Anti-microwave radiation flax yarn and production process thereof

A technology of microwave radiation and production technology, applied in the field of clothing and home textile fabrics, can solve problems such as being unsuitable for production, and achieve the effects of good whiteness, soft hand feeling, and low degree of fiber damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Implementation column 1

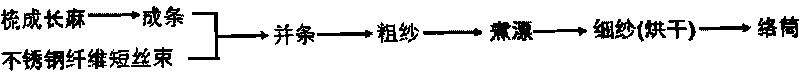

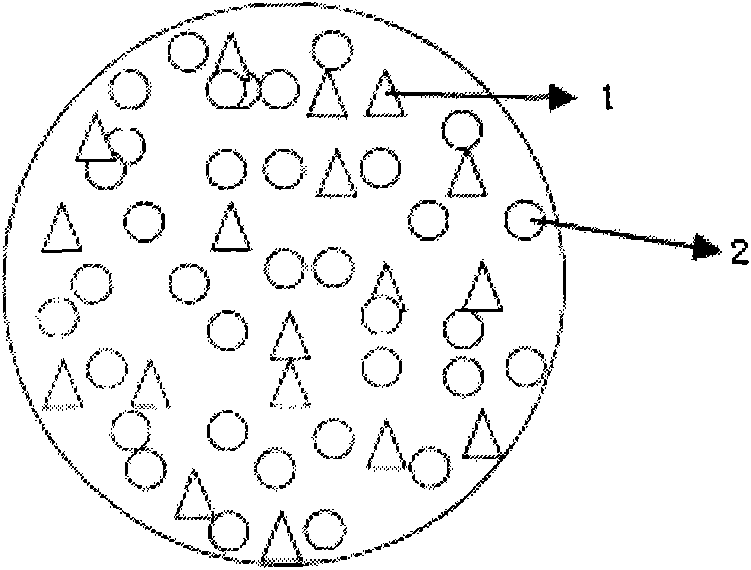

[0022] see figure 1 , the long flax fibers are combed into slivers with a certain amount through the slitting process, and at the same time, the prepared slivers are subjected to three drawing processes: the flax fibers are continuously drawn in the first drawing to the third drawing Carry out drafting and merging, and mix stainless steel metal fibers in the fourth drawing process, the diameter of the stainless steel metal fibers is 6-8 μm, the steel number is 304 or 316L stainless steel fiber bundles, the stainless steel metal fibers and flax fibers After three drawing frames: the fourth drawing process and the fifth drawing process twice, so as to ensure that the stainless steel metal fiber can be fully and evenly mixed with the flax long fiber, and the stainless steel metal fiber accounts for 5% of the blended yarn mass, The final drawing weight is 19.52g / 5m.

[0023] The obtained mixed sliver is made into a roving through the roving proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com