Flame-retardant and antibacterial polyester fiber for mattress filling and production method thereof

A polyester fiber, a production method technology, applied in the direction of fire-retardant and flame-retardant filament manufacturing, fiber processing, fiber type, etc., can solve the problems of poor flame-retardant performance, weakened flame-retardant performance, poor flame-retardant sponge, etc. performance and comfort, improved mechanical properties, good thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

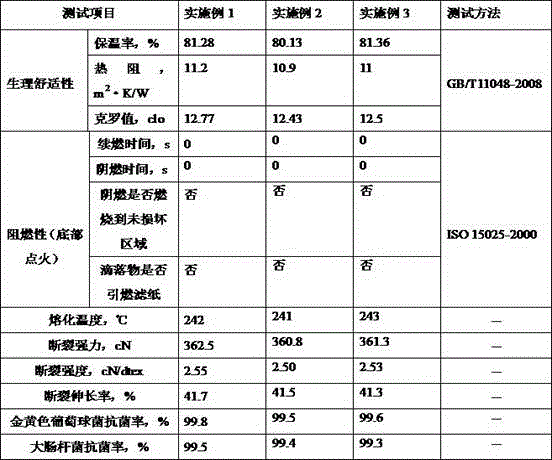

Examples

Embodiment 1

[0022] A method for making a flame-retardant and antibacterial polyester fiber for mattress filling, comprising the following steps:

[0023] Step 1, raw material treatment: vacuum-dry PET resin at 95°C for 35 hours to obtain PET resin dry material, vacuum-dry nano-montmorillonite at 65°C for 4 hours to obtain nano-montmorillonite dry material, and dry nano-silica powder at 115 Vacuum drying at ℃ for 32 hours to obtain dry nano-silica powder;

[0024] Step 2, PET resin modification: according to the number of parts by mass, after mixing and stirring 55 parts of PET resin dry material, 1.25 parts of nanometer montmorillonite dry material and 0.6 part of nano silicon micropowder dry material, then add 0.13 part of six ( 4-formylphenoxy)cyclotriphosphazene, continue to mix and stir evenly, granulate at 242°C, and then melt-spin at 292°C to obtain polyester fibers, wherein the mixing and stirring use a high-speed mixer Carry out, stirring speed is 900r / min;

[0025] Step 3, poly...

Embodiment 2

[0028] A method for making a flame-retardant and antibacterial polyester fiber for mattress filling, comprising the following steps:

[0029] Step 1, raw material treatment: vacuum-dry PET resin at 90°C for 35 hours to obtain PET resin dry material, vacuum-dry nano-montmorillonite at 60°C for 5 hours to obtain nano-montmorillonite dry material, and dry nano-silica powder at 110 Vacuum drying at ℃ for 35 hours to obtain dry nano-silica powder;

[0030] Step 2, PET resin modification: according to the number of parts by mass, after mixing and stirring 50 parts of PET resin dry material, 1.2 parts of nano-montmorillonite dry material and 0.4 part of nano-silica powder dry material, and then adding 0.1 part of six ( 4-formylphenoxy)cyclotriphosphazene, continue to mix and stir evenly, granulate at 240°C, and then melt-spin at 290°C to obtain polyester fibers, wherein the mixing and stirring uses a high-speed mixer Carry out, stirring speed is 800r / min;

[0031] Step 3, polyester...

Embodiment 3

[0034] A method for making a flame-retardant and antibacterial polyester fiber for mattress filling, comprising the following steps:

[0035] Step 1, raw material treatment: vacuum-dry PET resin at 100°C for 30 hours to obtain PET resin dry material, vacuum-dry nano-montmorillonite at 65°C for 3 hours to obtain nano-montmorillonite dry material, and dry nano-silica powder at 120 Vacuum drying at ℃ for 30 hours to obtain dry nano-silica powder;

[0036] Step 2, PET resin modification: according to the number of parts by mass, after mixing and stirring 60 parts of PET resin dry material, 1.3 parts of nanometer montmorillonite dry material and 0.8 part of nano silicon micropowder dry material, then add 0.15 part of six ( 4-formylphenoxy)cyclotriphosphazene, continue to mix and stir evenly, granulate at 245°C, and then melt-spin at 295°C to obtain polyester fibers, wherein the mixing and stirring use a high-speed mixer Carry out, stirring speed is 1000r / min;

[0037] Step 3, pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com