Flame-proof antistatic master material and production method thereof

A flame retardant and antistatic masterbatch technology, applied in the field of flame retardant and antistatic masterbatch and its preparation, can solve the problems that the migration cannot be permanently antistatic, affect the performance and cost of the material, and affect the scope of application, and achieves low cost and processing. The effect of convenience, permanent flame retardancy and antistatic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

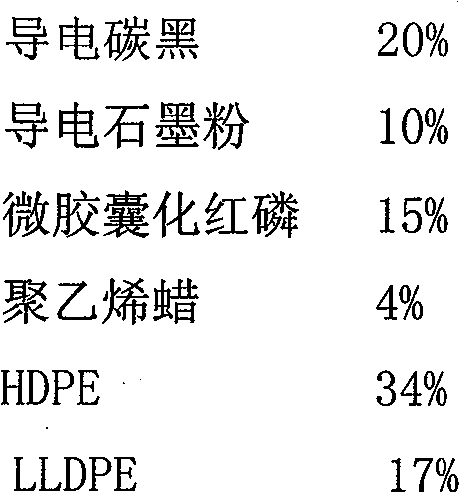

[0019] Flame-retardant antistatic masterbatch of the present invention, its weight consists of:

[0020]

[0021] The above materials are kneaded in a pressurized kneader for 30 minutes to 50 minutes at a temperature of 180°C, and then granulated with twin-screws at a temperature of 130°C to 180°C.

Embodiment 2

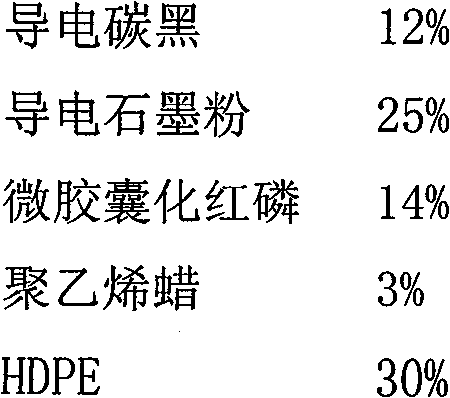

[0023] Flame-retardant antistatic masterbatch of the present invention, its weight consists of:

[0024]

[0025]

[0026] The preparation method is the same as before.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com