Antistatic PVC (Polyvinyl Chloride) pipe

A PVC pipe, antistatic technology, applied in the direction of drill pipe, casing, synthetic resin layered products, etc., can solve the problems of poor antistatic performance, achieve good market application prospects, permanent antistatic performance and flame retardant performance, Strong impact resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

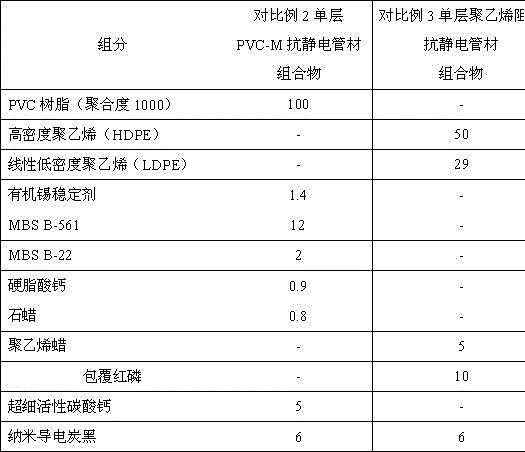

[0018] The proportioning components of the antistatic PVC pipe antistatic inner and outer layers and the PVC-M intermediate layer composition are as shown in Table 1:

[0019] Table 1 Example 1 three-layer co-extruded PVC-M pipe (by weight)

[0020] components PVC-M interlayer composition Antistatic inner and outer layer composition PVC resin (polymerization degree 1000) 100 - PVC resin (polymerization degree 700) - 100 Organotin stabilizer 17MOK 1.0 0.8 MBS B-22 0 4 MBS B-561 10 0 DOP - 5 Calcium stearate 1.2 0.75 Microcrystalline Wax 0.9 0.55 Nano calcium carbonate 0 - Nano conductive carbon black - 6

Embodiment 2

[0022] The proportioning components of the antistatic PVC pipe antistatic inner and outer layers and the PVC-M intermediate layer composition are as shown in Table 2:

[0023] Table 2 The ratio of the three-layer co-extruded PVC-M pipe composition in Example 2 (by weight)

[0024] components PVC-M interlayer composition Antistatic inner and outer layer composition PVC resin (polymerization degree 1000) 100 - PVC resin (polymerization degree 700) - 100 Organotin stabilizer 17MOK 1.5 1.2 MBS B-22 2 8 MBS B-561 13 0 DOP - 10 Calcium stearate 2.0 1.15 Microcrystalline Wax 1.5 0.85 Nano calcium carbonate 5 - Nano conductive carbon black - 6

Embodiment 3

[0026] The proportioning components of the antistatic PVC pipe antistatic inner and outer layers and the PVC-M intermediate layer composition are as shown in Table 3:

[0027]Table 3 The ratio of the three-layer co-extruded PVC-M pipe composition in Example 3 (by weight)

[0028] components PVC-M interlayer composition Antistatic inner and outer layer composition PVC resin (polymerization degree 1000) 100 - PVC resin (polymerization degree 700) - 100 Organotin stabilizer 17MOK 1.2 1.0 MBS B-22 2 8 MBS B-561 11 0 DOP - 7 Calcium stearate 1.5 0.90 Microcrystalline Wax 1.2 0.70 Nano calcium carbonate 3 - Nano conductive carbon black - 6

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com