Method for manufacturing nano tin dioxide

A technology of nano-tin dioxide and tin salt, applied in the direction of tin oxide, nanotechnology, nanotechnology, etc., can solve the problems of complex operation, high production cost, unsatisfactory product yield, etc., and achieve simple process, low cost and low price cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

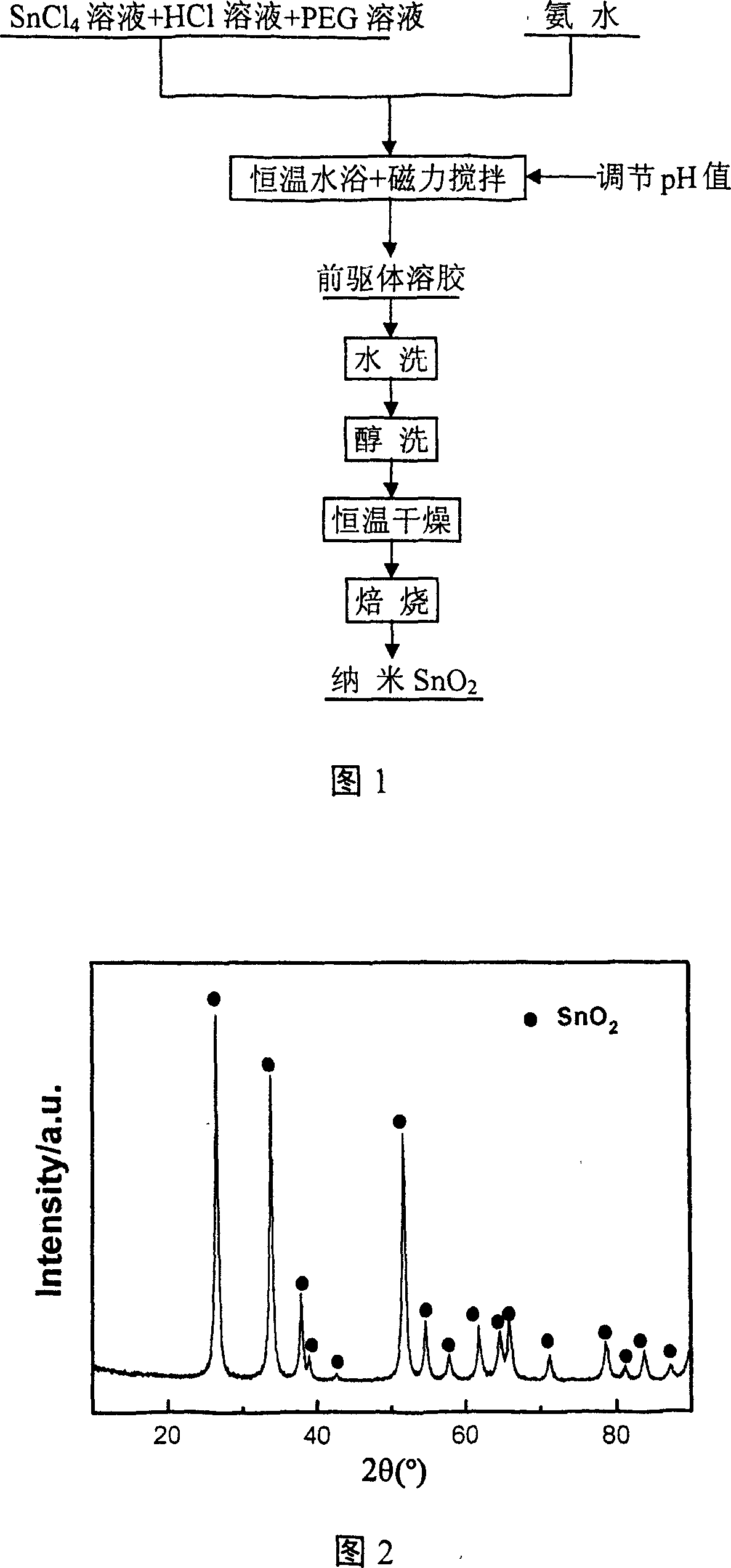

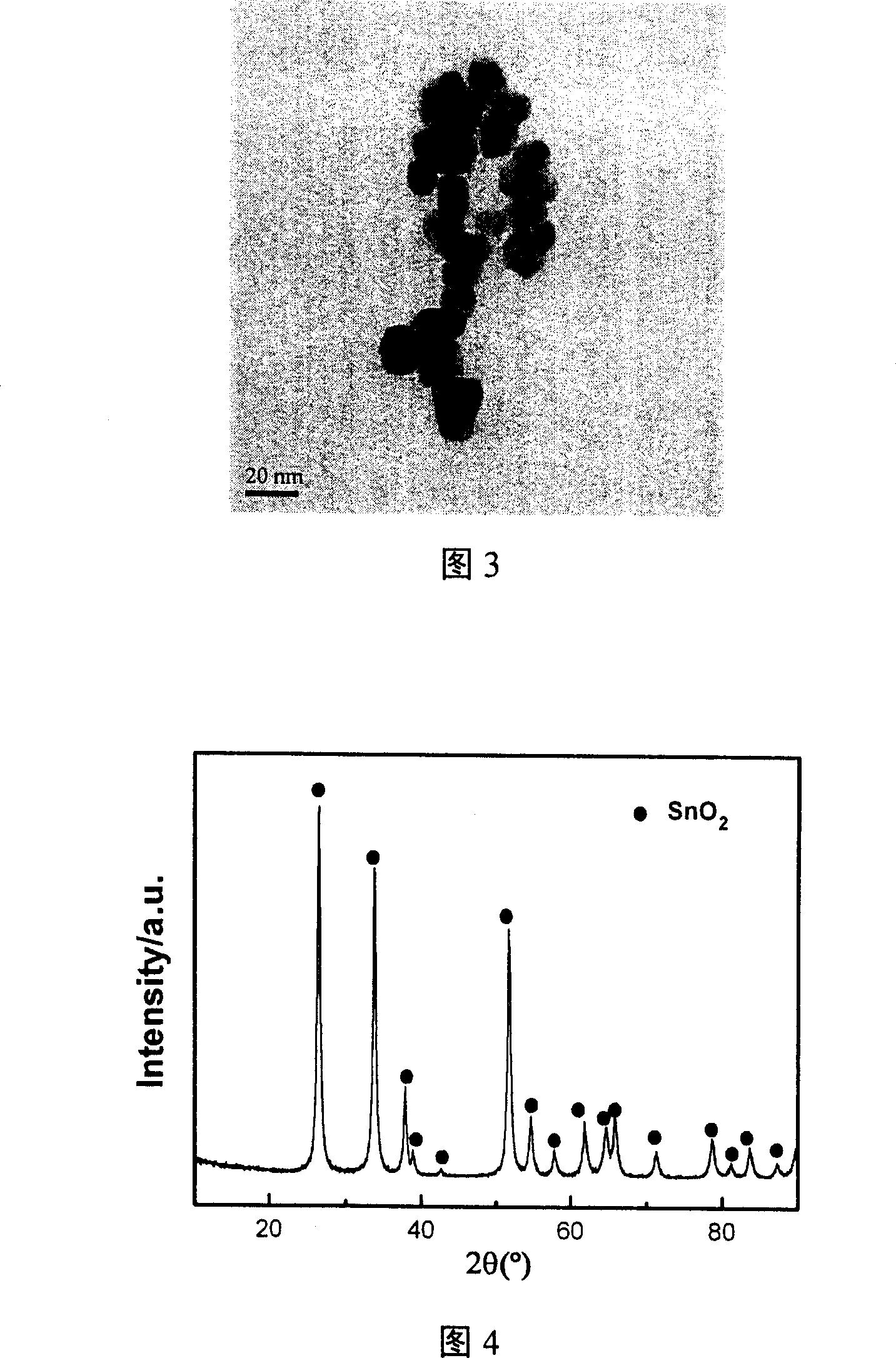

[0017] Weigh SnCl 4 ·5H 2 O 7.01g, made into 200ml of 0.1mol / L solution, and adding 1gPEG4000 and 10ml of 0.1mol / L HCl solution therein; configuring 500ml of 1mol / L ammonia solution; placing the configured tin tetrachloride solution in a magnetic Preheat at 30°C for 10 minutes on a constant temperature stirrer, slowly add the prepared ammonia solution into the tin tetrachloride solution with an alkaline burette, and control the pH value to 3 with a pH meter, then stop adding and continue stirring at a medium speed 15min; the resulting precursor sol was washed 8 times with deionized water during vacuum filtration, washed 2 times with ultrasonic alcohol, and then dried in a blast drying oven at 60°C. Roasting for 2h, the light yellow nano-SnO 2 The XRD pattern of the product is shown in Figure 2, and the TEM photo is shown in Figure 3. The particle size is about 15-17nm, and it can be seen that the grains are evenly distributed and there is no agglomeration.

Embodiment 2

