Preparation method for graphene with three-dimensional porous structure

A three-dimensional porous and graphene technology, applied in the field of materials, can solve the problems of low Coulombic efficiency, fast attenuation, and low specific surface area, and achieve the effect of firm pore structure, avoiding toxic chemical reagents and graphene agglomeration, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Firstly, the improved Hummers method was used to prepare graphite oxide; then, 90 mL of deionized water and 9 mL of styrene monomer were added to the three-neck flask, and the air in the solution was continuously vented with nitrogen, and magnetically stirred for 30 minutes; the temperature was gradually raised to 70 ℃, add 0.03g / mL potassium persulfate 10mL; continue to react for 24h, centrifuge and dry to obtain polystyrene pellets;

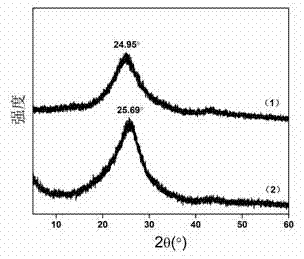

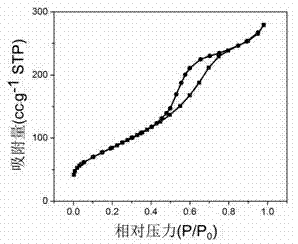

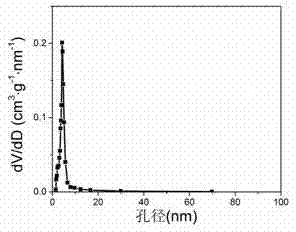

[0027] (2) Ultrasonically exfoliate the graphite oxide prepared above into graphene oxide at room temperature, the concentration is 5g / L, polystyrene pellets and graphene oxide are added to the above solution at a mass ratio of 3:1 and mixed by ultrasonic for 2 hours to form colloidal particles , adjust pH=8, polystyrene nanospheres are evenly dispersed in graphene oxide, after suction filtration and drying, thermally decompose polystyrene beads in a nitrogen environment and thermally reduce graphene oxide to obtain a three-dimensiona...

Embodiment 2

[0029] No polystyrene pellet template was added as a comparative test, and graphene was prepared by thermal reduction method using the same steps. First, the improved Hummers method was used to prepare graphite oxide, and then the graphite oxide was ultrasonically exfoliated into graphene oxide at room temperature with a concentration of 5g / L, and then ultrasonicated for 2h to adjust the pH to 8. After suction filtration and drying, it is calcined at a high temperature in a nitrogen atmosphere, and the graphene oxide is thermally reduced to obtain graphene.

[0030] In the experiment, we compared the effects of not using template method and using template method on graphene specific surface area, pore size and specific capacitance, and found that after using template method, graphene specific surface area and specific capacitance were significantly improved, and the average pore size distribution also occurred. changed a lot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com