Air kinetic energy ejection launcher for spacecraft

A technology for launching devices and spacecraft, which is applied in the direction of launching/dragging transmissions, aerospace vehicles, aircraft, etc., can solve the problems of prone to engine failure and high cost of spacecraft launch technology, so as to increase the effective weight and scale, reduce Dead volume, effect of reducing launch weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

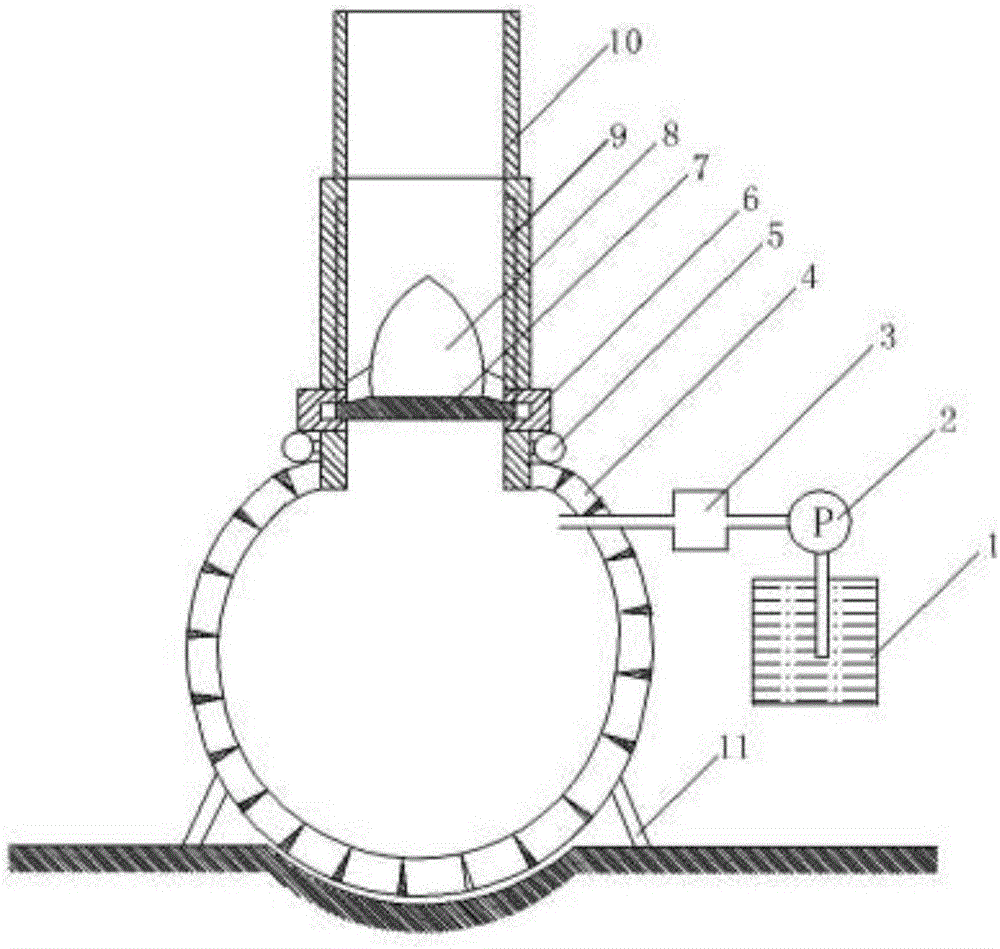

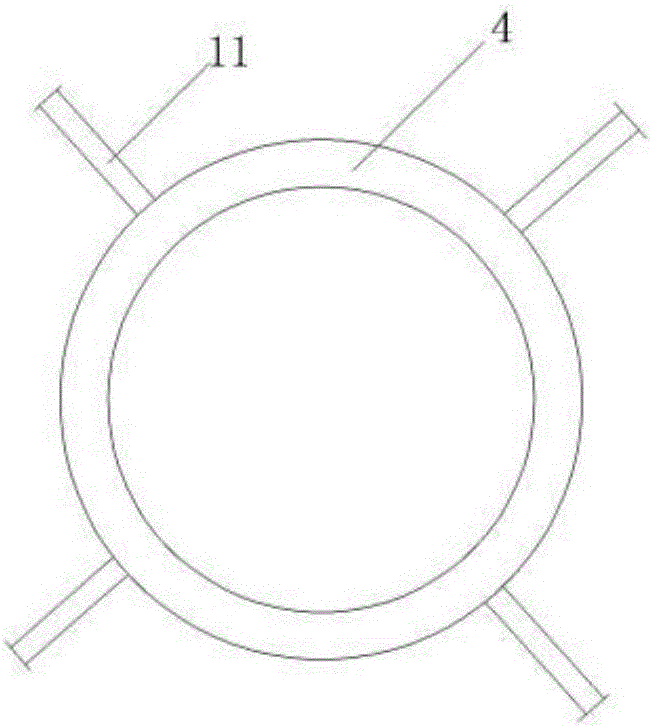

[0036] Such as figure 1 , 3 As shown in ~10, the spacecraft aerodynamic ejection launch device of the present embodiment includes an inflation mechanism and a high-pressure air spherical tank 4, and the inflation mechanism communicates with the high-pressure air spherical tank 4 to provide vaporized gas for the high-pressure air spherical tank. It includes liquefied air storage tank 1, liquefied air pump 2 and heating jacket 3. The liquefied air in the liquefied air storage tank is pumped out by the liquefied air pump and then heated by the heating jacket to obtain vaporized gas, which is then introduced into the high-pressure air spherical tank. The top opening of the high-pressure air spherical tank 4 is equipped with a gear-shaped blind cover 6 on the inner