Aramid fiber polymer coated lithium ion battery membrane and preparation method thereof

A lithium-ion battery and polymer technology, applied in secondary batteries, battery pack components, circuits, etc., can solve problems affecting the wettability of electrolyte and separator, deterioration of heat resistance and mechanical properties, recycling and environmental pollution and other problems, to achieve the effect of convenient continuous production, improved wettability and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

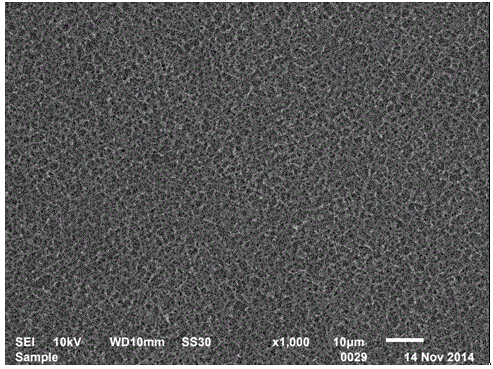

[0042] Weigh 2kg of DMAC, add 0.1kg of sodium polyacrylate, stir until completely dissolved, add 4.4kg of meta-aramid polymer to the above solution, the content of aramid is 10%, the molecular weight of aramid is 80,000-100,000, stir After uniformity, add 3.35kg of isopropanol and 0.05kg of vinylpyrrolidone and vinyl acetate (PVP-VA) copolymerized adhesive sequentially while stirring, and disperse evenly to prepare aramid fiber slurry; select corona polypropylene with a thickness of 16μm The base film has a porosity of 42%. The aramid fiber slurry is coated on one side of the base film by gravure coating, and the coating speed is 15m / min. Pre-solidified for 10s in an environment with a humidity of 90%, washed with water for 10s, and dried in a three-stage oven. The temperatures of the ovens at each level were 55°C, 60°C, and 70°C. After drying, the lithium-ion battery coated with aramid polymer was obtained. diaphragm. The lithium-ion battery separator coated with the aramid ...

Embodiment 2

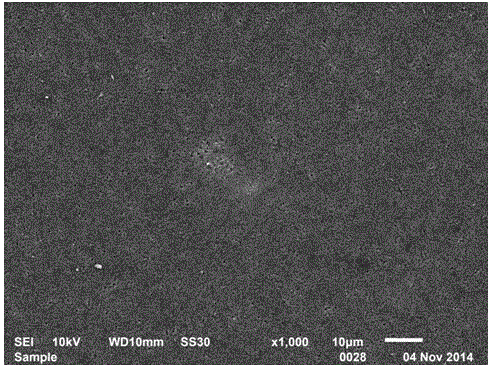

[0044] Weigh 2.85kg of DMF, add 0.05kg of polyvinyl alcohol powder, stir until completely dissolved, add 5kg of para-aramid polymer to the above solution, the aramid content is 13.75%, and the aramid molecular weight is 40,000-70,000. After stirring evenly, add 2kg of isopropanol and 0.05kg of vinylpyrrolidone and vinyl acetate (PVP-VA) copolymer adhesive in turn while stirring, and disperse evenly to prepare aramid fiber slurry; select a corona polymer with a thickness of 22 μm The imide base film has a porosity of 44%. The aramid slurry is coated on both sides of the base film by dip coating, and the coating speed is 5m / min. Pre-solidified for 15s in an environment with a humidity of 95%, washed with water for 15s, and dried in a three-stage oven. The temperatures of the ovens at each level were 45°C, 50°C, and 60°C. After drying, aramid polymer-coated lithium-ion batteries were obtained. diaphragm. The thickness of the lithium-ion battery separator coated with the aramid f...

Embodiment 3

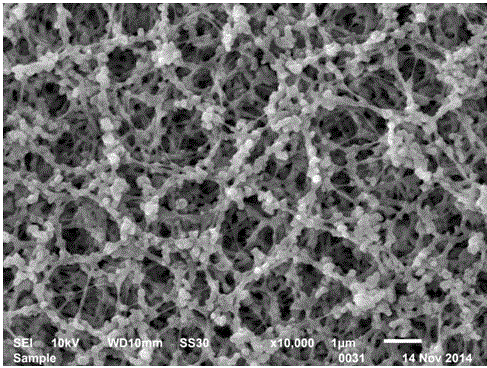

[0046]Weigh 1.45kg of DMSO, add 0.05kg of polyacrylamide, stir until completely dissolved, add 7.5kg of para-aramid polymer to the above solution, the active ingredient of aramid (the active ingredient of aramid is the content contained in the polymer) The mass percentage of aramid fiber) is 12.5%, and the molecular weight of aramid fiber is 10,000-30,000. After stirring evenly, add 0.8kg of ethyl acetate and 0.2kg of vinylpyrrolidone and vinyl acetate (PVP-VA) copolymer adhesive The aramid fiber slurry was evenly dispersed to prepare the aramid fiber slurry; the polypropylene base film with a thickness of 32 μm was selected, and the porosity was 60%, and the aramid fiber slurry was coated on one side of the base film by gravure coating, and the coating speed was 30 m / min. Pre-solidified for 5s in an environment with a humidity of 95%, washed with water for 15s, and dried in a three-stage oven. The temperatures of the ovens at each level were 60°C, 65°C, and 55°C. After dryin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com