Nylon resin and preparation method thereof

A nylon resin, polymerized monomer technology, applied in the field of resin, can solve the problems of affecting mechanical properties, low resin viscosity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The embodiment of the present invention discloses a kind of preparation method of nylon resin, comprises the following steps:

[0025] Mix the polymerized monomer, catalyst, reactive flame retardant, and char-forming agent for polycondensation reaction to obtain nylon resin;

[0026] The polymerized monomer includes one or more of compounds containing both amino and carboxyl groups and lactams;

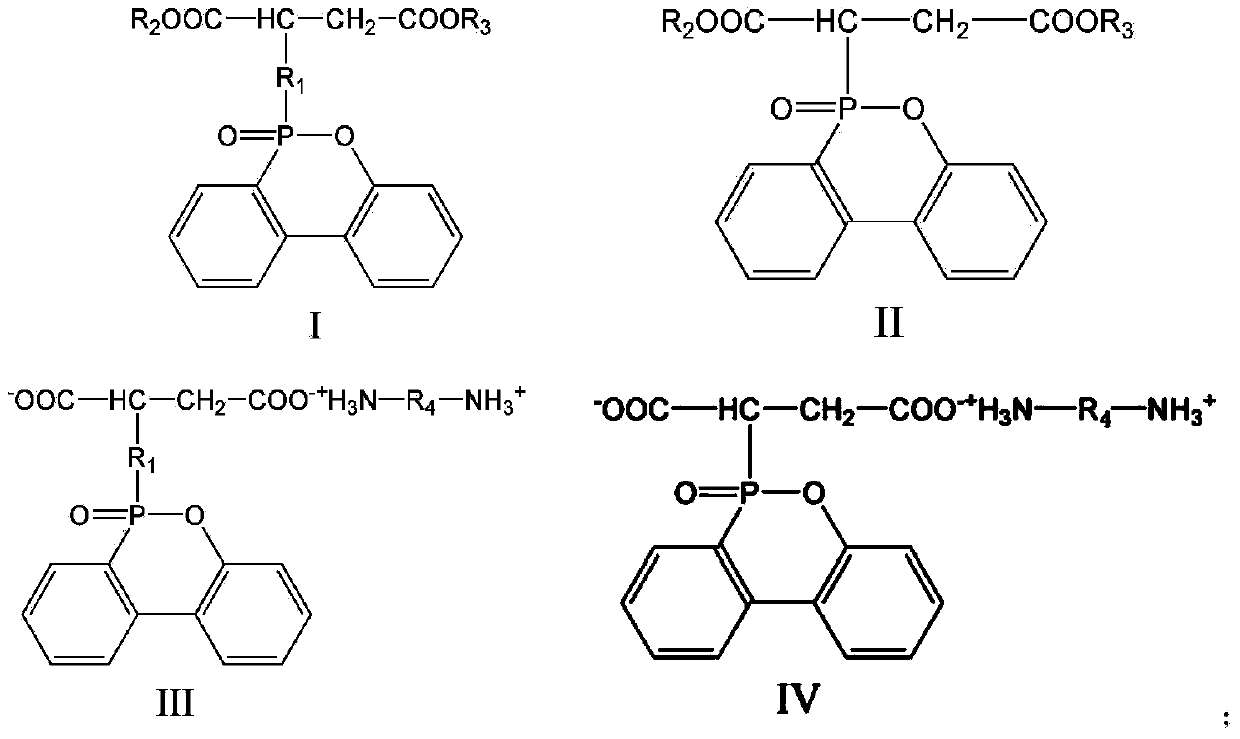

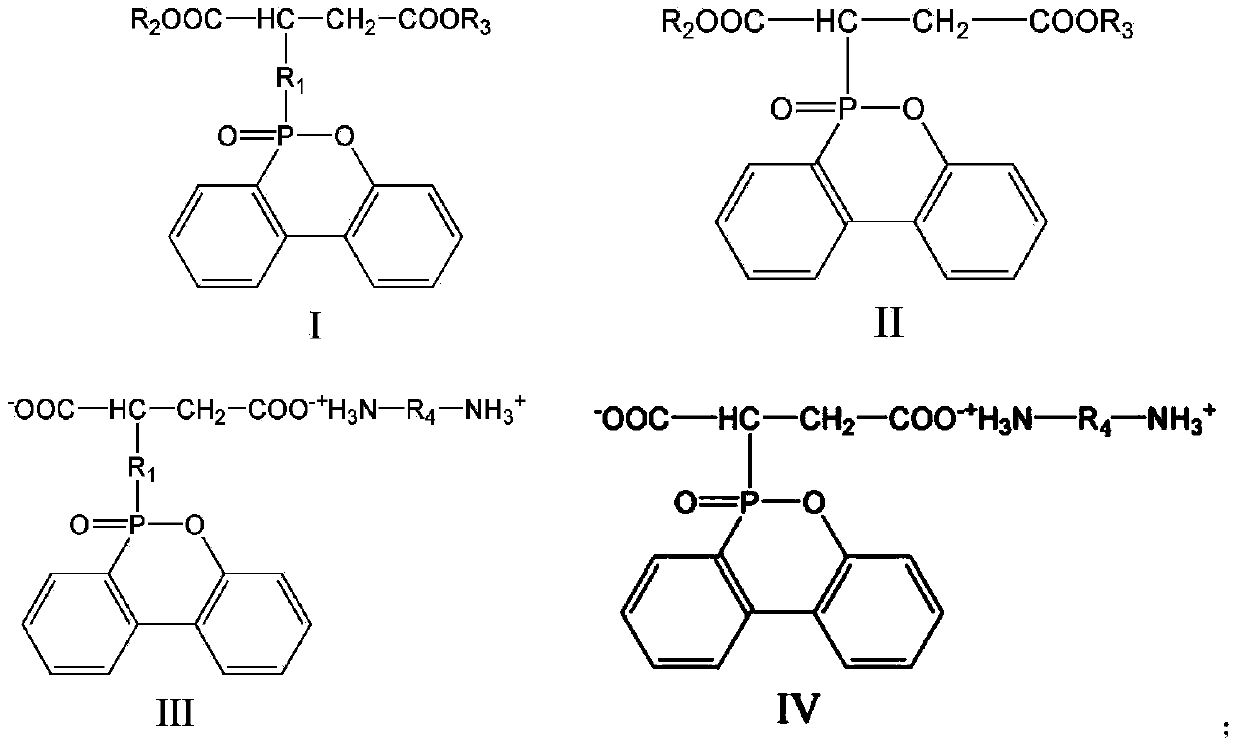

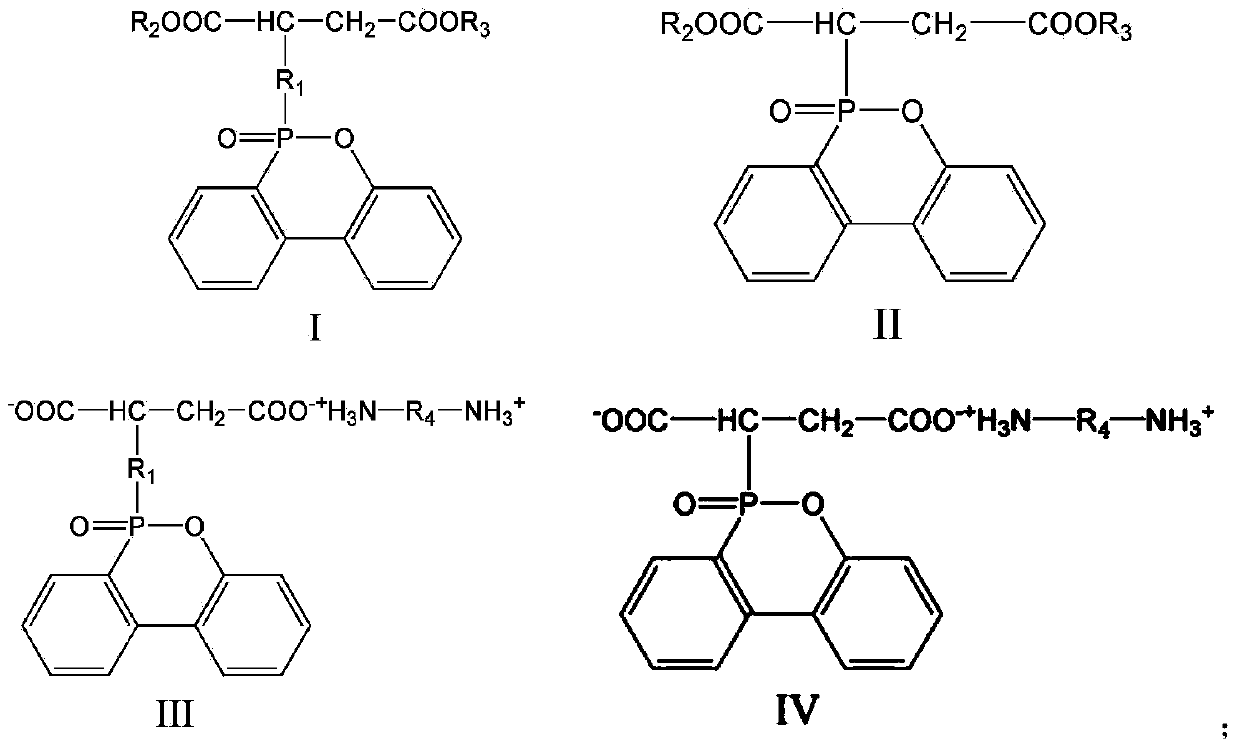

[0027] The reactive flame retardant is one or more of the compounds with the structures of formulas (I) to (IV):

[0028]

[0029] where R 1 is an alkylene group of 1 to 4 carbon atoms, R 2 and R 3 Any selected from -H, -CH 2 COOH,-CH 2 CH 2 COOH,-CH 2 CH 2 CH 2 COOH or an alkyl group with 1 to 4 carbon atoms, preferably R 2 and R 3 not simultaneously an alkyl group of 1 to 18 carbon atoms, R 4 is an alkylene or arylene group of 1 to 12 carbon atoms.

[0030] In the present invention, the nylon resin is prepared from polymerized monomers, catalysts, reactive fla...

Embodiment 1~7

[0043] (1) The polymer monomer, catalyst, reactive flame retardant and char-forming agent are formulated into materials in a certain proportion. See Table 1 for details.

[0044] (2) Put the prepared materials into the high-pressure reaction kettle, close the feeding cover tightly, connect the cooling water of the jacket of the polymerization kettle; pressurize the kettle with high-purity nitrogen to make the pressure in the kettle positive, open the pressure relief valve to evacuate the kettle Reduce the pressure to negative pressure, do this several times, and finally pass high-purity nitrogen to normal pressure, and then close the exhaust valve tightly.

[0045] (3) Heating the high-pressure reactor filled with materials, when the temperature reaches 200°C-280°C and the pressure of the kettle is 0.2Mpa-2.0Mpa, the reaction time is 1h, 3h, 5h, 6h, 8h, 10h, 12h.

[0046] (4) Open the pressure relief valve to reduce the pressure of the kettle to normal pressure, and then the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com