Preparation method of polyether material, polyether film and preparation method thereof

A technology of polyester material and polyester film, which is applied in the field of preparation of polyester materials, can solve the problems of low flame retardancy of polyester film and inability to solve the problem of heat and humidity resistance of polyester film, and achieve high heat and humidity resistance of flame retardants , Excellent physical and mechanical properties and electrical insulation properties, the effect of high flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

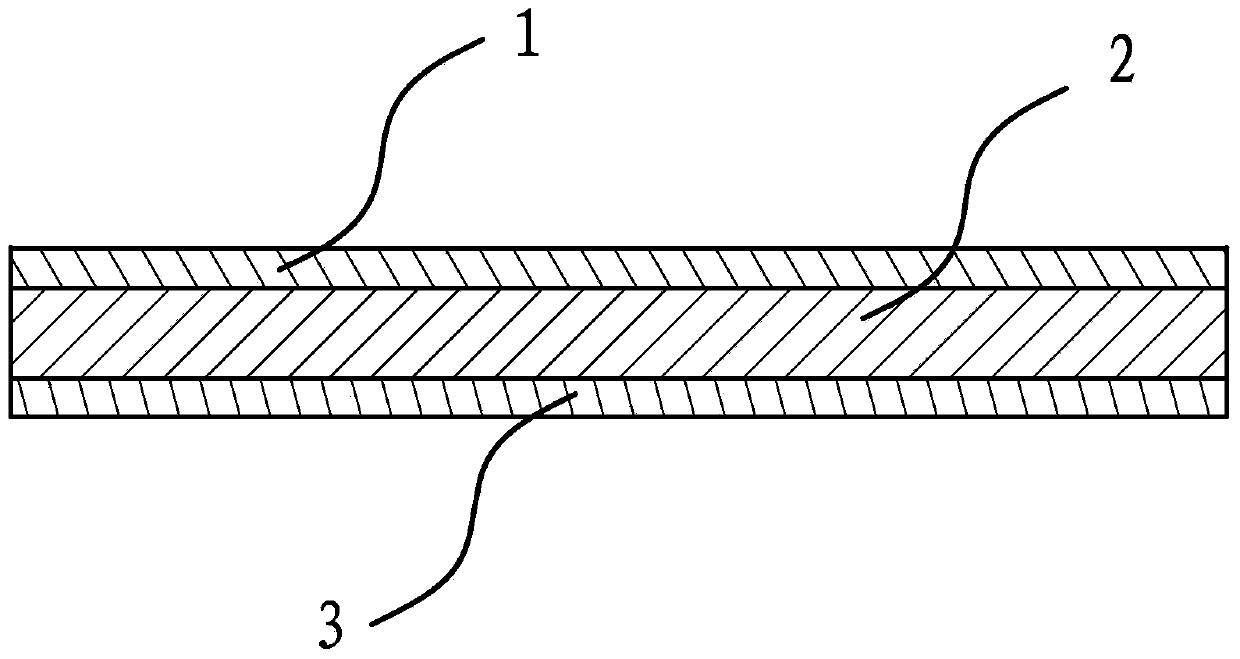

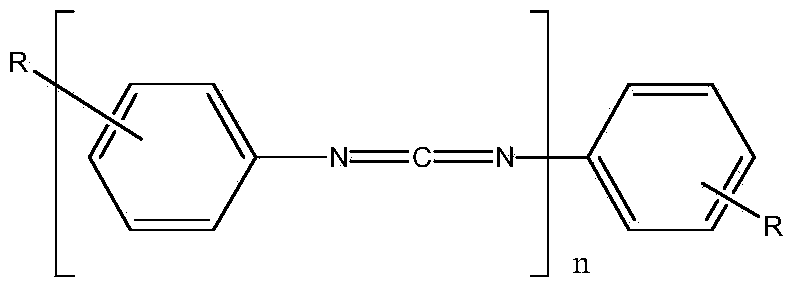

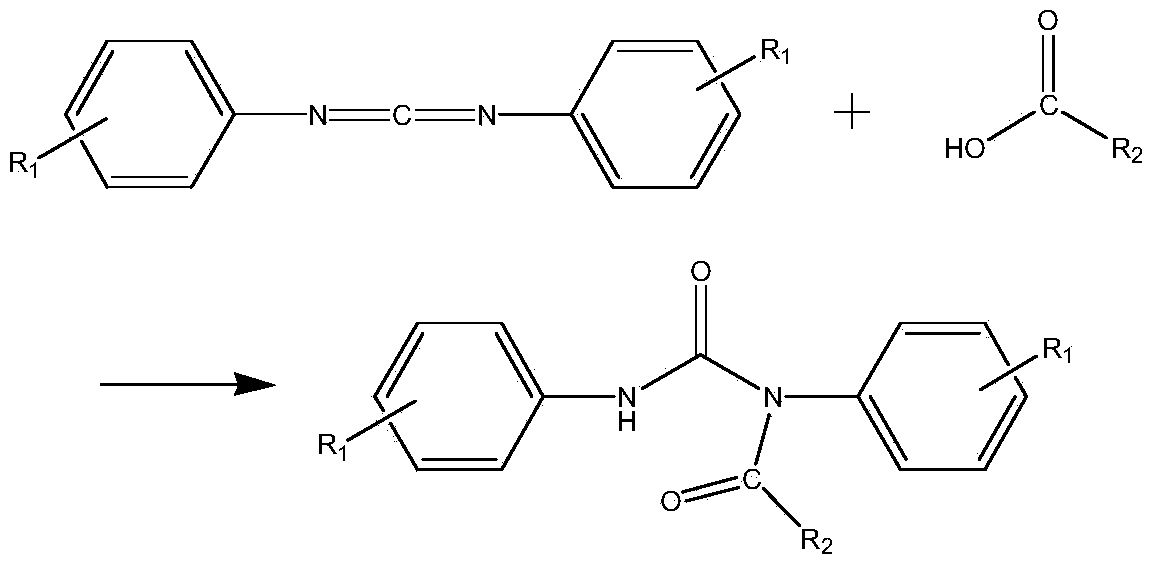

Image

Examples

Embodiment 1

[0041] 1000 parts by mass of purified terephthalic acid and 400 parts by mass of diol are added to the pulping tank, the diol is preferably ethylene glycol, and then 0.05 parts by mass of esterification is added to the reaction tank Catalyst sodium acetate, 0.5 parts by mass of polycondensation catalyst antimony trioxide and 0.05 parts by mass of stabilizer trimethyl phosphate, start the mixer, beating at a speed of 50-100 revolutions / min for 30 minutes, and then heating and heating to 245°C~ Carry out the esterification reaction at 250°C for 2.5 to 3.0 hours, and when the effluent amount of the esterification reaction reaches more than 95% of the theoretical effluent amount, the esterification reaction ends, and a post-esterification reaction slurry is obtained;

[0042] After the end of the esterification reaction, the slurry after the esterification reaction is transferred to the polycondensation reactor, and the temperature of the slurry after the esterification reaction is co...

Embodiment 2

