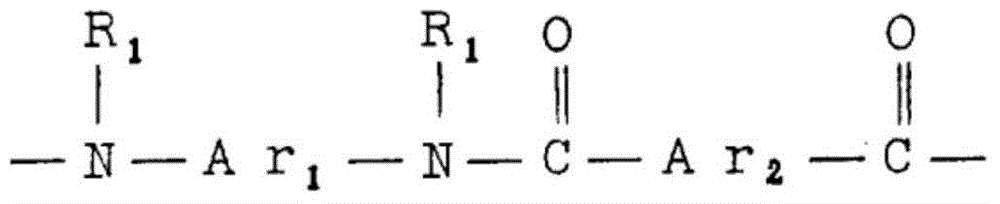

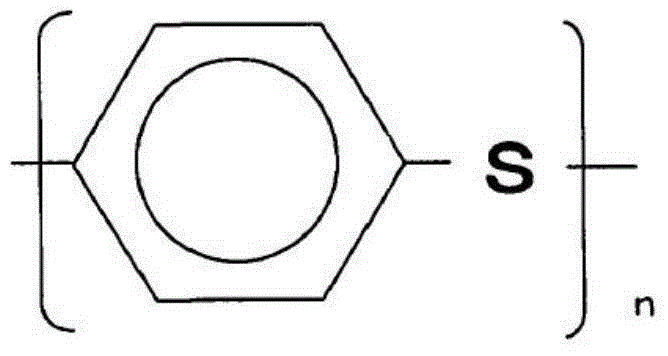

Yarn and fabric made of polyphenylene sulfide fibers and blended fibers based on aromatic polyamide and Astrel 360 and production method of yarn and fabric

A kind of technology of aromatic polyamide and polyphenylene sulfide fiber, which is applied in the field of flame retardant yarn and can solve the problems of poor heat-resistant hydrolysis performance and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0087] In another embodiment, the present invention relates to a method for the preparation of the above-mentioned yarn, said method comprising:

[0088] (i) forming a fiber mixture comprising 30-70 parts by weight of aramid- and polyarylsulfone-based blend fibers (A) and 30-70 parts by weight of polyphenylene sulfide fibers (B), The blended fiber (A) based on aromatic polyamide and polyarylsulfone contains 40-98wt% aromatic polyamide and 2-60wt% polyarylsulfone, and the aromatic polyamide and polyarylsulfone are mixed. as well as

[0089] (ii) spinning the fiber mixture into fibers.

[0090] Preferably, the fiber mixture comprises 70-30% by weight of aramid-polyarylsulfone-based blended fibers (A) and 30-70% by weight of polyphenylene sulfide fibers (B).

[0091] Preferably, the fiber mixture comprises 60-40% by weight of blended fibers based on aramid and polyarylsulfone (A) and 40-60% by weight of polyphenylene sulfide fibers (B).

[0092] Preferably, the fiber mixture ...

Embodiment 1

[0122] Aramid and polyarylsulfone based blend fiber / PPS fiber 50 / 50 blend, spinning count 16s / 2, fabric weight 450gsm, plain weave

[0123] 1. Spinning: put 50% blended fiber based on aromatic polyamide and polyarylsulfone, and 50% PPS fiber in the bale grabbing area and send it to A035 cotton feeding machine → FA106 opening machine → A092 cotton box through A2001D bale grabbing machine → Cotton feeding machine → FA231A carding machine → FA302 drawing frame → FA481 roving frame → FA506 spinning frame to make industrial protective clothing yarn.

[0124] 2. Weaving: The finished yarn is made into a bobbin by the GS669 winding machine, and then sent to the GA747 rapier loom to make plain weave fabric.

Embodiment 2

[0126] Aramid and polyarylsulfone based blend fiber / PPS fiber 70 / 30 blend, spinning count 30s / 2, fabric weight 250gsm, twill weave

[0127] 1. Spinning: Put 70% blended fiber based on aromatic polyamide and polyaryl sulfone, 30% PPS in the bale grabbing area and send it to A035 cotton feeding machine through A2001D bale grabbing machine → FA106 opening machine → A092 cotton box → Cotton feeding machine → FA231A carding machine → FA302 drawing frame → FA481 roving frame → FA506 spinning frame to make industrial protective clothing yarn.

[0128] 2. Weaving: The finished yarn is made into a bobbin by the GS669 winder, and sent to the GA747 rapier loom to make a twill fabric.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com