A kind of modified nano silicon dioxide, its preparation method and application

A nano-silica and modification technology, which is applied in the field of modified nano-silica, can solve the problems of poor dispersion stability, restriction, and reduction of cross-linking density, and achieve the effect of easy dispersion, small influence, and increased cross-linking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

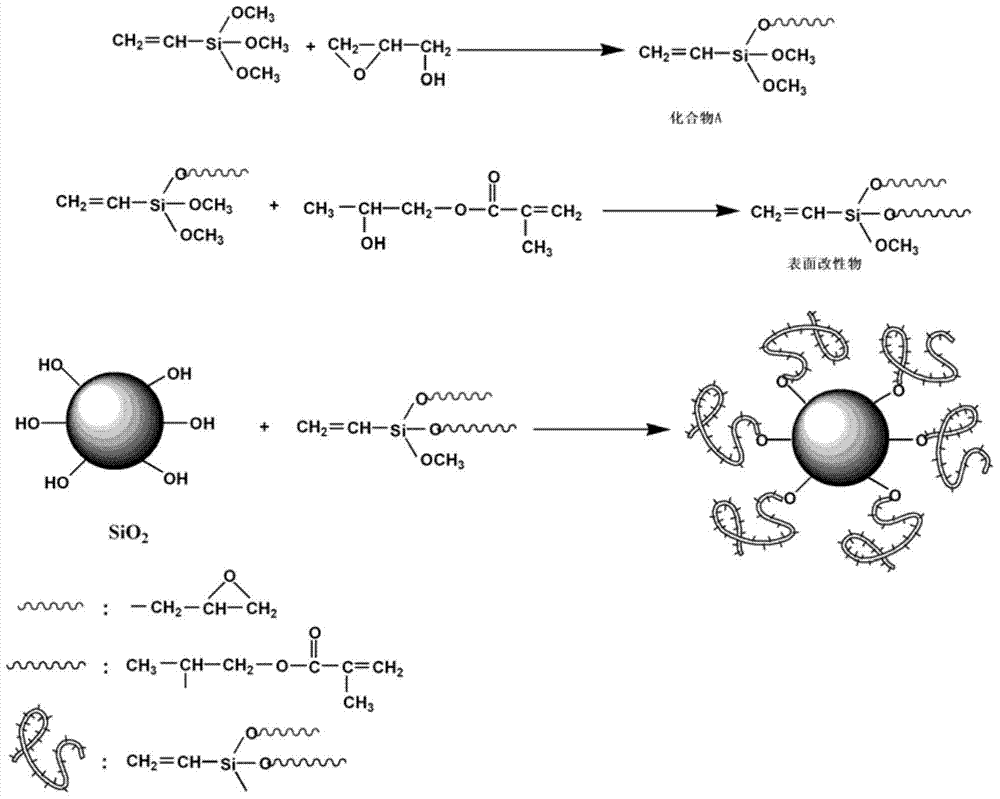

[0050] This embodiment provides a modified nano-silica with double bonds and epoxy groups grafted on the surface and a preparation method thereof.

[0051] (1) Add 500g of vinyltrimethoxysilane, 249.87g of glycidol, 0.38g of stannous chloride, and 0.75g of hydroquinone into a three-necked reaction flask, match with a distillation device, stir, heat up to 145°C, and react for 3.5 hours , evacuated, methanol was removed, and cooled to obtain Compound A.

[0052](2), add 729.43g hydroxypropyl methacrylate, 0.37g stannous chloride, 0.68g hydroquinone to the compound A obtained in step (1), stir, heat up to 150°C, react for 4 hours, pump Vacuum to remove methanol and cool to obtain surface modified products.

[0053] (3), add 7g BYK2000, 300g nano silicon dioxide to 1500g xylene at a stirring speed of 2800r / min, after adding, continue to stir and disperse for 3 hours, then put the dispersion into the grinder, grind and disperse for 4 hours, grind until the powder D50≤100nm, to ob...

Embodiment 2

[0057] This embodiment provides a modified nano-silica with double bonds and epoxy groups grafted on the surface and a preparation method thereof.

[0058] (1) Add 296g of vinyltrimethoxysilane, 170.12g of glycidol, 0.43g of stannous chloride, and 0.50g of hydroquinone into a three-necked reaction flask, match with a distillation device, stir, heat up to 153°C, and react for 4 hours , evacuated, methanol was removed, and cooled to obtain compound A.

[0059] (2), add 531.73g hydroxypropyl methacrylate, 0.37g stannous chloride, 0.65g hydroquinone to compound A prepared in step (1), stir, heat up to 153°C, and react for 3 hours , vacuumize, remove methanol, and cool to obtain surface modified products.

[0060] (3), add 12g BYK2000, 460g nano silicon dioxide to 1533g xylene at a stirring speed of 3000r / min, after adding, continue to stir and disperse for 2 hours, then put the dispersion into the grinder, grind and disperse for 3.5 Hours, grind to nano powder D50≤100nm, obtain ...

Embodiment 3

[0064] This embodiment provides a modified nano-silica with double bonds and epoxy groups grafted on the surface and a preparation method thereof.

[0065] (1) Add 283g of vinyltrimethoxysilane, 212g of glycidol, 0.25g of stannous chloride, and 0.49g of hydroquinone into a three-necked reaction flask, match with a distillation device, stir, heat up to 156°C, and react for 4 hours. Vacuumize, remove methanol, and cool to obtain compound A.

[0066] (2) Add 412.87g hydroxypropyl methacrylate, 0.2g stannous chloride, and 0.4g hydroquinone to the reaction flask of compound A, stir, heat up to 156°C, react for 4 hours, and vacuumize. Removal of methanol and cooling to obtain surface modified products.

[0067] (3), add 18.5g BYK2000, 530g nano-silica to 1892.8g xylene at a stirring speed of 3500r / min, after adding, continue to stir and disperse for 3.6 hours, then put the dispersion into the grinder, grind Disperse for 5 hours, grind until the nano powder D50≤100nm, and obtain th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com