[0044] 500 parts by mass of purified terephthalic acid and 200 parts by mass of ethylene glycol were added to the pulping tank, and then 0.03 parts by mass of the esterification catalyst magnesium acetate and 0.1 parts by mass of the polycondensation catalyst were added to the reaction tank. Antimony glycol and 0.1 parts by mass of stabilizer triphenyl phosphate, then start the mixer, beating at a speed of 50-100 revolutions per minute for 20 minutes, then heating and then raising the temperature to 255℃~260℃ for esterification reaction 3.5~4 When the effluent amount of the esterification reaction reaches more than 95% of the theoretical effluent amount, the esterification reaction ends, and a slurry after the esterification reaction is obtained;

[0045] After the end of the esterification reaction, the slurry after the esterification reaction is transferred to the polycondensation reactor, and the temperature of the slurry after the esterification reaction is continuously increa...

Embodiment 3

[0047] 800 parts by mass of purified terephthalic acid and 310 parts by mass of ethylene glycol were added to the pulping tank, and then 0.01 parts by mass of esterification catalyst cobalt acetate and 0.2 parts by mass of polycondensation catalyst ethyl were added to the reaction tank. A mixture of antimony diol and antimony trioxide and 0.1 parts by mass of stabilizer phosphoric acid, then start the mixer, beating at a speed of 50-100 revolutions per minute for 20 minutes, then heating and then raising to 250°C to 255°C for esterification React for 3.0 to 3.5 hours, when the effluent amount of the esterification reaction reaches more than 95% of the theoretical effluent amount, the esterification reaction ends, and a slurry after the esterification reaction is obtained;

[0048] After the esterification reaction is completed, transfer the esterification slurry to the polycondensation reactor, continue to increase the temperature of the esterification slurry to 275°C to 278°C, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com