Preparation method of antistatic silicone rubber

A silicone rubber and antistatic technology, applied in the field of rubber, can solve problems such as poor compatibility, achieve good compatibility, improve bonding strength, and improve adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

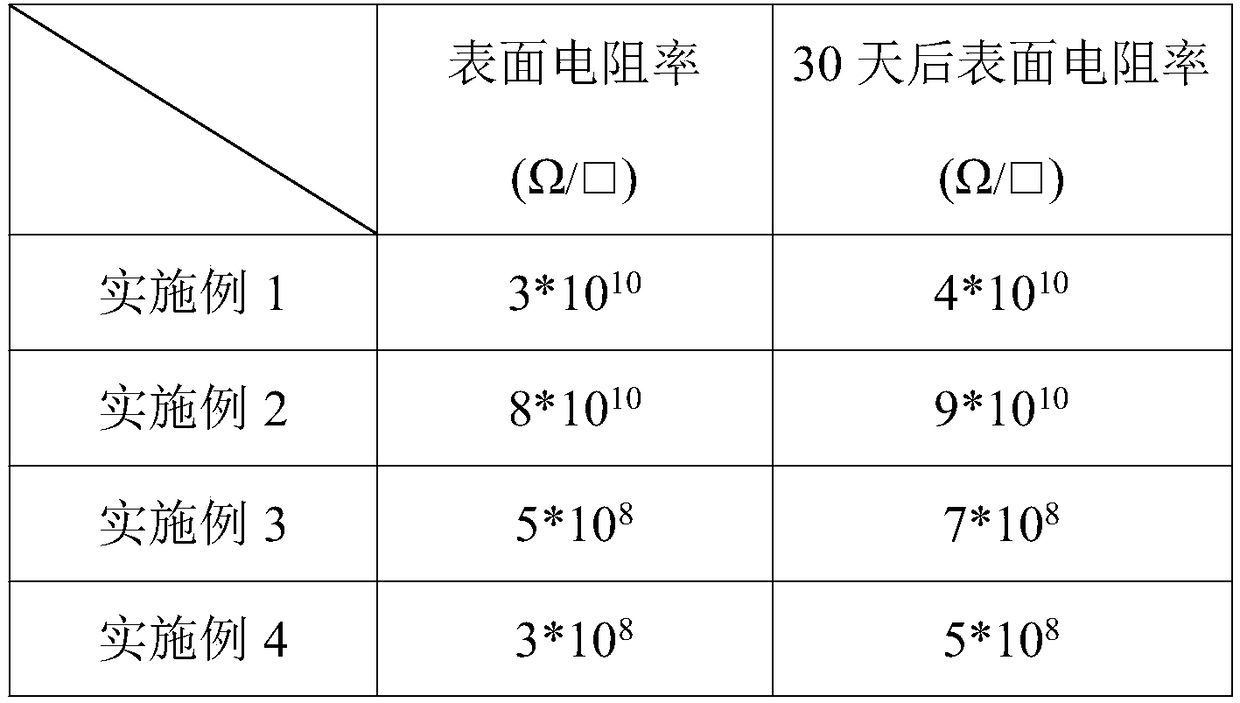

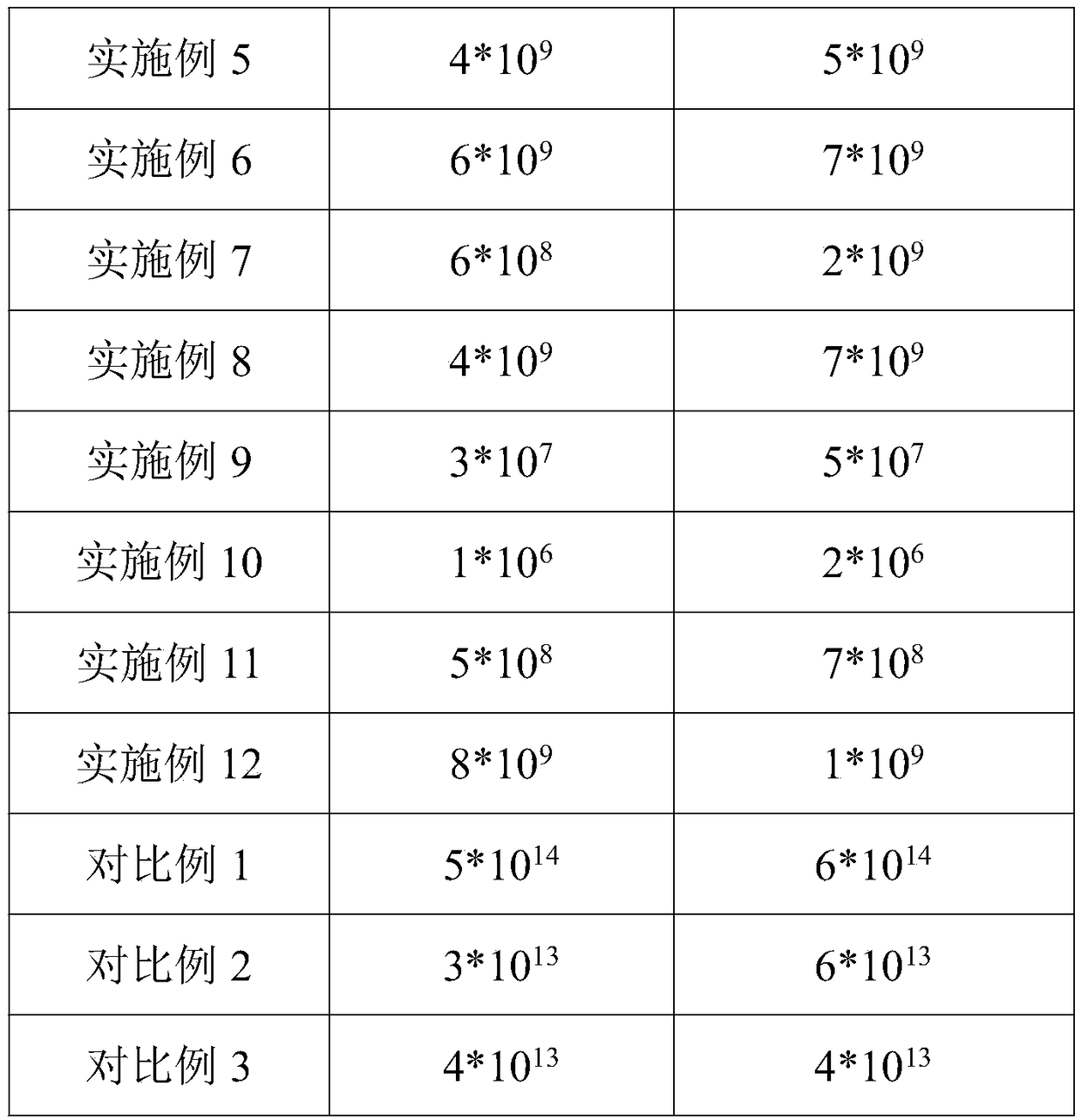

Examples

preparation example Construction

[0034] The preparation method of antistatic silicone rubber provided by the invention comprises:

[0035] S1, providing a silicone rubber, performing surface treatment on the silicone rubber, so that the surface of the silicone rubber has polar groups;

[0036] S2, coating a polyfunctional compound on the surface of the silicone rubber with a polar group to form a first coating, allowing the polyfunctional compound to react with the polar group to form a chemical bond;

[0037] S3, covering the surface of the first coating with an antistatic agent and a binder to form a second coating, allowing the binder to react with the multifunctional compound to form a chemical bond, and then curing to obtain an antistatic Silicone Rubber.

[0038] In step S1, there are many methods for surface treatment of silicone rubber, including solvent treatment, coupling agent treatment, flame treatment, ultraviolet light irradiation treatment, plasma surface treatment and the like. When choosing...

Embodiment 1

[0071] Place the silicone rubber sample in an ultraviolet ozone cleaning machine. The temperature of the ultraviolet ozone cleaning machine is 20°C. During the ultraviolet light irradiation process, the ultraviolet light has a wavelength of 100nm to 300nm and is irradiated for 10 minutes to obtain the surface-treated silicone rubber sample A1.

