Powder-acrylate composite grouting material and preparation method and application thereof

An acrylate and grouting material technology, which is applied to building insulation materials, mining equipment, shaft equipment, etc., can solve the problem of not involving the production process of acrylate grouting liquid, no description of acrylate composite grouting materials, and insufficient cohesiveness of concrete interface, etc. problem, to achieve the ideal grouting effect, increase strength and elasticity, and improve the effect of bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

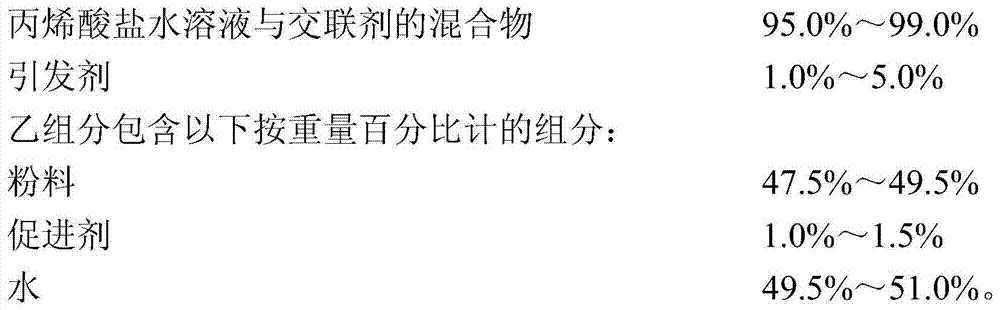

Method used

Image

Examples

Embodiment 1

[0052] (1) Preparation of mixture of acrylate salt solution and crosslinking agent

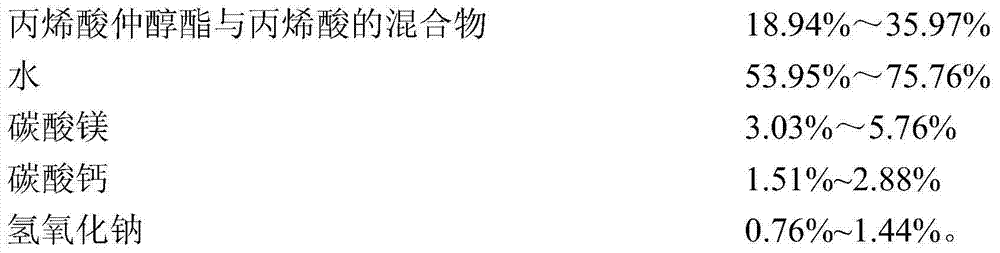

[0053] Add 79.26g of acrylic acid into a reactor with a reflux condenser, heat to 45°C, and add dropwise a mixture of 60.0g of 2-propanol, 0.42g of concentrated sulfuric acid and 0.21g of hydroquinone under stirring. The mixed solution was heated up to 120°C after the dropwise addition and continued to react for 6 hours. When the pH=2.60 was measured as the end point of the reaction, it was cooled to obtain a mixture of 2-propanol acrylate and acrylic acid, which was set aside;

[0054]Add 100 g of the mixture of 2-propanol acrylate and acrylic acid for use into the reactor, add 150 g of water and stir evenly, slowly add 16 g of magnesium carbonate and 8 g of calcium carbonate in batches under agitation, open the reactor jacket cooling water , and start the decompression device to remove the carbon dioxide gas generated by the neutralization reaction, continue to react for 2 hours, finally add...

Embodiment 2

[0063] (1) Preparation of the mixture of acrylate aqueous solution and crosslinking agent

[0064] Add 79.26 g of acrylic acid into a reactor with a reflux condenser, heat it to 45 ° C, and add dropwise 102.0 g of 2-hexanol, 0.54 g of p-toluenesulfonic acid and 0.27 g of hydroquinone under stirring. The prepared mixed solution was heated to 120° C. and continued to react for 6 hours after the dropwise addition, and the reaction end point was measured when pH=2.60, and cooled to obtain a mixture of 2-hexanol acrylate and acrylic acid, which was used for subsequent use;

[0065] Add 75g of the mixture of 2-hexanol acrylate and acrylic acid for standby into the reactor, add 150g of water and stir evenly, slowly add 12g of magnesium carbonate and 6g of calcium carbonate in batches under stirring, open the reactor jacket cooling water , and start the decompression device to remove the carbon dioxide gas generated by the neutralization reaction, continue the reaction for 2 hours, fi...

Embodiment 3

[0074] (1) Preparation of the mixture of acrylate aqueous solution and crosslinking agent

[0075] 79.26g of acrylic acid was added to the reactor with reflux condenser, heated to 45°C, and 130.0g of 2-octanol, 0.62g of p-toluenesulfonic acid and 0.31g of 2,6-octanol were added dropwise under stirring. The mixed solution prepared by di-tert-butyl-p-cresol was heated to 120° C. and continued to react for 6 hours after the dropwise addition. When pH=2.60 was determined, the reaction end point was determined, and the mixture was cooled to obtain a mixture of 2-octanol acrylate and acrylic acid, which was used for later use;

[0076] Add 50 g of the mixture of 2-octanol acrylate and acrylic acid for subsequent use into the reactor, add 200 g of water and stir evenly, slowly add 8 g of magnesium carbonate and 4 g of calcium carbonate in batches under agitation, open the reactor jacket cooling water , and start the decompression device to remove the carbon dioxide gas generated by t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com