Mold and method for manufacturing intermittent-fissure rock mass simulating test piece

A technology for fractured rock mass and specimen, which is applied in the field of making molds for simulating specimens of intermittent fractured rock mass, can solve the problems of deflection, difficult to discharge air bubbles, and difficult to remove the mold, and achieves accurate fracture positioning, easy pouring and removal. Die convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

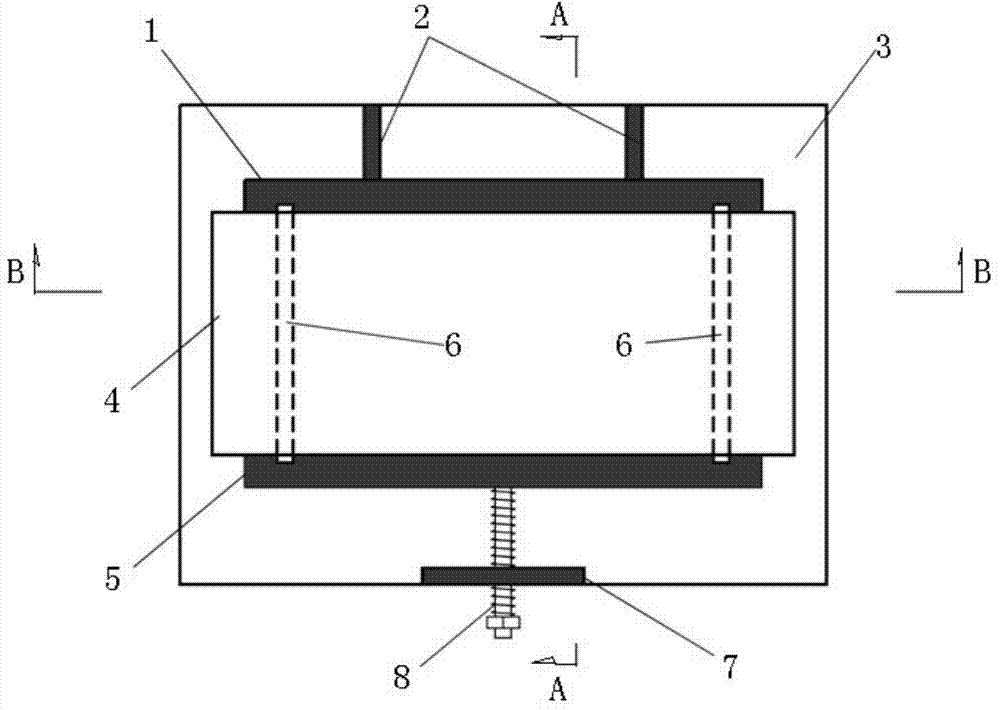

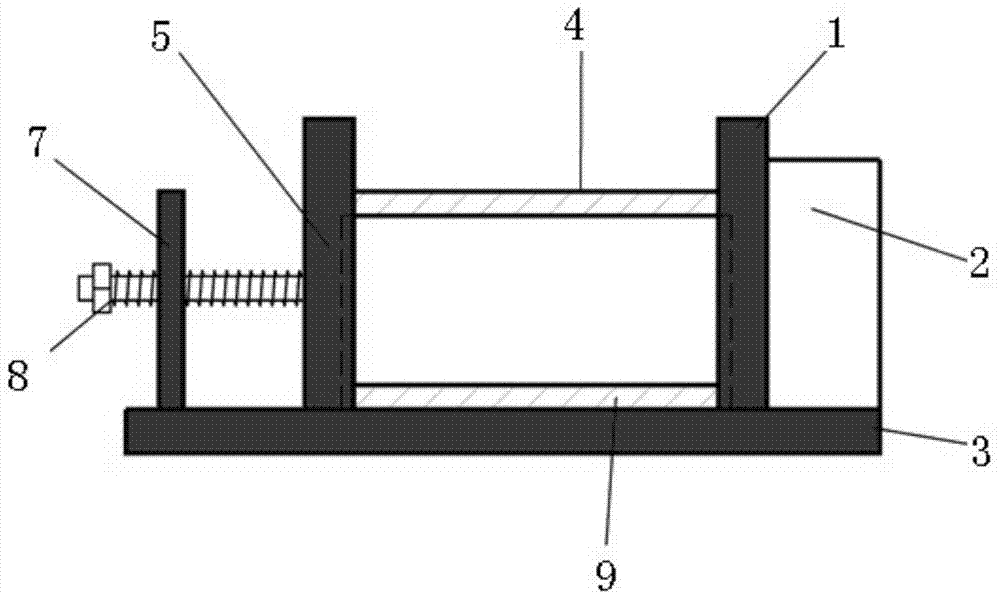

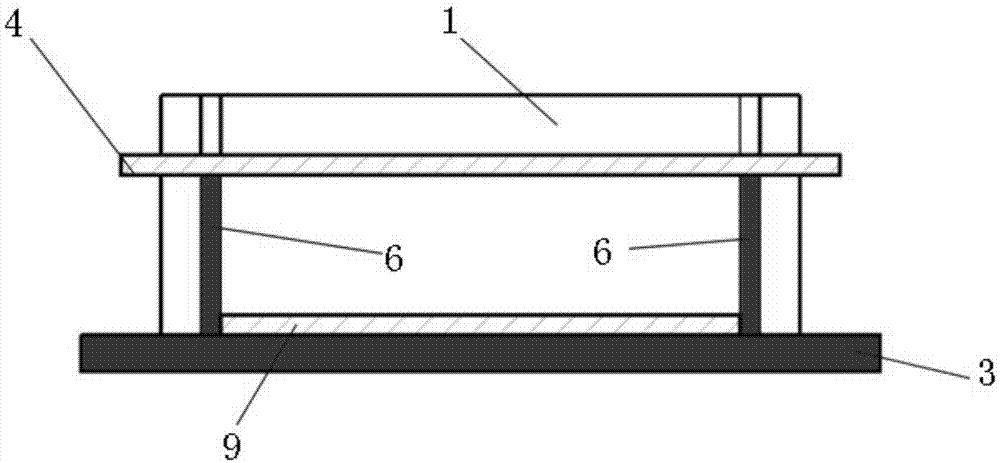

[0043] like figure 1 , figure 2 , image 3 As shown, including bottom plate, fixed long side plate, movable long side plate, movable short side plate, stiffener, bolted end plate, bolts, grooved top cover plate and grooved bottom backing plate, etc.

[0044] Bottom plate, fixed long side plate, movable long side plate, movable short side plate, stiffener plate, bolt end plate, bolts are all made of stainless steel or ordinary steel, while the grooved top cover plate and grooved bottom backing plate are made of acrylic material .

[0045] The fixed long side plates are connected to the bottom plate with screws, the bolted end plates and stiffeners are welded to the bottom plate, and the movable long side plates are supported on the bottom plate by means of bottom plate screws (not shown in the figure) and side bolts. The two movable short side panels are inserted through the grooves on the fixed long side panel and the movable long side panel.

[0046] like Figure 4 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com