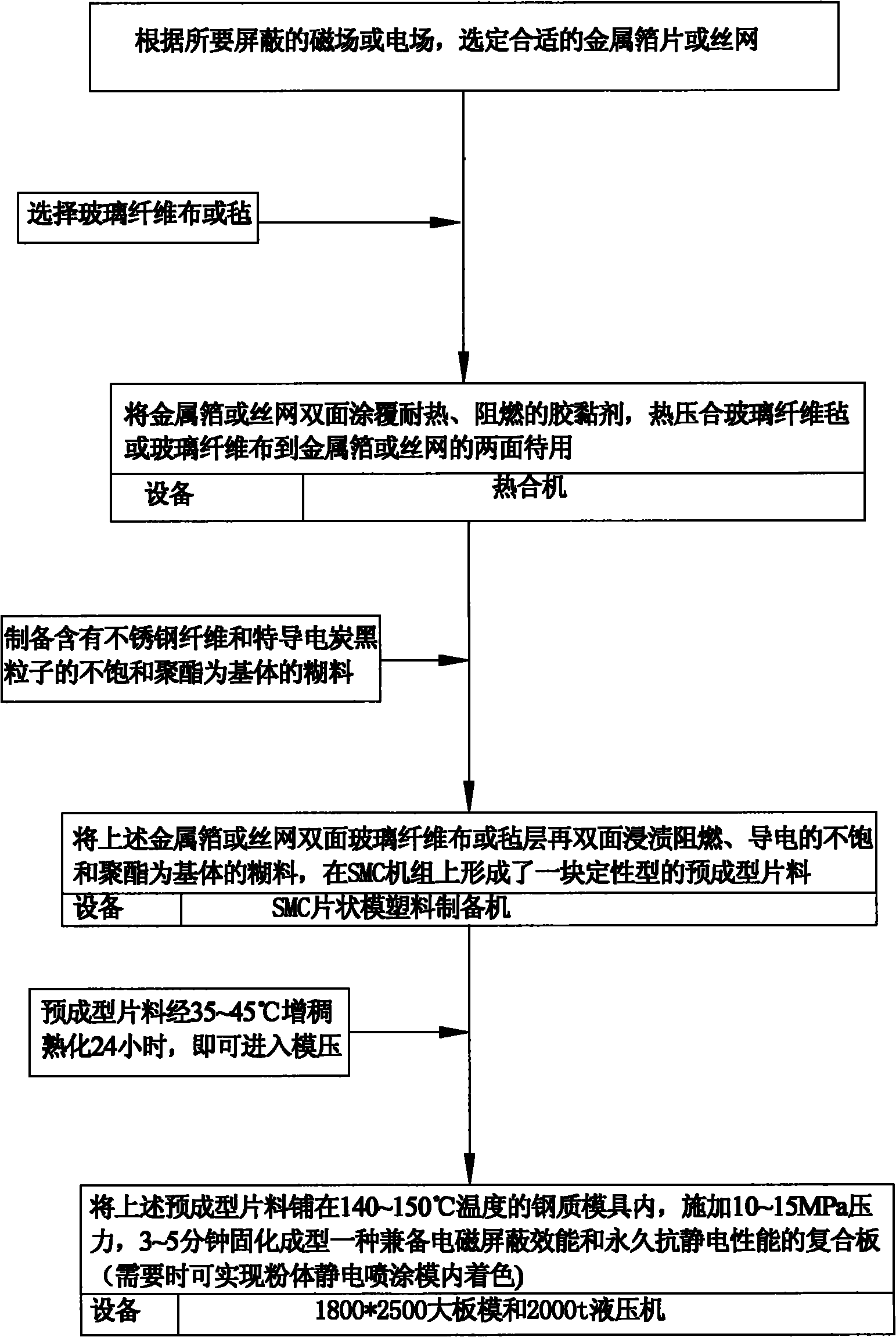

Embodiment 1

[0040]Aluminum foil with a thickness of 0.1mm is selected as the middle layer 1 of a good metal conductor, and adhesive is coated on both sides of the aluminum foil, and an aluminum foil fiber cloth heat sealing machine is used to heat-press SH-100 glass fiber mat (glass fiber fabric composite layer 2) on both sides of the aluminum foil. ), configure unsaturated polyester as the base according to the formula ratio, and the stainless steel fiber content in the paste is 5% (the proportioning ratio of each raw material for preparing the paste is: 17 parts of isophthalic unsaturated polyester, low shrinkage resin (polystyrene is 36wt%, monomeric styrene is 64wt%) 6 parts, polyethylene micropowder 2 parts, hydrated aluminum oxide 60 parts, stainless steel fiber 5 parts, special conductive carbon black 5 parts, viscosity reducer 1 part, trigger 0.5 parts of mold release agent, 0.5 parts of thickening agent); then the above-mentioned double-sided heat-pressed SH-100 glass fiber mat al...

