Pole component of solid sealed terminal

A technology of solid-sealed poles and pole parts, which is applied in the direction of electrical components, high-voltage air circuit breakers, electric switches, etc., can solve the problems of excessive local field strength, concentrated field strength, and large solid-sealed poles as a whole. Product productivity, reduction of environmental impact, effects of equipment size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

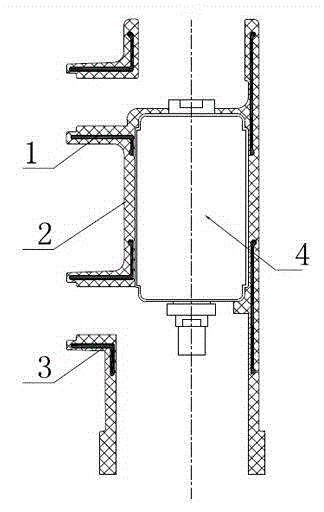

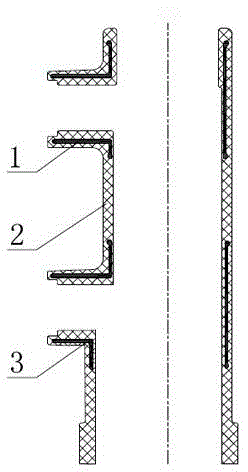

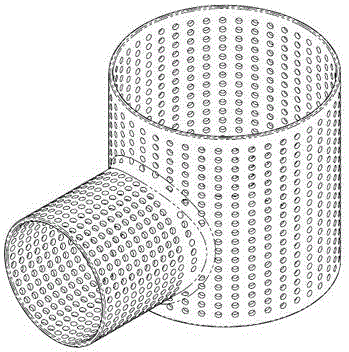

[0018] Example as figure 1 As shown, a pole part of a solid-sealed pole includes an upper shield 1, a lower shield 3 and a vacuum interrupter assembly 4, and the upper shield 1 and the lower shield 3 are embedded and fixed on the solid-sealed pole by casting insulating material 2 In the shell of the column, the vacuum interrupter assembly 4 is fixed in the shell of the solid-sealed pole parallel to the axial direction of the upper shield 1 and the lower shield 3, and the insulating material 2 is made of epoxy resin, polyester Amide, polyethylene or other synthetic resins, the upper shield 1 is mechanically connected or cast into one body with the upper high-voltage conductor of the embedded pole, and the lower shield 3 is mechanically connected or cast into the lower high-voltage conductor of the embedded pole. Pouring one. Through the introduction of upper and lower shielding, high voltage is introduced into the interior of the insulating material with high dielectric streng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com