Flame retardant nonwoven needle-punched exhibition carpet

A non-woven acupuncture and exhibition blanket technology, which is applied in the manufacture of fire-retardant and flame-retardant filaments, melt spinning, textiles and paper making, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

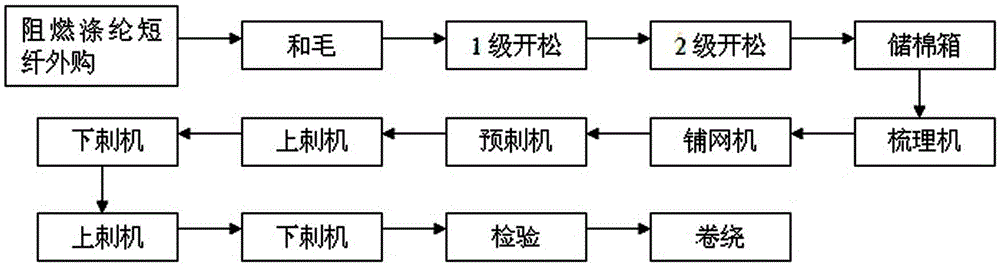

[0031] A flame-retardant non-woven needle-punched exhibition blanket, comprising colored polyester staple fibers, which is spun into a flame-retardant gray fabric by non-woven needle-punched equipment, and then heat-set through an oven to obtain a flame-retardant non-woven needle-punched exhibition blanket; wherein:

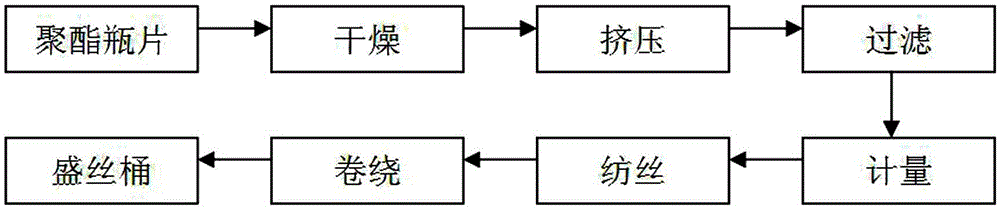

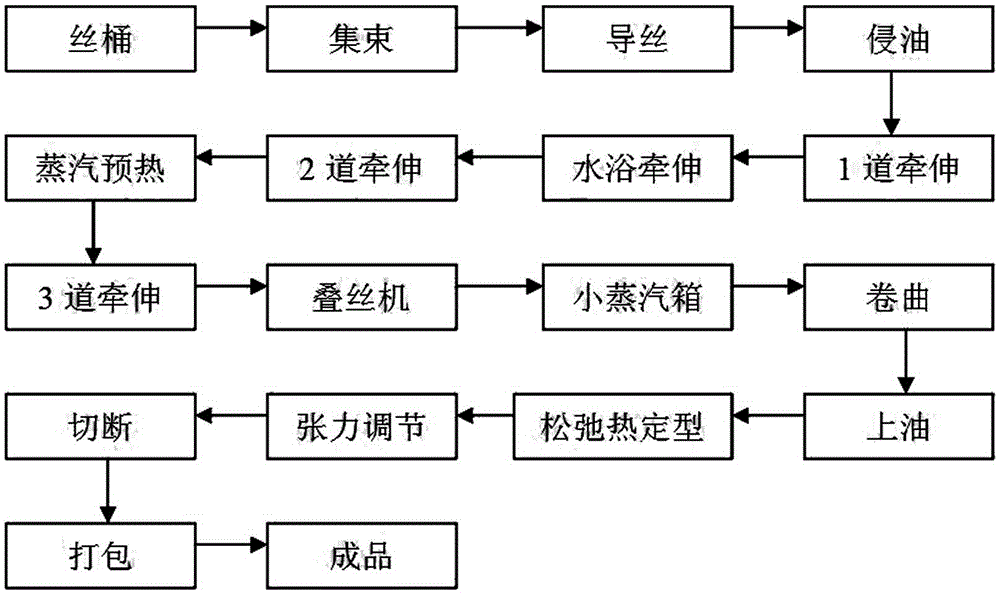

[0032] 1. Production of flame retardant polyester staple fiber:

[0033] (1) Raw materials used in fiber processing:

[0034] 1. 80% of copolymerized primary phosphorus-based flame-retardant polyester chips, 68% of copolymerized or blended recycled phosphorus-based flame-retardant polyester foam material, and 7% of masterbatch;

[0035] Melt spinning process: the spinning process temperature is 260°C.

[0036] 2. 85% recycled polyester bottle flakes, 90% recycled polyester foam, and 9% blended flame retardant masterbatch;

[0037] The blended flame retardant masterbatch includes phosphorus-based flame retardants such as 2-carboxyethyl phosphoric acid, 2-carboxy...

Embodiment 2

[0065] A flame-retardant non-woven needle-punched exhibition blanket as described in Example 1, wherein:

[0066] 1. Production of flame retardant polyester staple fiber:

[0067] (1) Raw materials used in fiber processing:

[0068] 1. 98% of copolymerized primary phosphorus-based flame-retardant polyester chips, 50% of copolymerized or blended recycled phosphorus-based flame-retardant polyester foam material, and 8% of masterbatch;

[0069] Melt spinning process: the spinning process temperature is 275°C.

[0070] 2. 70% recycled polyester bottle flakes, 90% recycled polyester foam, 2% blended flame retardant masterbatch;

[0071] The blended flame retardant masterbatch includes phosphorus-based flame retardants such as 2-carboxyethyl phosphoric acid, 2-carboxyethyl methyl phosphate and 2-carboxyethyl methyl phosphoric acid and color master batches; the color masterbatch The mass percentage of grains is 2-15%;

[0072] Melt spinning process: spinning temperature is 260°C....

Embodiment 3

[0074] A flame-retardant non-woven needle-punched exhibition blanket as described in Example 1, wherein:

[0075] 1. Production of flame retardant polyester staple fiber:

[0076] (1) Raw materials used in fiber processing:

[0077] 1. 90% of copolymerized primary phosphorus-based flame-retardant polyester slices, 45% of copolymerized or blended recycled phosphorus-based flame-retardant polyester foam materials, and 10% of masterbatch;

[0078] Melt spinning process: the spinning process temperature is 240°C.

[0079] 2. 50% recycled polyester bottle flakes, 96% recycled polyester foam, 10% blended flame retardant masterbatch;

[0080] The blended flame retardant masterbatch includes phosphorus-based flame retardants such as 2-carboxyethyl phosphoric acid, 2-carboxyethyl methyl phosphate and 2-carboxyethyl methyl phosphoric acid and color master batches; the color masterbatch The mass percentage of grains is 2-15%;

[0081] Melt spinning process: spinning temperature is 29...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com