[0019] Embodiment 2 weighs SnCl 4 ·5H 2 O 35.05g, made into 200ml of 0.5mol / L solution, and adding 5gPEG4000 and 10ml0.1mol / L of HCl solution therein; configuring 500ml of 1mol / L ammonia solution; placing the configured tin tetrachloride solution in a magnetic constant temperature Preheat the stirrer at 30°C for 10 minutes, slowly add the prepared ammonia solution into the tin tetrachloride solution with a basic burette, and control the pH value to 2.5 with a pH meter, then stop the dropwise addition and continue stirring at a medium speed for 15 minutes The resulting precursor sol was washed 8 times with deionized water during vacuum filtration, washed 2 times with ultrasonic alcohol, and then dried in a blast drying oven at 60°C, and the white precursor dry powder obtained was roasted in a muffle furnace at 600°C 2h, that is, light yellow nano-SnO 2 The XRD spectrum of the product is shown in Figure 4, and the particle size is about 17-20nm.

Embodiment 3

[0021] Weigh SnCl 4 ·5H 2 O 14.02g, made into 200ml of 0.2mol / L solution, and adding 2gPEG4000 and 10ml0.1mol / L of HCl solution therein; configure 500ml of 1mol / L ammonia solution; place the configured tin tetrachloride solution in a magnetic Preheat at 30°C for 10 minutes on a constant temperature stirrer, slowly add the prepared ammonia solution into the tin tetrachloride solution with a basic burette, and control the pH value to 3.5 with a pH meter, then stop the dropwise addition and continue stirring at a medium speed 15min; the resulting precursor sol was washed 8 times with deionized water during vacuum filtration, washed 2 times with ultrasonic alcohol, and then dried in a blast drying oven at 60°C. Roasting for 2h, the light yellow nano-SnO 2 The particle size of the product is about 10-15nm, and it can be seen that the grains are evenly distributed and there is no agglomeration.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com