Automatic bolt spreading machine

A glue coating machine and bolt technology, which is applied in the coating, the device for coating liquid on the surface, etc., can solve the problems of uneven coating of the glue layer and low production efficiency, and achieve high production efficiency and convenient workpiece picking and placement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

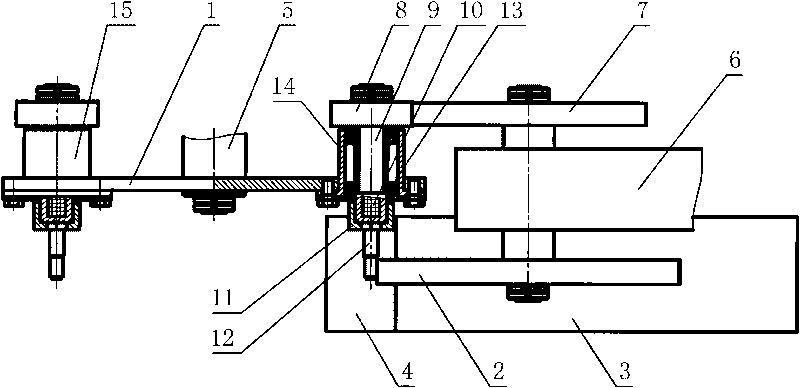

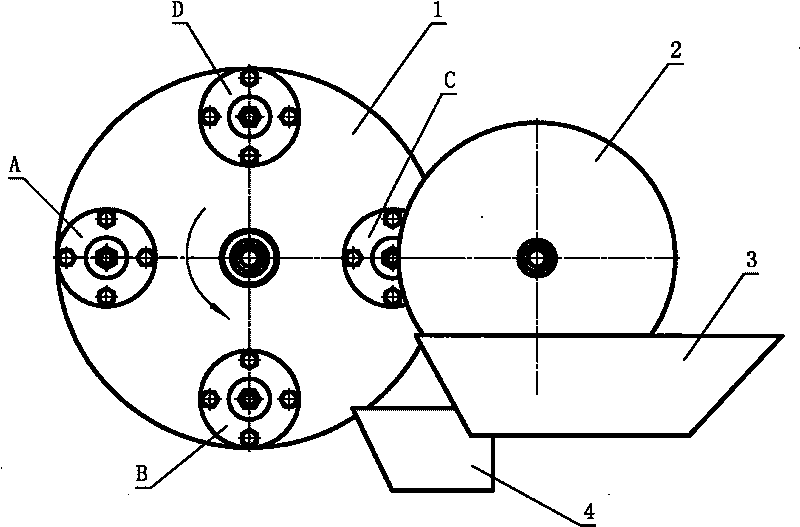

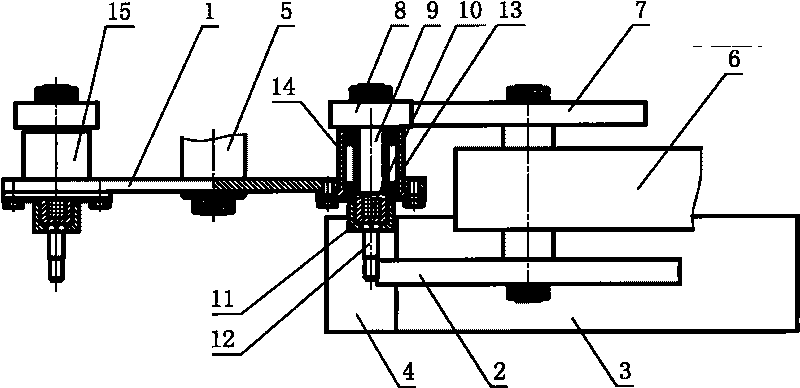

[0014] refer to figure 1 with figure 2 , a kind of bolt automatic gluing machine, comprises frame, gluing wheel 2 and transmission device 6, and described gluing wheel 2 and transmission device 6 are installed on the frame, and the output shaft of described transmission device and described gluing device The wheel 2 is connected, and the lower part of the gluing wheel 2 extends into the glue storage tray 3. The automatic bolt gluing machine also includes a turntable 1, and there are at least two plates around the turntable 1 for clamping and gluing. The electromagnetic chuck 15 of the bolt, the tail end of the electromagnetic chuck 15 is fixedly equipped with a passive drive wheel 8, the passive drive wheel 8 is linked with the active drive wheel 7, and the output of the active drive wheel 7 and the transmission device 6 The shaft is connected, and the position to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com