Ultra-low surface roughness polyester base film/composite base film and preparation method thereof

A technology of surface roughness and polyester base film, applied in chemical instruments and methods, other household appliances, synthetic resin layered products, etc., can solve the problem of large roughness of polyester base film and reduce surface roughness of polyester film, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] Preparation of the first part of the surface modification

[0056] 1. Nano slurry preparation:

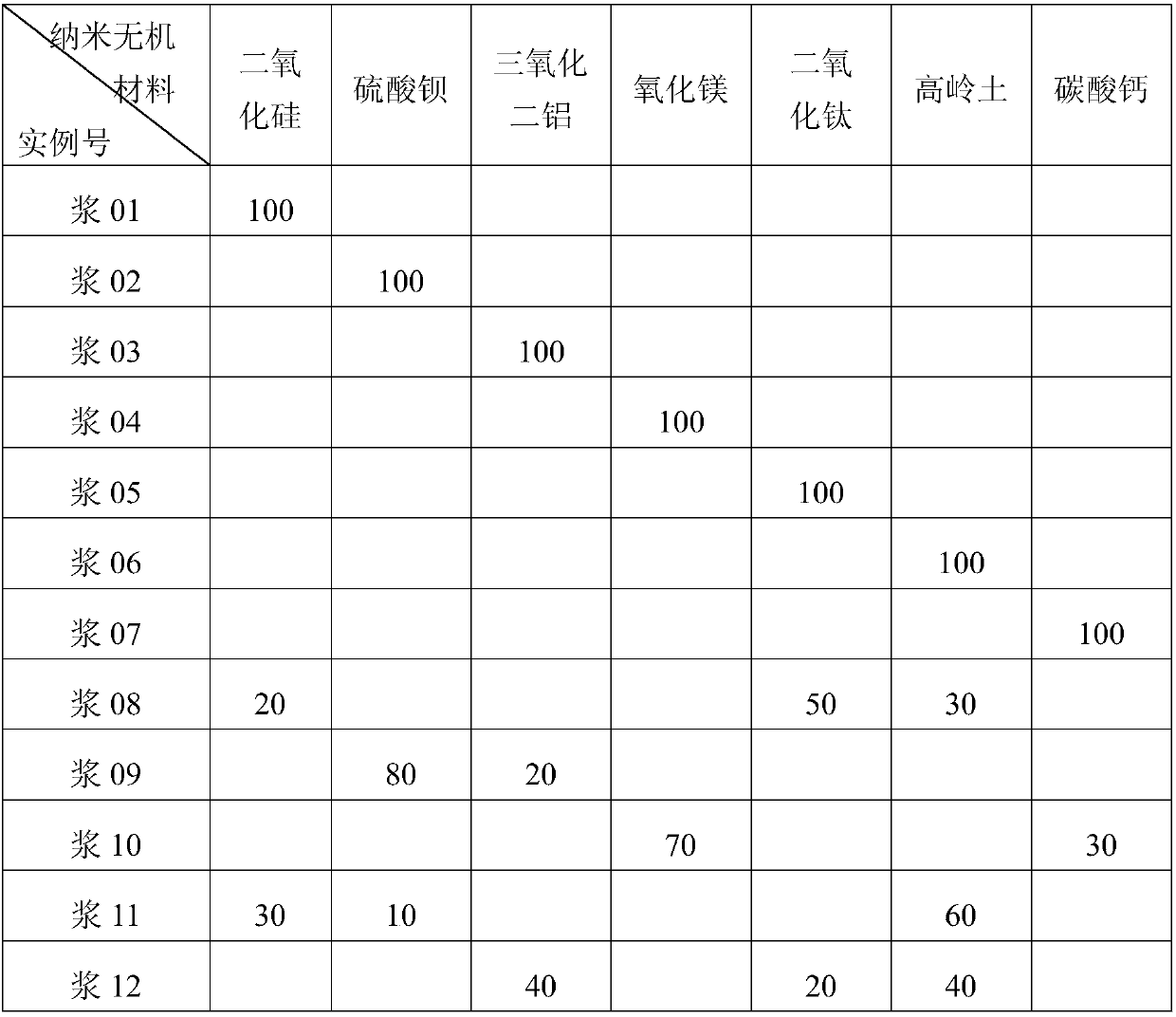

[0057] At room temperature, put 100kg of 50nm to 500nm nano-inorganic materials and 400kg of ethylene glycol into a mixer with ultra-high-speed stirring, and stir evenly to make a nano-slurry for later use. See Table 1 below for the amount of nano-inorganic materials used in the example numbers "Pulp 01-Pulp 12" of the nano-slurries.

[0058] Table 1: Nano-inorganic materials and dosage in nano-slurry (unit: ㎏)

[0059]