Embodiment 2

[0043] Select 40-mesh brass wire mesh, double-sided hot-pressed EWR-400 glass fiber cloth, impregnate the paste containing 3% stainless steel fiber and 3% special conductive carbon black as the matrix of unsaturated polyester (each raw material for preparing the paste The dosage ratio is: 16 parts of o-phthalic unsaturated polyester, 8 parts of low-shrinkage resin (35wt% for polystyrene, 65wt% for monomeric styrene), 2 parts of polyethylene micropowder, 64 parts of hydrated aluminum oxide, stainless steel 3 parts of fiber, 3 parts of special conductive carbon black, 1 part of viscosity reducer, 0.5 part of initiator, 2 parts of release agent, 0.5 part of thickener), other preparation steps are the same as in Example 1, within the frequency range of 10MHz~1500MHz , Test its electromagnetic shielding effectiveness to more than 55dB.

Embodiment 3

[0045] Select 80 mesh stainless steel wire mesh, double-sided heat-bonded EWR-400 glass fiber cloth, impregnate the paste containing 3% stainless steel fiber and 3% special conductive carbon black unsaturated polyester as the matrix (the proportioning ratio of each raw material for preparing the paste It is: 19 parts of bisphenol A type unsaturated polyester, 9 parts of low shrinkage resin (40wt% for polystyrene, 60wt% for monomer styrene), 3 parts of polyethylene micropowder, 59 parts of hydrated aluminum oxide, 3 parts of stainless steel fiber 3 parts, 3 parts of special conductive carbon black, 1 part of viscosity reducer, 0.5 part of initiator, 2 parts of release agent, 0.5 part of thickener), other preparation steps are the same as Example 1, in the range of 100KHz~100MHz frequency, test Its electromagnetic shielding effectiveness reaches above 60dB.

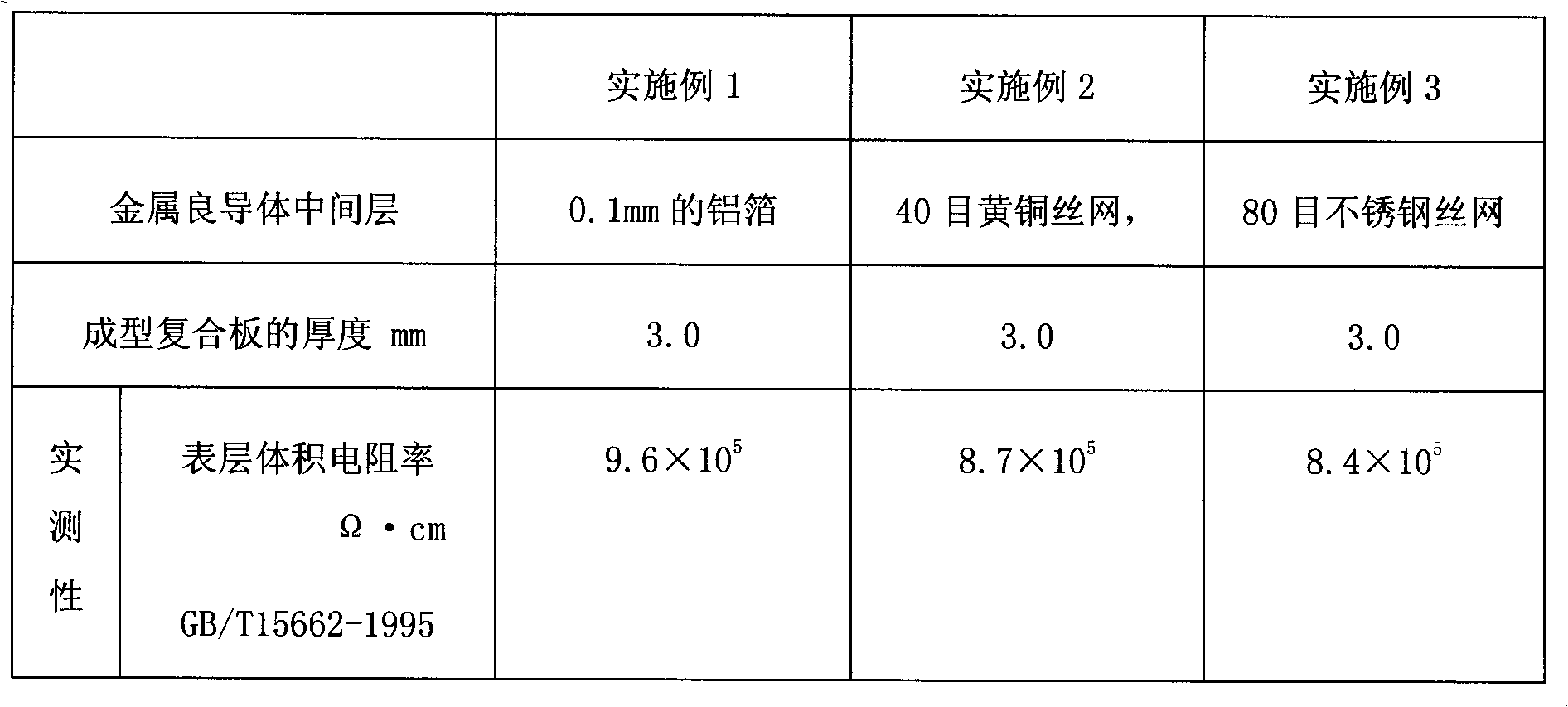

[0046] The actual measurement results of the electromagnetic shielding effectiveness and antistatic ability of the formed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com