Completely biodegradable hydrophobic material and its prepn

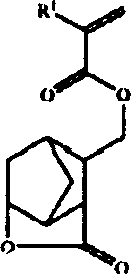

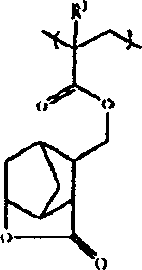

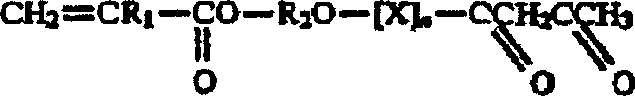

A biodegradable material and a biodegradable technology are applied in the field of starch-based hydrophobic completely biodegradable materials and their preparation, which can solve the problems of no functional group that can be reacted with hydroxyl again, and no active reaction center of polylactone that can be reacted with hydroxyl. , to achieve the effect of improving elongation at break, hydrophobic performance and compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Weigh 45Kg of cornstarch, 178820Kg of polyvinyl alcohol, 2Kg of polycaprolactone, 15Kg of glycerin, 0.4Kg of borax, 3Kg of EVA, 0.4Kg of stearic acid, and 1Kg of succinic acid into the high-speed mixer in sequence, stir for 5 minutes, and discharge.

[0074] Extrude the above-mentioned mixed material, the barrel temperature of the extruder is: 130°C, 150°C, 160°C, 170°C, 180°C, 180°C, 190°C, 190°C, the die head temperature is 180°C, the screw speed 100rpm. Add ε-caprolactone monomer 1.5kg, butyl methacrylate monomer 0.01kg, catalyst hydroxyethyl titanate tetraacrylate 0.005kg, α-hydroxycyclohexyl benzophenone to the side feeding port of the extruder 0.01kg, the side screw speed is about 10rpm, the material in the main feeding port and the material in the side feeding port are used up almost at the same time. The film product obtained by extrusion blow molding is tested by the method specified in GB1040-1979: the tensile strength of the product is 16.1MPa, and the elong...

Embodiment 2

[0076] Weigh 50Kg of cornstarch, 20Kg of PVA 1788, 2Kg of polylactic acid, 15Kg of glycerin, 0.4Kg of borax, 3Kg of EVA, 0.4Kg of stearic acid, and 1Kg of succinic anhydride, and add them into the high-speed mixer in sequence, stir for 5 minutes, and discharge.

[0077] Extrude the above-mentioned mixed material, the barrel temperature of the extruder is: 130°C, 150°C, 160°C, 170°C, 180°C, 180°C, 190°C, 190°C, the die head temperature is 180°C, the screw speed 100rpm. Add 1.5kg of lactide monomer, 0.01kg of butyl methacrylate monomer, 0.005kg of catalyst methyl titanate tetraacrylate, and 0.01kg of azobisisobutyronitrile at the side feeding port of the extruder, The screw speed is about 10rpm, and the material in the main feeding port and the side feeding port are used up almost simultaneously. The extruded sheet product is tested by the method specified in GB1040-1979: the tensile strength of the product is 17.3MPa, and the elongation at break is 140%; the method specified b...

Embodiment 3

[0079] Weigh 45Kg of corn starch, 1799 20Kg of polyvinyl alcohol, 2Kg of poly 3-hydroxybutyl ester (PHB), 18Kg of glycerin, 0.3Kg of borax, 3 Kg of EVA, 0.5Kg of stearic acid, 1Kg of adipic acid, and add them into the high-speed mixer in turn , start stirring for 5 minutes, and discharge.

[0080] Extrude the above-mentioned mixed material, the barrel temperature of the extruder is: 130°C, 150°C, 160°C, 170°C, 180°C, 180°C, 190°C, 190°C, the die head temperature is 180°C, the screw speed At 100rpm, add lactide monomer 0.75kg, ε-caprolactone monomer 0.75kg, butyl methacrylate monomer 0.01kg, catalyst stannous octoate 0.005kg, 2 , 0.01kg of 2-dimethoxyl-2-phenylacetophenone, the side screw speed is about 10rpm, the material in the main feeding port and the material in the side feeding port are used up almost simultaneously. Extrude the product, and use the method specified in GB1040-1979 to test: the tensile strength of the product is 15.7MPa, and the elongation at break is 120...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com