Dope dyed flame retardant polyester fibers, textle products therefrom and the method of manufacturing thereof

A technology of flame-retardant polyester and polyester fiber, applied in the field of flame-retardant polyester fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5 and comparative example 1~3

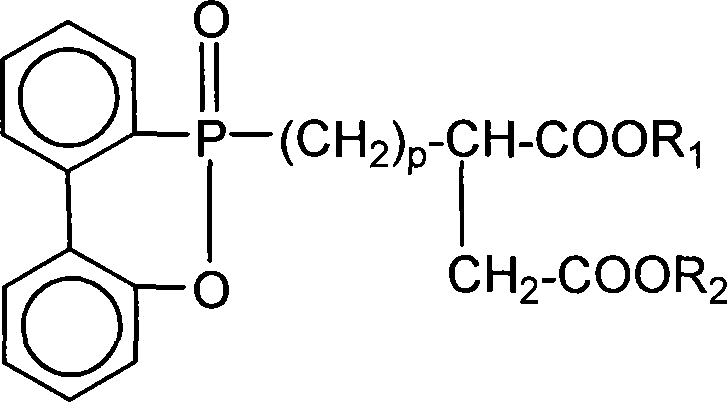

[0049] A slurry of 8650 g of terephthalic acid (hereinafter referred to as "TPA") and 2700 g of ethylene glycol (hereinafter referred to as "EG") was subjected to an esterification reaction using a semi-batch process. The oligomer (which was prepared to have the same composition as in the slurry) was stirred in the esterification reactor while the temperature of the reactor was maintained at 250-260°C. After the slurry introduction was completed, the esterification reaction was continued for 30 minutes, thereby reaching an esterification reaction rate of 96.5%. The prepared oligomers are transferred to the polycondensation reactor. Use general formula 1 compound (wherein p is 1, R 1 and R 2 for CH 2 CH 2 OH) concentration of 65% by weight of the EG solution as a flame retardant. 1380 g of a flame retardant solution was introduced into the reactor, and then manganese acetate and phosphoric acid having concentrations of 44 ppm and 75 ppm in terms of manganese and phosphorus...

Embodiment 6

[0070] The false-twisted yarn of flame-retardant polyester and commercially available flame-retardant polyester false-twisted yarn SDM 150 / 144 (Hyosung, Korea) of the dope dyed flame-retardant polyester prepared in embodiment 1 were used as weft yarn and warp yarn to weave double-sided satin respectively, Its performance as a shade was then evaluated.

[0071] The flame retardancy of the shade was evaluated according to US Standard NFPA 701, and the shade passed the test. In addition, when the shading degree of the shade was evaluated in accordance with Japanese standard JIS L 1055, the result was 99.8%.

[0072] As described above, the dope-dyed flame-retardant polyester fiber according to the present invention has excellent flame retardancy, UV stability, and fastness. In particular, use of the fiber according to the present invention to prepare a blackout curtain or the like can provide excellent flame retardancy and light shielding properties at the same time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com