[0072] Prepare 1 part of 3-aminopropyltriethoxysilane, 5 parts of water, and 94 parts of ethanol solution, spray the solution on the surface of the treated silicone rubber sample A1, and the spraying amount is 0.1g / cm 2 Solution, heated at 70° C. for 3 minutes to obtain silicone rubber B1 with reactive groups grafted on the surface.

[0073] Mix epoxy resin glue A and glue B in a ratio of 3:1, add 2wt% octadecyl dimethyl hydroxyethyl quaternary ammonium nitrate, mix evenly, and coat it on silicone rubber B1. Electrostatic silicone rubber1.

Embodiment 2

[0075]Place the silicone rubber sample in an ultraviolet ozone cleaning machine. The temperature of the ultraviolet ozone cleaning machine is 20°C. During the ultraviolet irradiation process, the ultraviolet light has a wavelength of 100nm to 300nm and is irradiated for 60 minutes to obtain the surface-treated silicone rubber sample A2.

[0076] Prepare 1 part of γ-glycidyl etheroxypropyl trimethoxysilane, 5 parts of water, and 94 parts of ethanol solution, spray the solution on the surface of the treated silicone rubber sample A2, and heat at 70°C for 3 minutes to obtain surface grafting Silicone rubber B2 with reactive groups.

[0077] Mix epoxy resin glue A and glue B at a ratio of 3:1, add 2wt% N-hexadecylpyridinium nitrate, mix evenly, coat on silicone rubber B2, and obtain antistatic silicone rubber 2 after curing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com