edge, and a gear-shaped blind cover 7 on the outer edge is installed in the blind cover. The blind cover 6 is connected to the electromagnetic drive device 5, The electromagnetic driving device 5 has a pressure sensor, ...

Embodiment 2

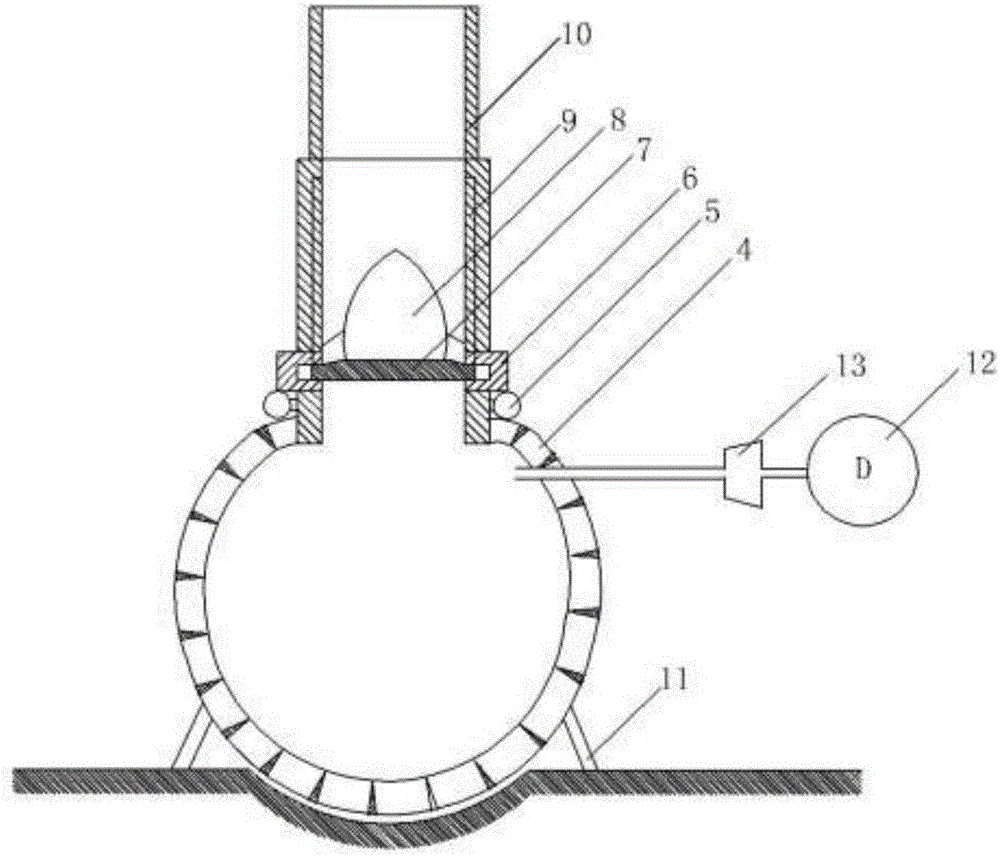

[0041] Such as figure 2 As shown, different from Embodiment 1, the inflation mechanism of the spacecraft air kinetic energy catapult launching device of this embodiment includes a motor 12 and an air compressor 13, and the motor drives the air compressor to pump compressed air into the high-pressure air spherical tank ; And the high-pressure air spherical tank of the present embodiment is that after the special-shaped pipes with trapezoidal cross-section are rolled into a high-pressure air spherical tank shape, they are surfacing welded in the naturally formed seam, and filled into the lumen of the special-shaped pipes. It is made of water with a pressure 20% higher than the preset value of the air pressure of the high-pressure air spherical tank. Other structures are the same as those of Embodiment 1 except for the above-mentioned structures that are different from Embodiment 1.

[0042] The spacecraft launch program of the spacecraft aerodynamic energy ejection launching d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com