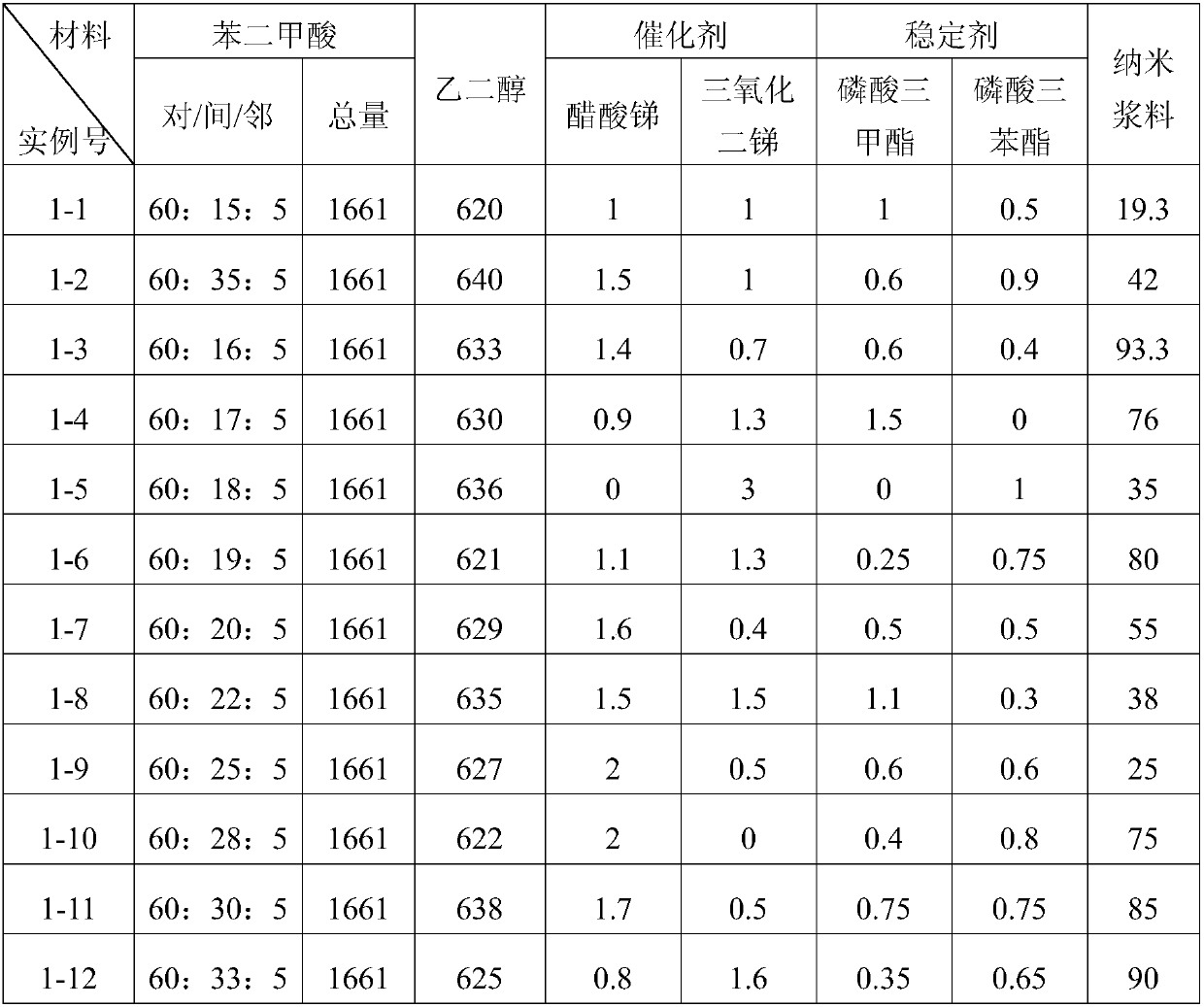

[0060] 2. Preparation of surface modification materials:

[0061] Add 1661kg of phthalic acid, 620~640kg of ethylene glycol, 2~3kg of catalyst, 1~1.5kg of stabilizer into the reactor, fill it with nitrogen, and react after esterification reaction at 230~260℃ for 2~3 hours At the end, keep the reactor at a vacuum of 0.08-0.09MPa while keeping the temperature at 270-290°C for polycondensation reaction. When the resin viscosity is 0.30-0.40dL / g, add 19.3...

Embodiment 4

[0084] An ultra-low surface roughness polyester base film, the ultra-low surface roughness polyester base film is made of a mixture of 40% polyester and 60% surface modifier by mass percentage, extruded and cast after melting and kneading A single-layer film with a thickness of 20 μm and a surface roughness Ra of 15 nm is produced by stretching the sheet, vertical and horizontal biaxial stretching, and heat setting.

[0085] The polyester has an intrinsic viscosity of 0.62-0.68dL / g, a melting point of 255-265°C, and a molecular weight of 20,000-30,000;

[0086] The surface modifier is composed of 0.2% nano-inorganic material and 99.8% copolyester with a molecular weight in the range of 20,000 to 30,000. The copolyester is obtained by polycondensation of phthalic acid and ethylene glycol. The viscosity of the surface modifier is within the range of 0.60 to 0.75dL / g;

[0087] The nano-inorganic material is one or both of nano-silicon dioxide, nano-barium sulfate, nano-alumina, ...

Embodiment 5

[0089] An ultra-low surface roughness polyester base film, the ultra-low surface roughness polyester base film is made of a mixture of 80% polyester and 20% surface modifying material, which is melted and kneaded, extruded and cast A single-layer film with a thickness of 250 μm and a surface roughness Ra of 35 nm is produced by stretching the sheet, vertical and horizontal biaxial stretching, and heat setting.

[0090] The polyester has an intrinsic viscosity of 0.62-0.68dL / g, a melting point of 255-265°C, and a molecular weight of 20,000-30,000;

[0091] The surface modifier is composed of 1% nano-inorganic material and 99% copolyester with a molecular weight in the range of 20,000 to 30,000. The copolyester is obtained by polycondensation of phthalic acid and ethylene glycol. The viscosity of the surface modifier is within the range of 0.60 to 0.75dL / g;

[0092] The nano-inorganic material is one or both of nano-silicon dioxide, nano-barium sulfate, nano-alumina, nano-magne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com