Halogen-free flame-retardance anti-static polypropylene composite material and preparation methods thereof

A flame retardant, antistatic and composite material technology, applied in the field of material chemistry, can solve the problems of large amount of antistatic agent, non-environmental protection of flame retardant, high toxicity of smoke, etc., and achieve excellent antistatic performance, reduce impact, and reduce price low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

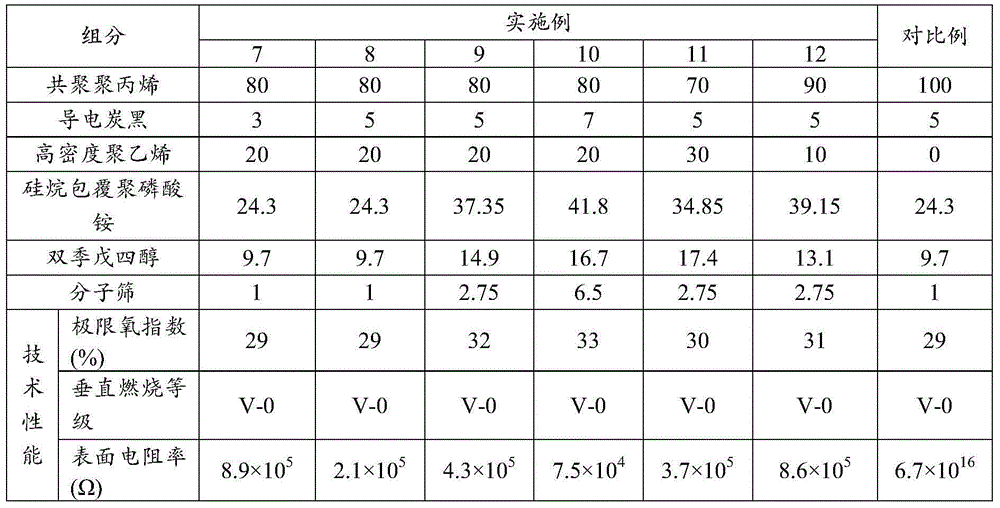

Examples

Embodiment 2

[0037] Weigh 70g of copolymerized polypropylene; 7g of conductive carbon black, with an average particle size of 60nm and a specific surface area of 200m 2 / g; conduction promoter 30g, melt index 15g / 10min, test conditions 2.16kg, 190°C, including 20g high-density polyethylene, 5g medium-density polyethylene, 5g low-density polyethylene; silane-coated ammonium polyphosphate 42.05 g, 21g of dipentaerythritol, the purity of dipentaerythritol is 85wt%, and 1.95g of molecular sieves to obtain 65g of halogen-free intumescent flame retardant.

[0038] A high-speed mixer was used to mix the raw materials for 3 minutes, and then a screw extruder was used to melt, mix and extrude to obtain 172 g of a halogen-free flame-retardant and antistatic polypropylene composite material.

[0039]The screw speed of the extruder is 100rpm, the temperature of the feed section of the extruder is 165°C, the temperature of the compression section is 165°C, the temperature of the plasticizing section ...

Embodiment 3

[0042] Weigh 15g of copolymerized polypropylene, 60g of homopolypropylene; 5g of carbon nanotubes, 10-20nm in diameter, 30μm in length; 25g of high-density polyethylene, with a melt index of 10g / 10min, and the test conditions are 2.16kg, 190°C; melamine Coated ammonium polyphosphate 37.1g, dipentaerythritol 12.4g, dipentaerythritol purity 90wt%, molecular sieve 3g, zinc oxide 2.5g, obtained 55g halogen-free intumescent flame retardant; antioxidant 0.8g.

[0043] A high-speed mixer was used to mix the raw materials for 5 minutes, and then a screw extruder was used to melt, mix and extrude to obtain 160.8 g of a halogen-free flame-retardant antistatic polypropylene composite material.

[0044] The screw speed of the extruder is 300rpm, the temperature of the feed section of the extruder is 155°C, the temperature of the compression section is 175°C, the temperature of the plasticizing section is 175°C, the temperature of the homogenization section is 185°C, and the die temperature...

Embodiment 4

[0047] Weigh 85g of homopolypropylene; 4g of conductive carbon fiber, diameter 7μm, length 3mm; medium density polyethylene 15g, melt index 25g / 10min, test condition is 2.16kg, 190°C; epoxy resin coated ammonium polyphosphate 10g, silane 20.55g of coated ammonium polyphosphate, 12.2g of dipentaerythritol with a purity of 90wt%, 0.5g of kaolin, 1g of sepiolite, and 0.75g of zinc borate were mixed to form 45g of halogen-free intumescent flame retardant; 0.5g of light stabilizer.

[0048] First, use a high-speed mixer to mix the homopolypropylene and the halogen-free intumescent flame retardant for 3 minutes, then use a screw extruder to melt and mix and extrude to obtain a flame retardant composition A; the screw speed of the extruder is 300rpm, extruded The temperature of the feed section of the machine is 155°C, the temperature of the compression section is 165°C, the temperature of the plasticizing section is 185°C, the temperature of the homogenization section is 185°C, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com