Wash-wear nonwoven fabric capable of selectively blocking ultraviolet rays

A non-woven fabric and ultraviolet technology, applied in textiles and papermaking, fiber type, fiber treatment, etc., can solve the problems of affecting material weight, high addition amount, etc., and achieve good washing resistance, good flexibility, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The preparation method of the above-mentioned selectively blocking ultraviolet non-woven fabric generally comprises the following steps:

[0018] The preparation of the mixed dispersion of large-scale graphene oxide and water-based polymer resin can be directly mixed uniformly by 0.2-0.5 parts by weight of large-scale graphene oxide, 10-30 parts by weight of water-based polymer resin and 100 parts by weight of deionized water can also be obtained by the following steps:

[0019] (1) Dissolving 0.2-0.5 parts by weight of large-scale graphene oxide raw material in 50 parts by weight of deionized water to obtain a large-scale graphene oxide solution;

[0020] (2) Mix 20-30 parts by weight of water-based polymer resin with 50 parts by weight of deionized water, and stir at a temperature of 20-60 degrees Celsius for 1-5 hours to obtain a water-based polymer resin dispersion;

[0021] (3) Mix the large-scale graphene oxide solution and the aqueous polymer resin dispersion at...

Embodiment 1

[0025] (1) Dissolve 0.34g of large-scale graphene oxide raw material in 50g of deionized water to obtain large-scale graphene oxide solution;

[0026] (2) Mix 20 g of acrylic resin with 50 g of deionized water in parts by weight, and stir for 3 hours at a temperature of 30 degrees Celsius to obtain an aqueous dispersion of acrylic resin;

[0027] (3) Mix the large-scale graphene oxide solution and the acrylic resin aqueous dispersion at a mass ratio of 1:1, and stir at a temperature of 30 degrees Celsius for 12 hours to obtain a coating solution containing large-scale graphene oxide;

[0028] (4) Spray the coating solution containing large pieces of graphene oxide on the surface of the black polypropylene non-woven fabric by spraying, roll the surface coating of the non-woven fabric evenly with a roller, and dry it in an oven. The drying temperature is 80 degrees Celsius, and the drying time is 50 minutes.

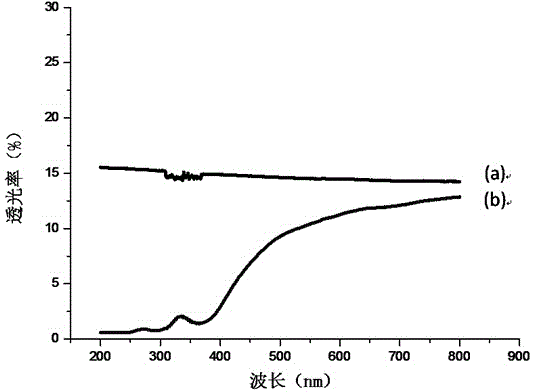

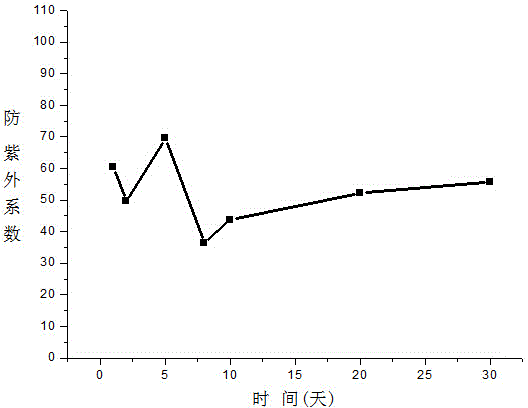

[0029] Through the above steps, the average transmittance of the obt...

Embodiment 2

[0031] (1) Dissolve 0.2g of large-scale graphene oxide raw material in 50g of deionized water to obtain large-scale graphene oxide solution;

[0032] (2) Mix 20 g of acrylic resin in parts by weight with 50 g of deionized water, and stir for 2.5 hours at a temperature of 40 degrees Celsius to obtain an aqueous dispersion of acrylic resin;

[0033] (3) Mix the large-scale graphene oxide solution and the acrylic resin aqueous dispersion at a mass ratio of 1:1, and stir at a temperature of 40 degrees Celsius for 10 hours to obtain a coating solution containing large-scale graphene oxide;

[0034] (4) Spray the coating solution containing large pieces of graphene oxide on the surface of the black acrylic non-woven fabric by spraying, roll the surface coating of the non-woven fabric evenly with a roller, and dry it in an oven. The temperature is 80 degrees Celsius, and the drying time is 50 minutes.

[0035] Through the above steps, the average transmittance of the obtained non-wo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com